Wiper blade assembly

A wiper and component technology, applied in the field of wiper components, to achieve the effect of preventing lift and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

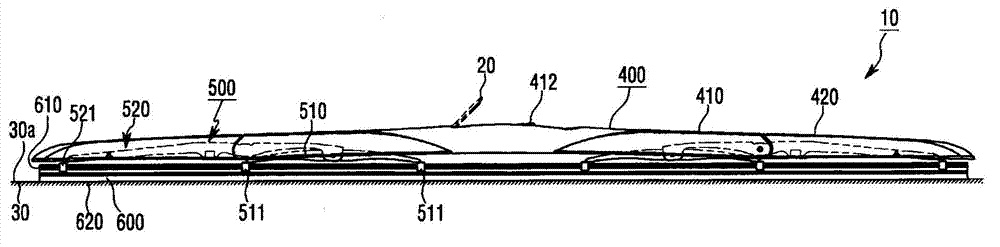

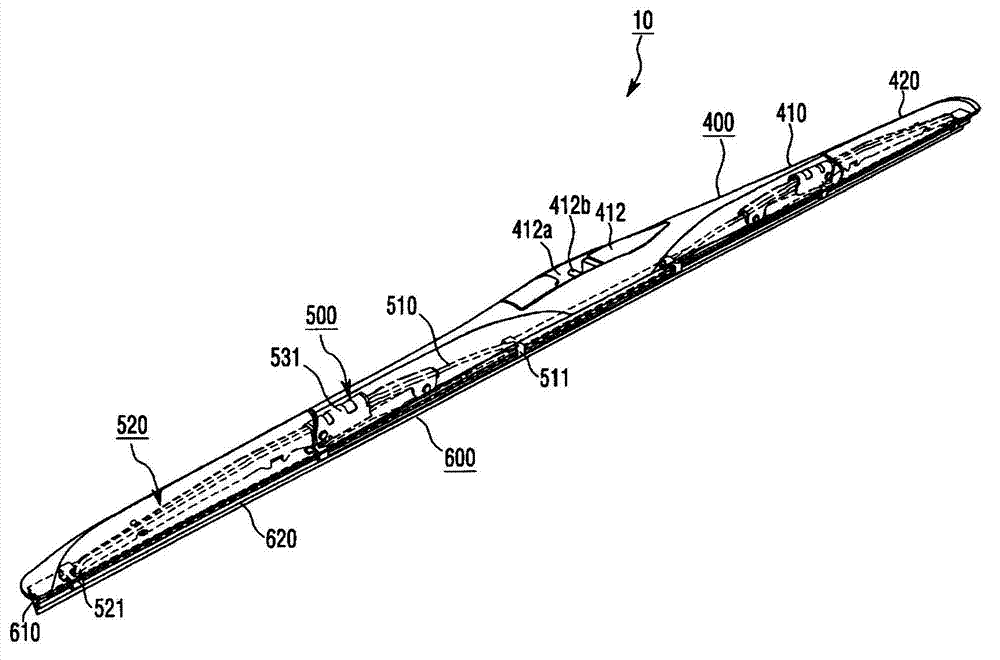

[0106] Figure 10a It is a perspective view which shows the 1st Example of the adapter part of the wiper blade of this invention.

[0107] Such as Figure 10a As shown, the adapter portion 200 of the present invention includes a central portion 212 and a pair of angled end portions 232 . The central portion 212 may include an insertion groove 222 formed in the center of the central portion 212 and connected to the connector 300 , and a first receiving groove 223 and a second receiving groove 224 adjacent to the lower end of the connector 300 .

[0108] The adapter part 200 is formed in a recessed part 242 substantially located at the center of the cover part 400 to connect the chuck part 412 . Preferably, the recessed portion 242 is in the shape of a trapezoid whose width narrows toward the wiper blade 600 , so that the finned portion 415a of the connecting clamp portion 415a as a part of the central finned portion 415 of the wiper blade can be aligned with the lower end por...

no. 2 Embodiment

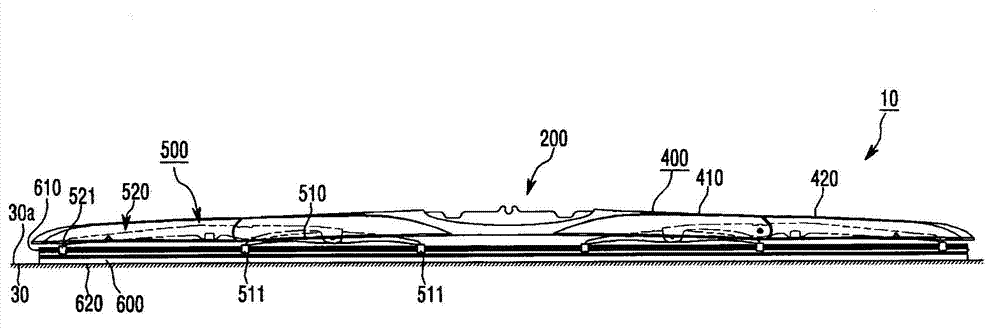

[0118] Figure 11a It is a perspective view which shows the 2nd Example of the adapter part of the wiper blade of this invention.

[0119] Such as Figure 11a As shown, the adapter part 201 is formed in the center of the cover part and includes an insertion slot 220 connected with the connector 300 .

[0120] The adapter part 201 is formed in a recessed part 240 located substantially in the center of the connecting chuck part 412 of the cover part 400 . Preferably, the recessed portion 240 is formed in a trapezoidal shape whose width narrows toward the wiper blade 600 , so that the fin portion 415 a of the connection clamp portion 415 a that is a part of the central fin portion 415 of the wiper blade can be aligned with the lower end portion of the clamp portion 412 . Connected morphogenesis. However, the form of the recessed portion 240 is not limited to a trapezoidal shape, and may also be formed in a U-shaped form. In this embodiment, the adapter part 201 does not need ...

no. 3 Embodiment

[0131] Figure 12a and Figure 12b It is a perspective view which shows the 3rd Example of the adapter part of the wiper blade of this invention.

[0132] Such as Figure 12a As shown, the adapter part 202 is formed in the recessed part 241 located approximately in the center of the connecting chuck part 412 of the cover part 400 . Preferably, the recessed portion 241 is formed in a trapezoidal shape whose width becomes narrower toward the wiper blade 600 , and the finned portion 415 a of the connecting clamp portion 415 a that is a part of the central finned portion 415 of the wiper blade can be connected with the lower end portion of the clamping portion 412 . Connected morphogenesis. However, the form of the recessed portion 241 is not limited to a trapezoidal shape, and may be formed in a U-shaped form. The adapter part 202 is formed such that its lower surface fits into the recessed part 241 .

[0133] Since the adapter part 202 is integrally formed with the cover pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com