Contact controller for nozzle of injection molding machine

A technology of control device and injection molding machine, which is applied in the field of nozzle contact control device, and can solve problems such as excessive load on the mechanism part and poor forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

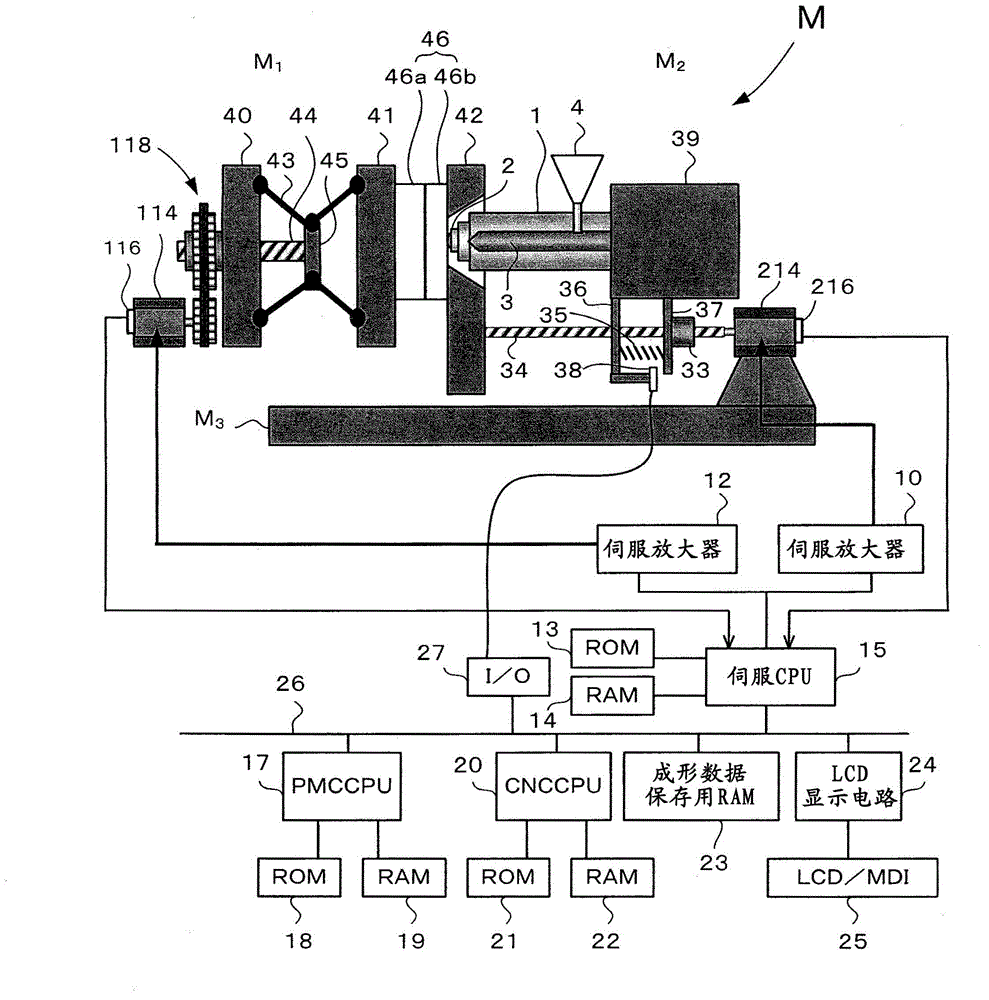

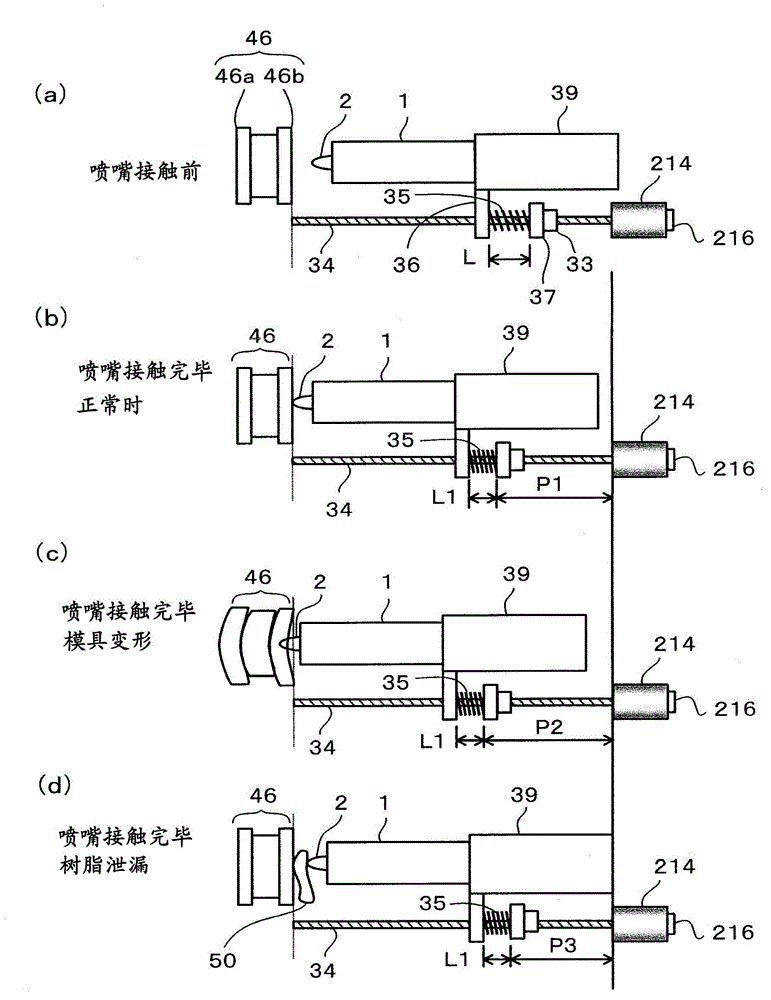

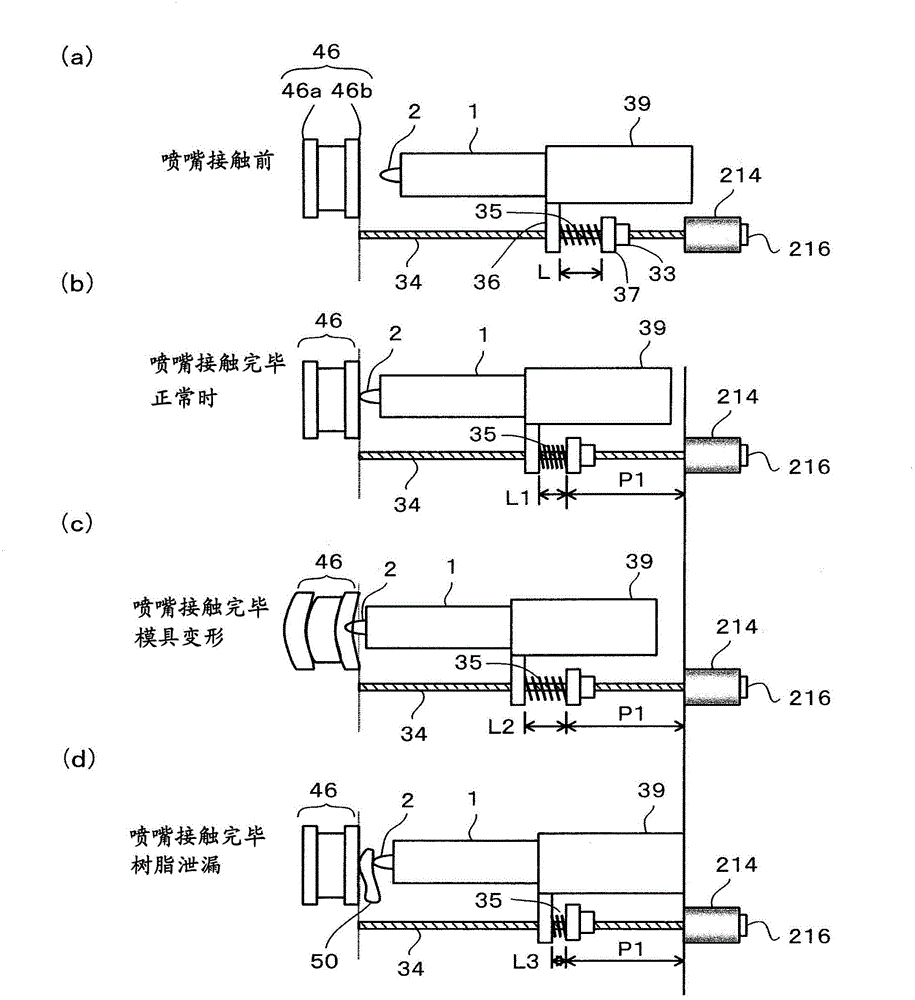

[0022] use figure 1 An injection molding machine to which the nozzle contact control device of the present invention is applied will be described.

[0023] Injection molding machine M on machine base M 3 Clamping part M on top 1 and the injection part M 2 . Injection Department M 2 The resin material (powder) is heated and melted, and the melted resin is injected into the cavity of the mold 46 . A nozzle 2 is attached to the front end of the injection cylinder 1 . A screw 3 is inserted into the injection cylinder 1 . Furthermore, a hopper 4 for supplying a resin material (not shown) into the injection cylinder 1 is attached to the side of the injection cylinder 1 .

[0024] Clamping part M 1 The mold 46 (the movable side mold 46a, the fixed side mold 46b) is opened and closed. The clamping part M 1 Equipped with: a fixed platen 42 on which the fixed side mold 46a is mounted; a movable platen 41 on which the movable side mold 46a is mounted so as to face the fixed si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com