Method and device for synchronous composite manufacturing of diamond micro-grating based on micro-addition and subtraction

A diamond and micro-grating technology, which is applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of diamond microstructure surface quality degradation, stress concentration at the edge of microstructure, and changes in the stress state of surrounding materials, so as to promote the application And industrialization, high quality and high aspect ratio, and the effect of improving the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] The surface of the diamond thin film sample was pretreated, and the diamond thin film sample was immersed in a suspension prepared by mass ratio of diamond micropowder and glycerin for 5 minutes by ultrasonic grinding, wherein the particle size of the diamond micropowder was 5 μm, and then immersed in anhydrous Ultrasonic cleaning in ethanol for 5 min, and then drying.

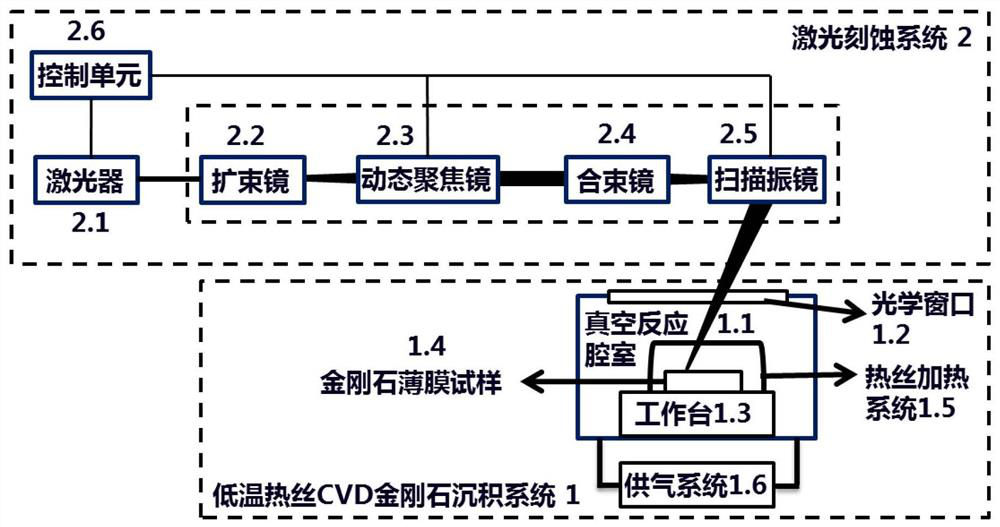

[0046] The pretreated diamond thin film samples were placed in figure 1 In the device shown, the low temperature hot wire CVD diamond deposition was carried out on the surface of the diamond film sample, and the process parameters used were: hydrogen flow rate of 800ml / min, methane flow rate of 50ml / min, hydrogen sulfide flow rate of 0.1ml / min, and reaction pressure of 10 Torr. , the hot wire temperature is 2100-2200 °C, the substrate temperature is 250 °C; the bias current is 4.0A, and the deposition time is 50 hours.

