Spring swing arm assembly and application method thereof

A rocker arm assembly and spring fixing technology, which is applied in the direction of aircraft accessories, wing leaf parts, door/window accessories, etc., can solve the problems of many operation steps, inconvenient maintenance work, and impact, so as to increase damping insurance, reduce operation steps, The effect of reducing the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

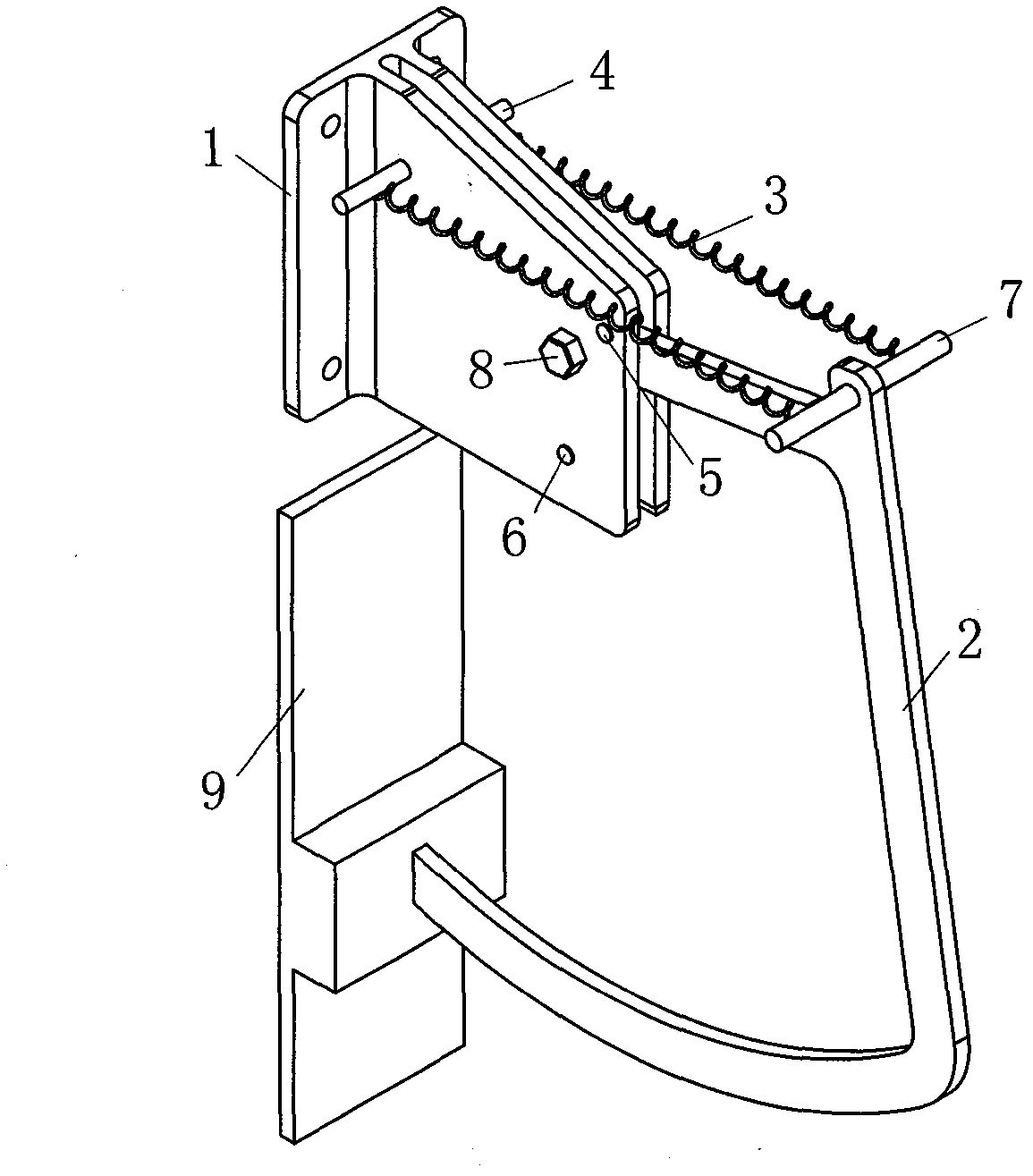

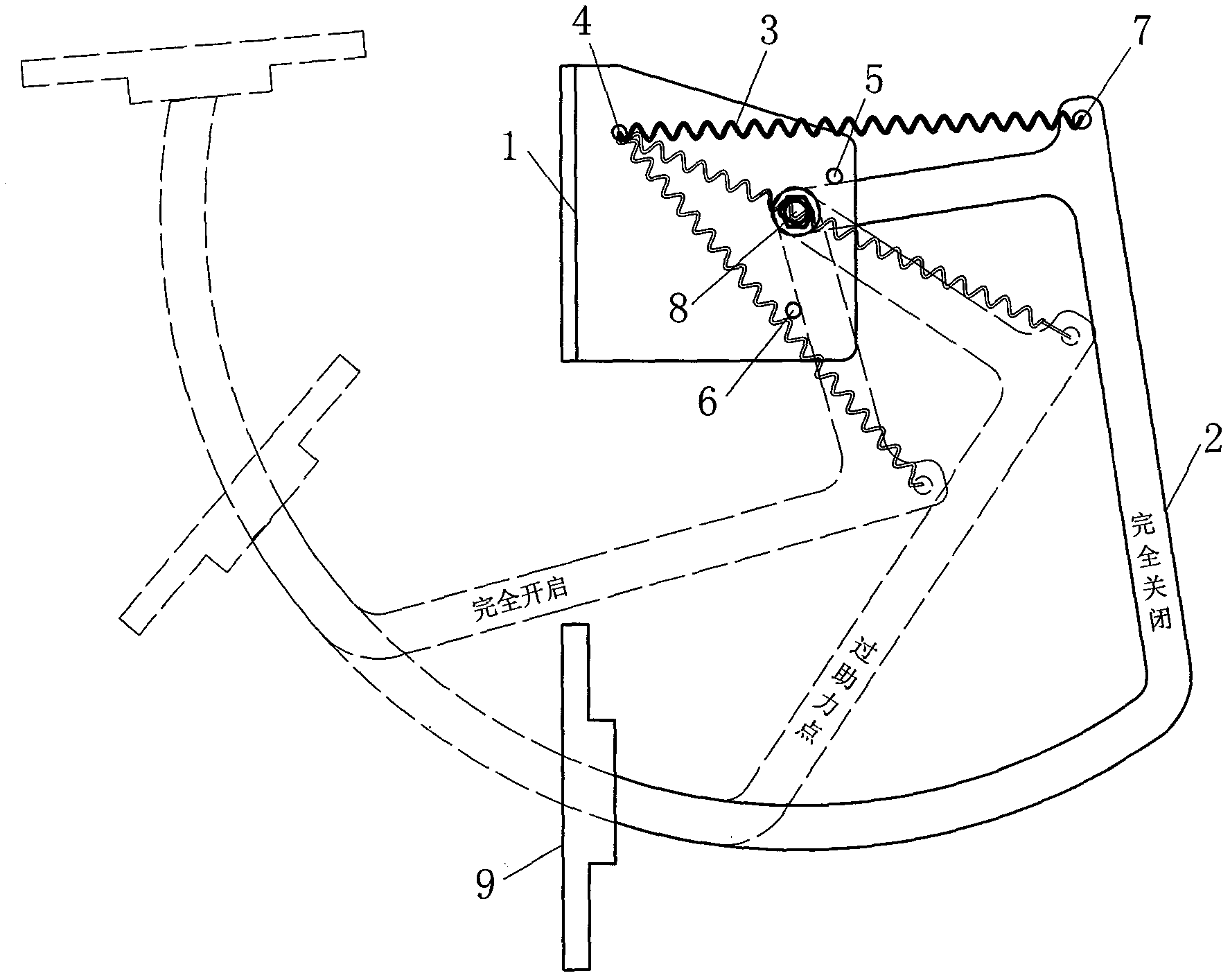

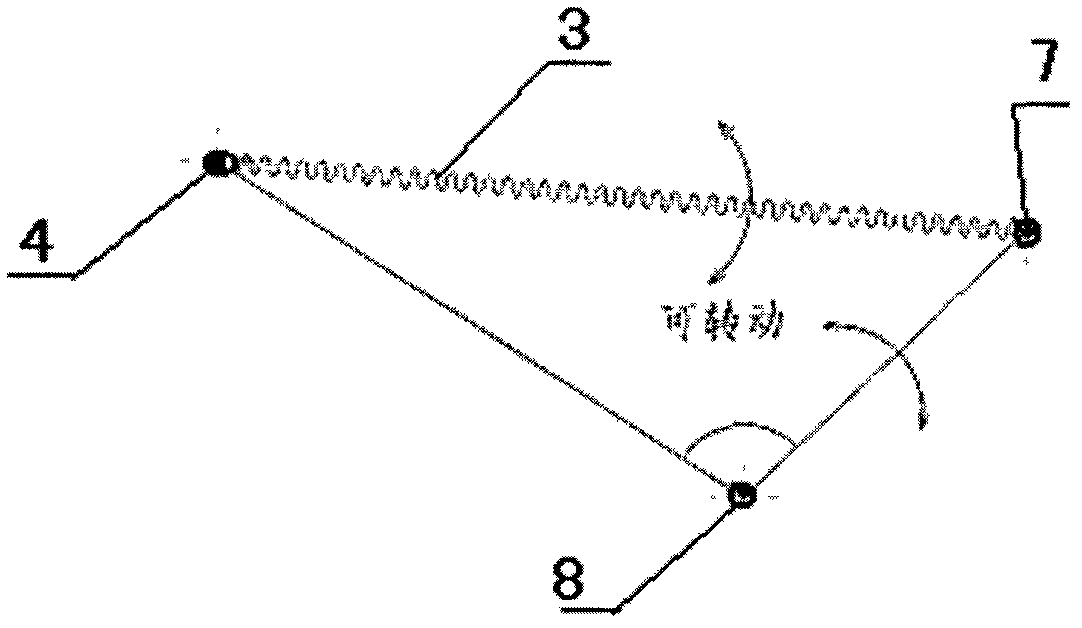

[0014] See the accompanying drawings, in implementation, see figure 2 , Support 1 and rocker arm 2 are machined from LY12-BCZYU plate; spring 3 is made of HB3-1-1×6×15II; first spring fixed point shaft 4 upper limit pin 5 and lower limit pin 6, the second 30CrMnSiA bar material is selected for use as the pin shaft 8 of the spring fixed point shaft 7 and the hinge point.

[0015] The support 1 is a T-shaped structure, and its bottom plane is used to connect with the aircraft body. The fixed body 10 protruding from the center of the support is used to fix the rocker arm 2 and the return spring 3. figure 1 The fixed body is a double-sided sandwich rigid body with a central groove, which is perpendicular to the bottom plane of the support; the rocker arm 2 is a rigid half-frame "ㄈ"-shaped connecting rod, and the front end of the rocker arm 2 passes through the pin shaft 8 Hinged on the fixed body 10 of the support, in order to limit the orbiting range of the rocker arm, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com