Marching type automatic gripping feeding device

An automatic feeding, step-by-step technology, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of large device occupancy, maintaining the horizontal posture of the clamping end, deformation and damage of the outlet plate edge, etc. Occupied space, reduced necessary height, increased degree of freedom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

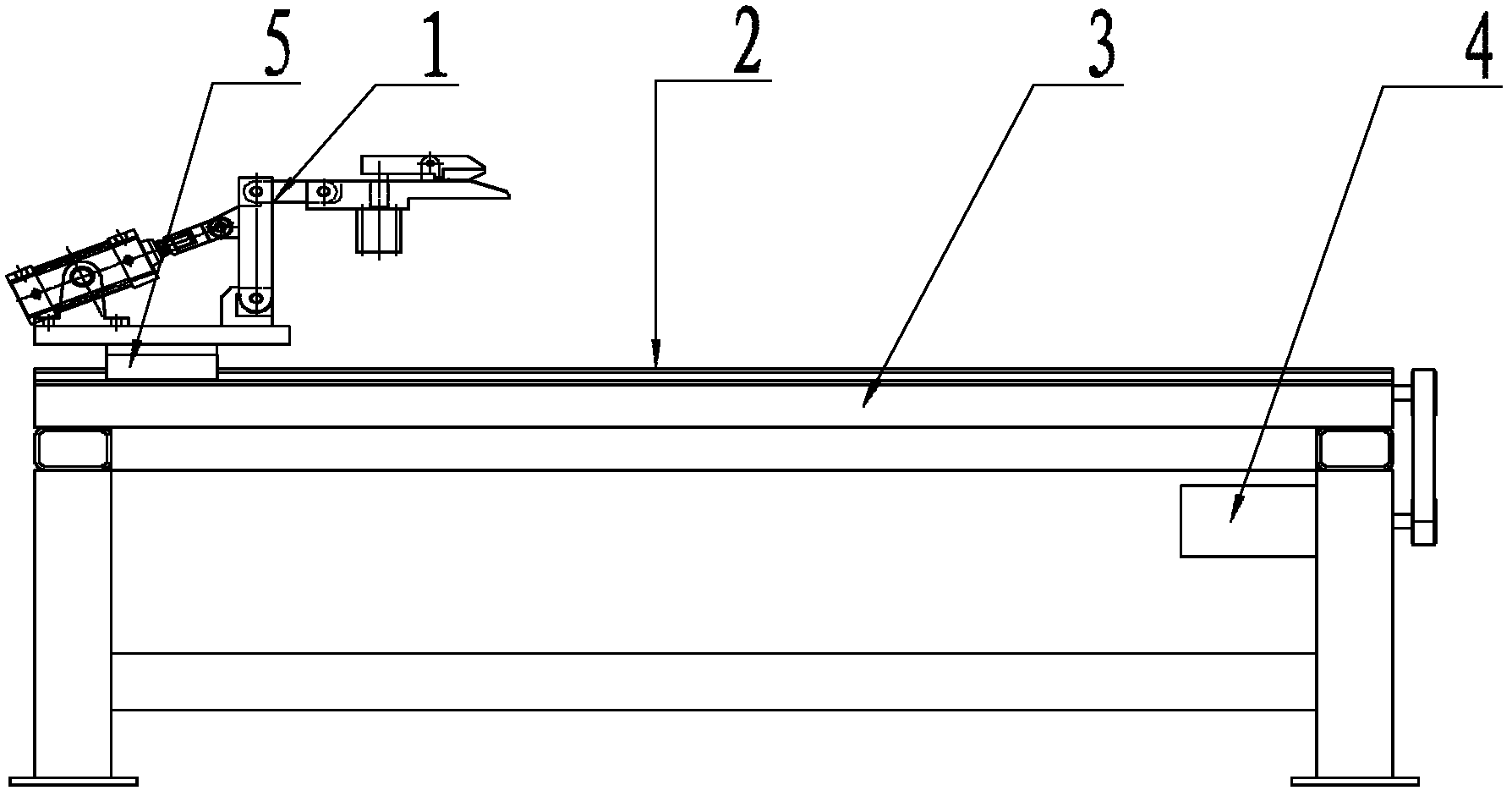

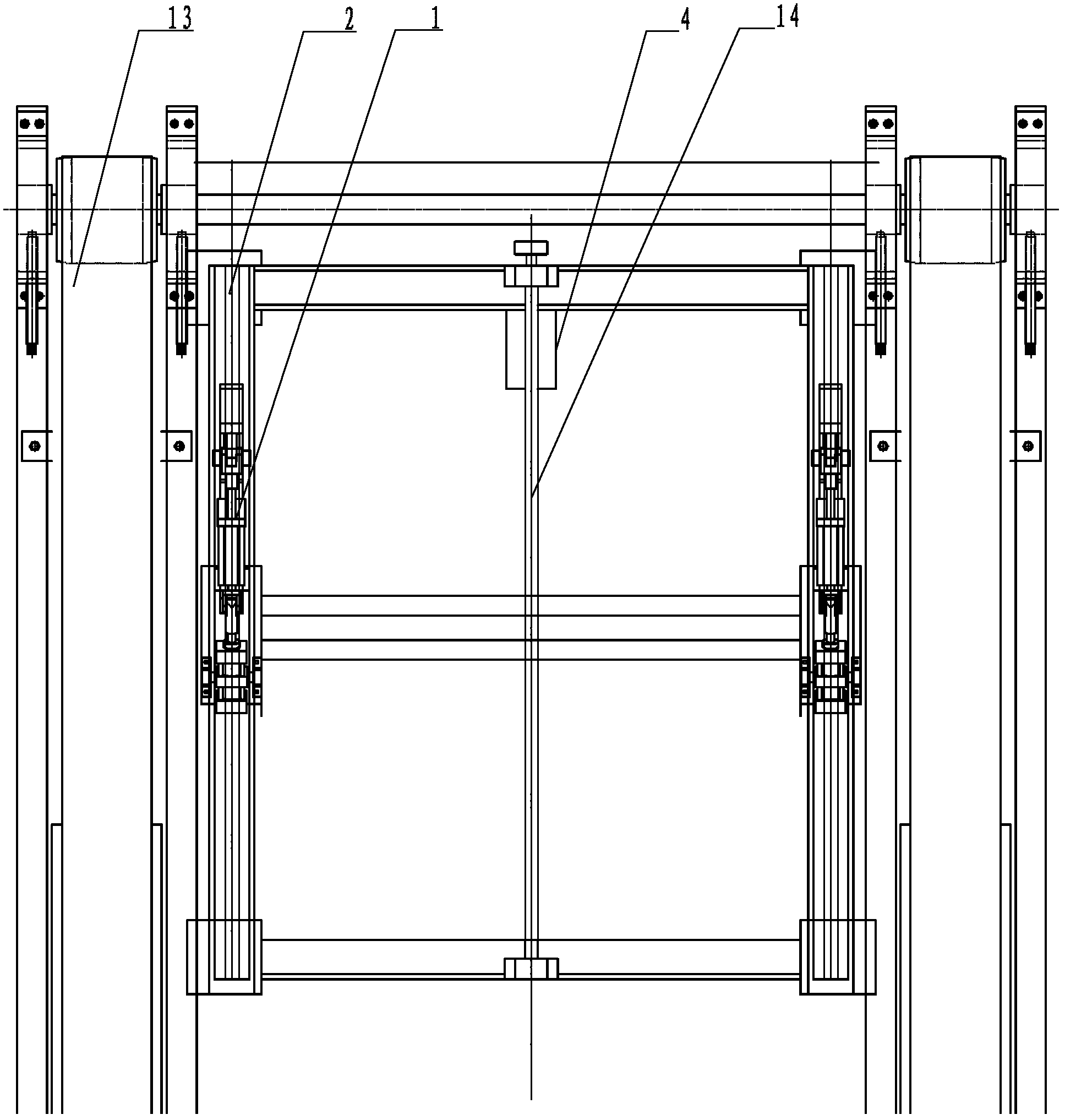

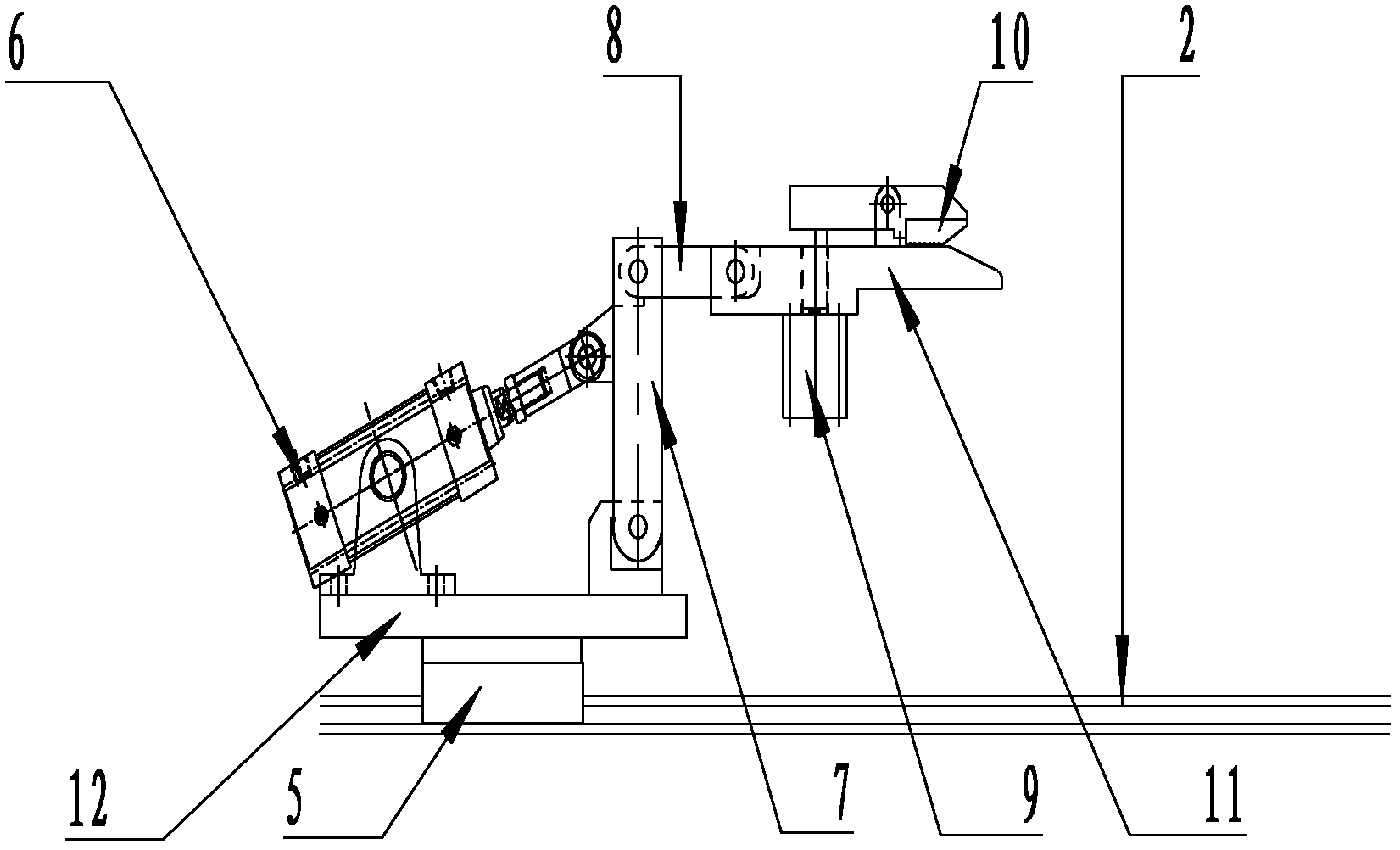

[0011] Pneumatic clamps 1 are fixedly installed on sliders 5 respectively through bases 12, and sliders 5 slide synchronously on two parallel sliding guide rails 2 respectively. The sliding guide rails 2 are supported by brackets 3, and a liftable belt conveyor 13 is installed on the outside of them. , The ball screw 14 is installed in the middle of the two sliding guide rails 2 and is parallel to the guide rails. The ball screw 14 is driven by the servo motor 4 and drives the slider 5 on the sliding guide rail 2 . Pneumatic clamp 1 comprises cylinder 6, connecting rod 7, hinge 8, thin cylinder 9, upper clamping plate 10 and lower clamping plate 11, and the center of gravity of upper clamping plate (10) is at the tail end of a certain distance from pin shaft, and cylinder 6 and connecting rod 7 The bottom ends of the cylinders are respectively hinged on the bracket through the pin shaft, the pull rod of the cylinder 6 is hinged with the middle part of the connecting rod 7 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com