Carbonization activation furnace

A technology of activation furnace and furnace body, which is applied in the direction of carbon compounds, inorganic chemistry, chemical instruments and methods, etc. It can solve the problem of controlling the activation temperature at 400-650°C and controlling the activation temperature at 600-950°C, which cannot be fully contacted and is difficult to carbonize. temperature and other issues, to achieve the effect of suitable promotion and use, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

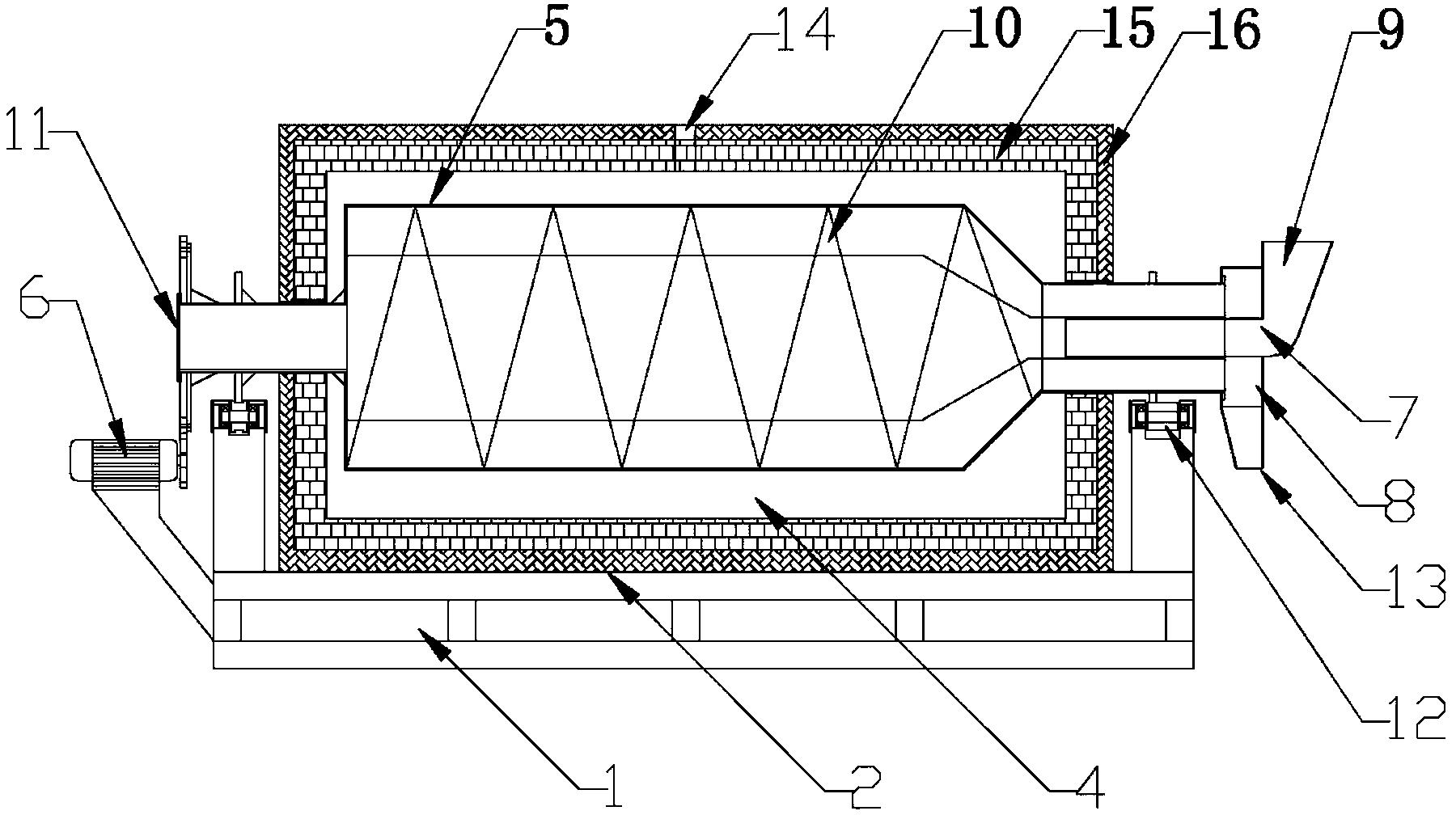

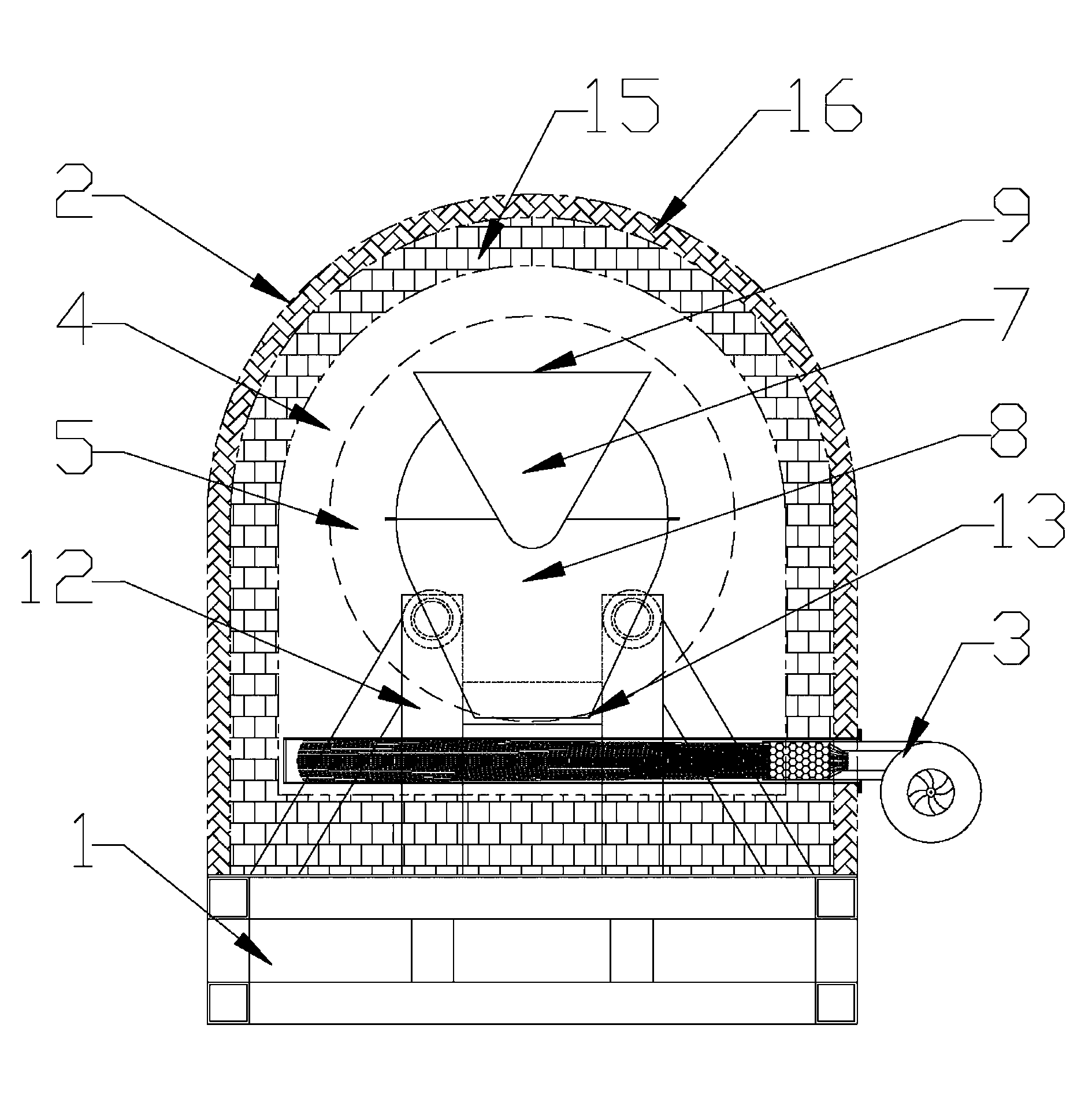

[0018] like figure 1 and figure 2 Shown: a carbonization activation furnace, which includes a base 1, a furnace body 2 and a combustion device 3, the furnace body 2 is installed on the base 1, wherein the furnace body 2 installed on the base 1 is composed of a refractory insulation layer 15 and an insulation surface layer Composed of 16, the insulation surface layer 16 is located on the outside of the refractory insulation layer 15, and the upper wall of the furnace body 2 is also provided with a smoke exhaust port 14 for exhausting flue gas, and the flue gas discharged from the smoke exhaust port 14 can be circulated Utilization; the combustion device 3 is installed on the side of the furnace body 2 and extends into the chamber 4 of the furnace body 2 . In the chamber 4, there is a drum 5 arranged horizontally, and the inner wall of the drum 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com