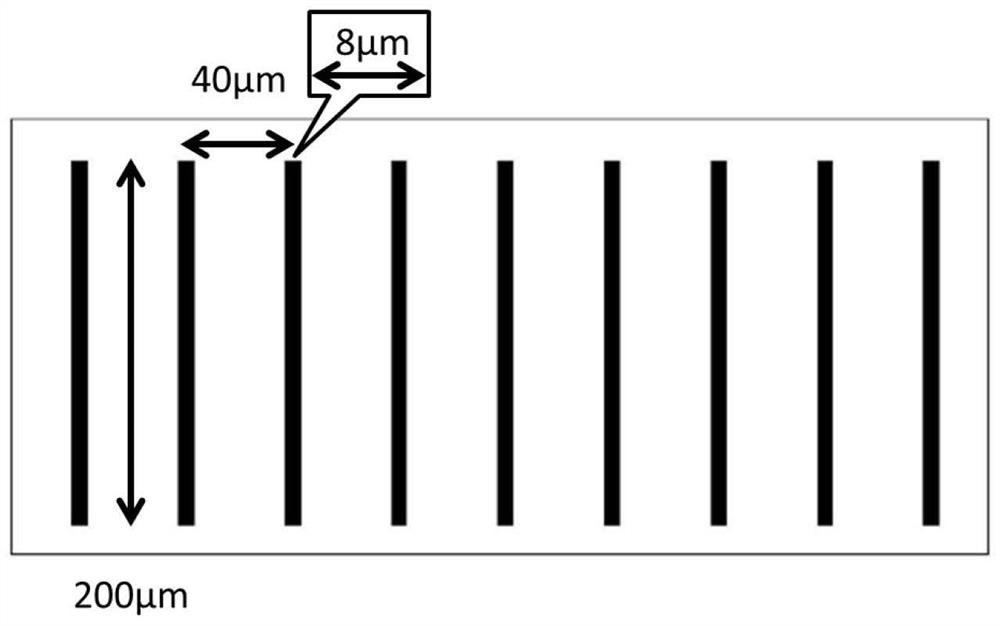

[0047] At the same time of low temperature hot wire CVD diamond deposition, laser ...

example 2

[0049] The surface of the diamond thin film sample was pretreated, and the diamond thin film sample was immersed in a suspension prepared by mass ratio of diamond micropowder and glycerin for 5 minutes by ultrasonic grinding, wherein the particle size of the diamond micropowder was 5 μm, and then immersed in anhydrous Ultrasonic cleaning in ethanol for 5 min, and then drying.

[0050] The pretreated diamond thin film samples were placed in figure 1 In the device shown, low-temperature hot-wire CVD diamond deposition was performed on the surface of the diamond film sample, and the process parameters used were: hydrogen flow rate of 1000ml / min, methane flow rate of 100ml / min, hydrogen sulfide flow rate of 0.4ml / min, and reaction pressure of 15 Torr. , the hot wire temperature is 2100-2200 °C, the substrate temperature is 100 °C; the bias current is 1.0A, and the deposition time is 80 hours.

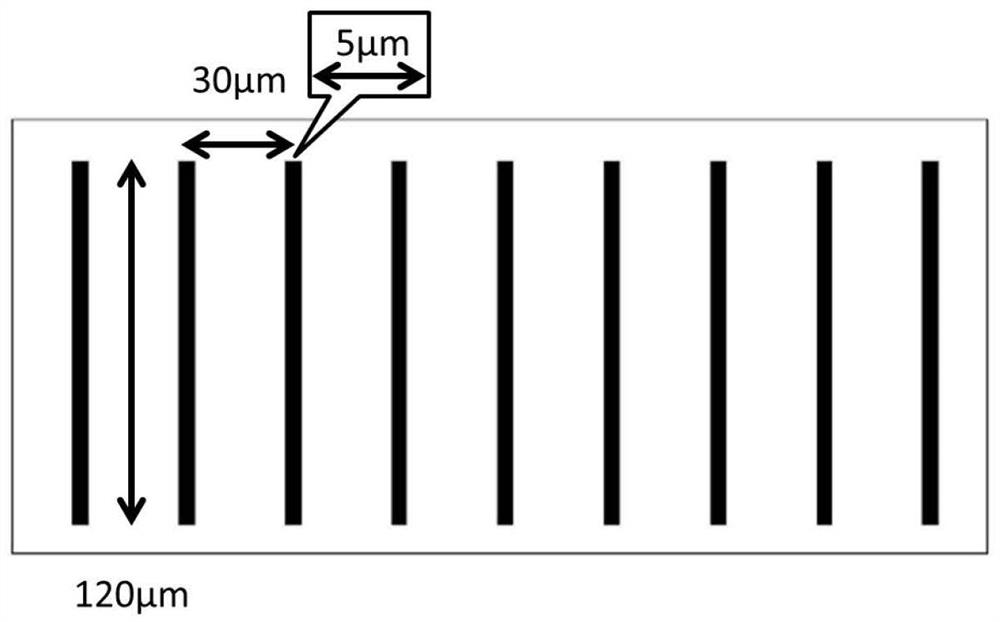

[0051] At the same time of low temperature hot wire CVD diamond deposition, laser etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com