Improved cutter

A cutting machine and fuselage technology, which is applied to metal sawing equipment, attachments of sawing machines, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

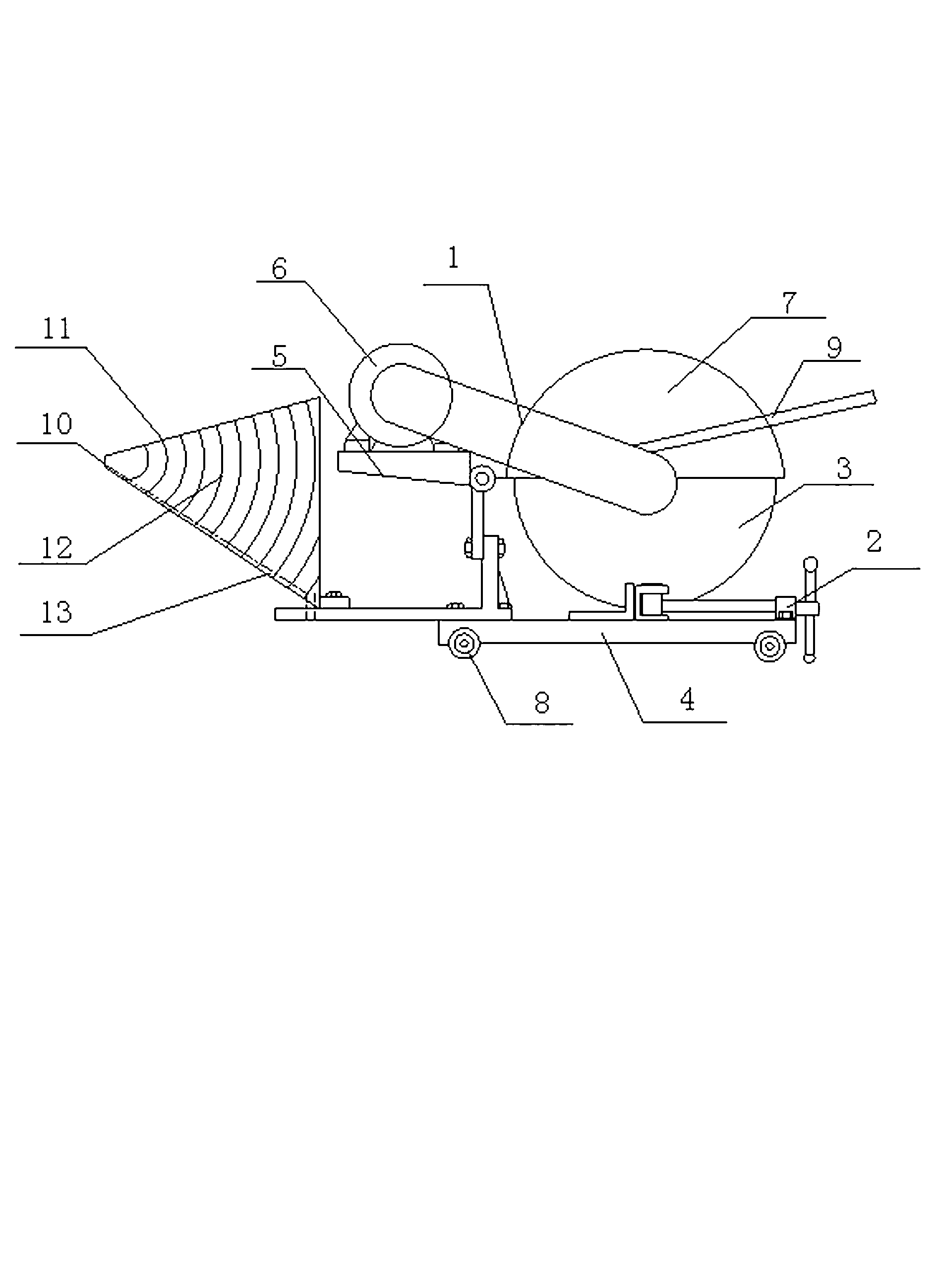

[0013] Such as figure 1 As shown, an improved cutting machine of the present invention includes a fuselage 1, a bracket, a caliper 2, and a saw blade 3. The bracket is composed of a lower base 4 and an upper support plate 5, and a motor 6 is installed at one end of the fuselage 1. A saw blade cover 7 is installed on the top of the saw blade 3, a caliper 2 is installed on the base 4, a moving roller 8 is arranged under the base 4, an operating handle 9 is installed on the body 1, and a protective cover is also provided on the front of the cutting machine 10. The protective cover 10 includes a casing 11, the casing 11 is fixed on the extension plate of the base 4, the inner wall of the casing 11 is provided with flow guiding ribs 12, and the lower part of the casing 11 is provided with a feeding chute 13, and the casing 11 The shape is arc-shaped, and the guide ribs 12 are arranged on the inner wall of the casing 11 in a helical shape with the upper part smaller and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com