Full-automatic ash brushing machine

A fully automatic and dust-cleaning technology, which is applied in the direction of construction and building construction, can solve the problems of affecting human health, inhaling harmful substances, and expensive labor costs, and achieves the effects of protecting human health, reducing labor force, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

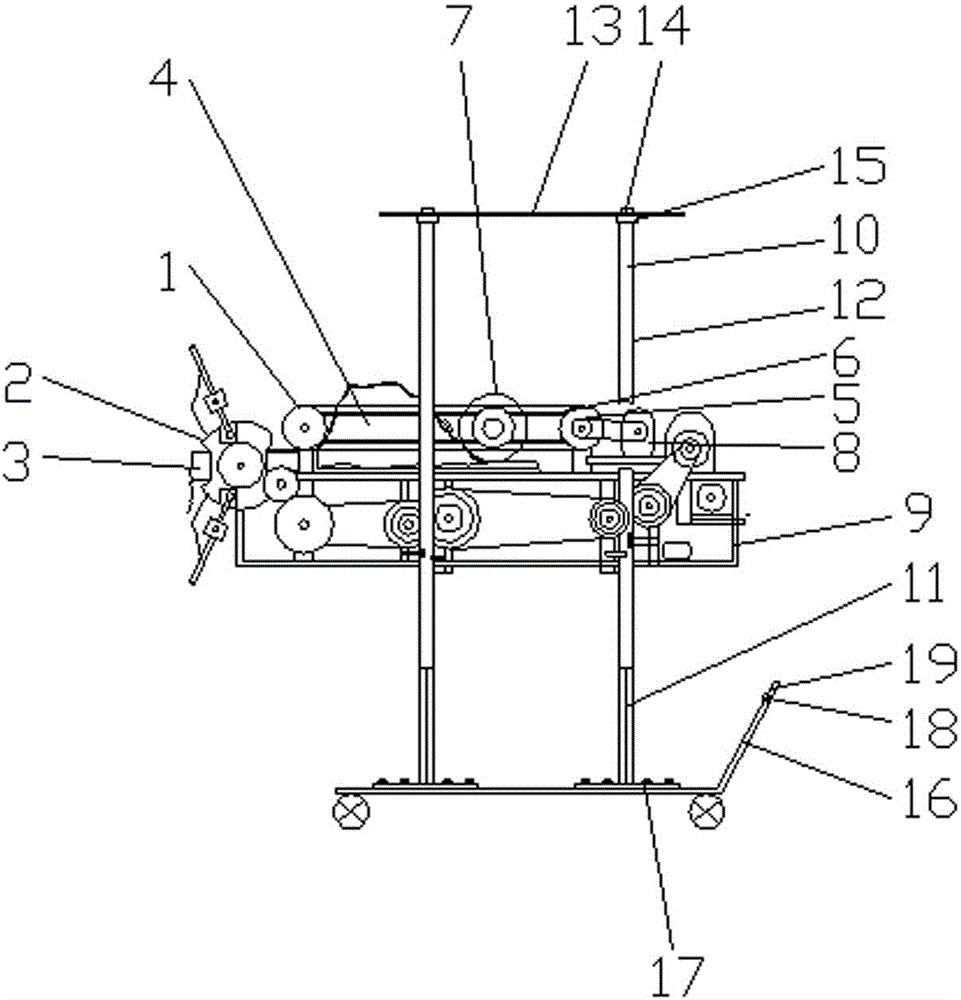

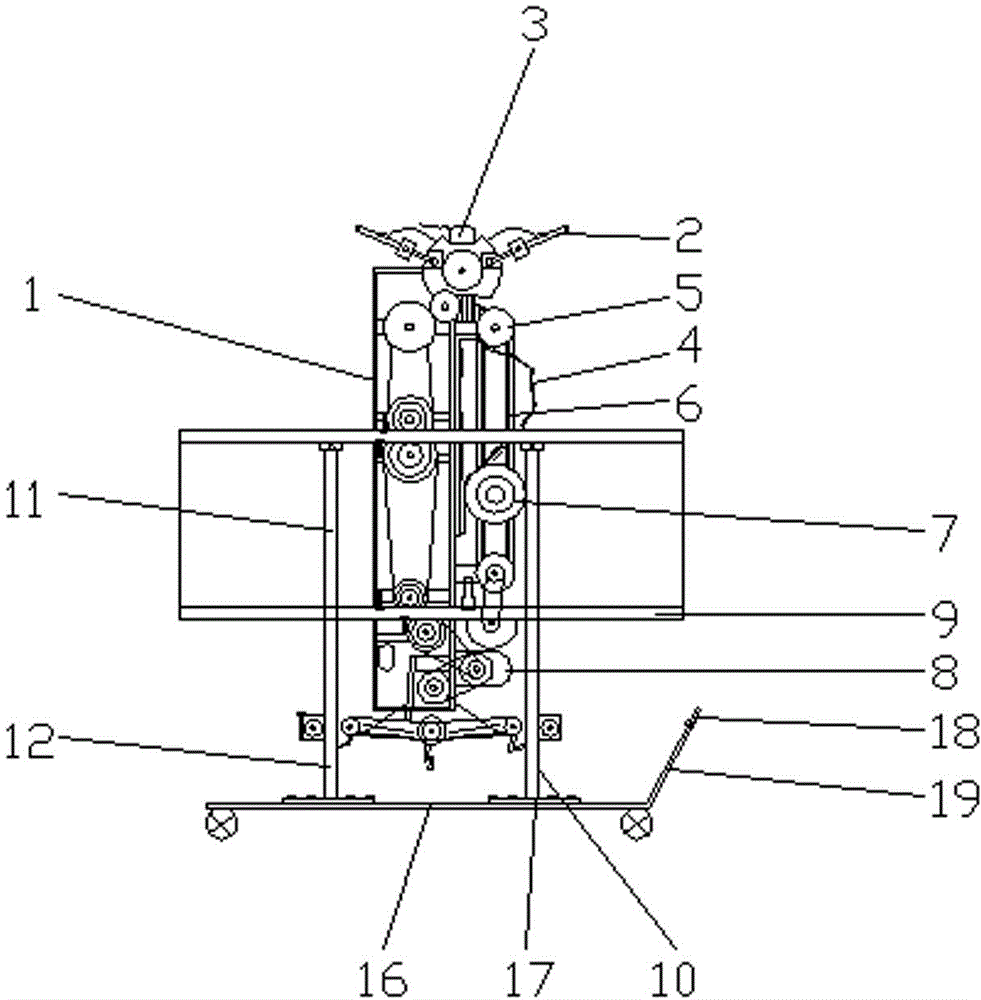

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] see figure 1 and figure 2 , a full-automatic brushing machine, comprising a scraper device 1, a scraper 2 is arranged at the upper and lower sides of the scraper device 1, and a discharge port 3 is provided at the front end of the scraper device 1, and the discharge port 3 It is connected with the charging bag 4 at the rear end of the scraper 2 device 1, and a pressing sprocket 5 is respectively arranged at the front and rear ends of the charging bag 4, and a pressing chain 6 is arranged between the pressing sprockets 5, and the pressing The material sprocket 5 is fixed on a shelf spanning the front and rear ends of the charging bag 4, and a button that can roll on the pressing material chain 6 can squeeze the charging bag 4 and is connected with the travel switch signal on the pressing material chain 6. The connected pressing roller 7, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com