Novel polymer emulsifier and preparation method thereof

An emulsifier and emulsified explosive technology, which is used in offensive equipment, non-explosive/non-thermal agent components, explosives, etc., to achieve the effects of mature production technology, low cost and sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

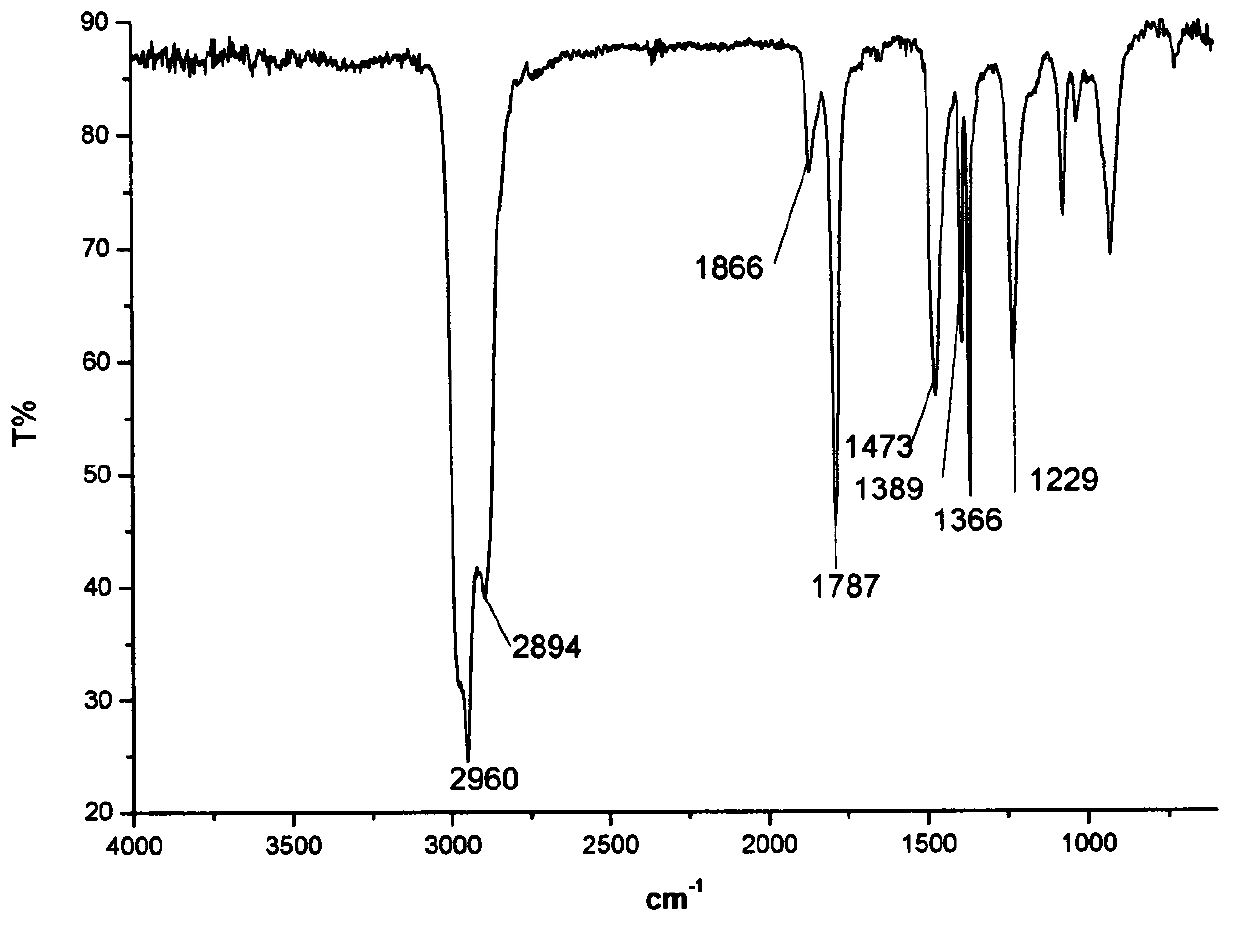

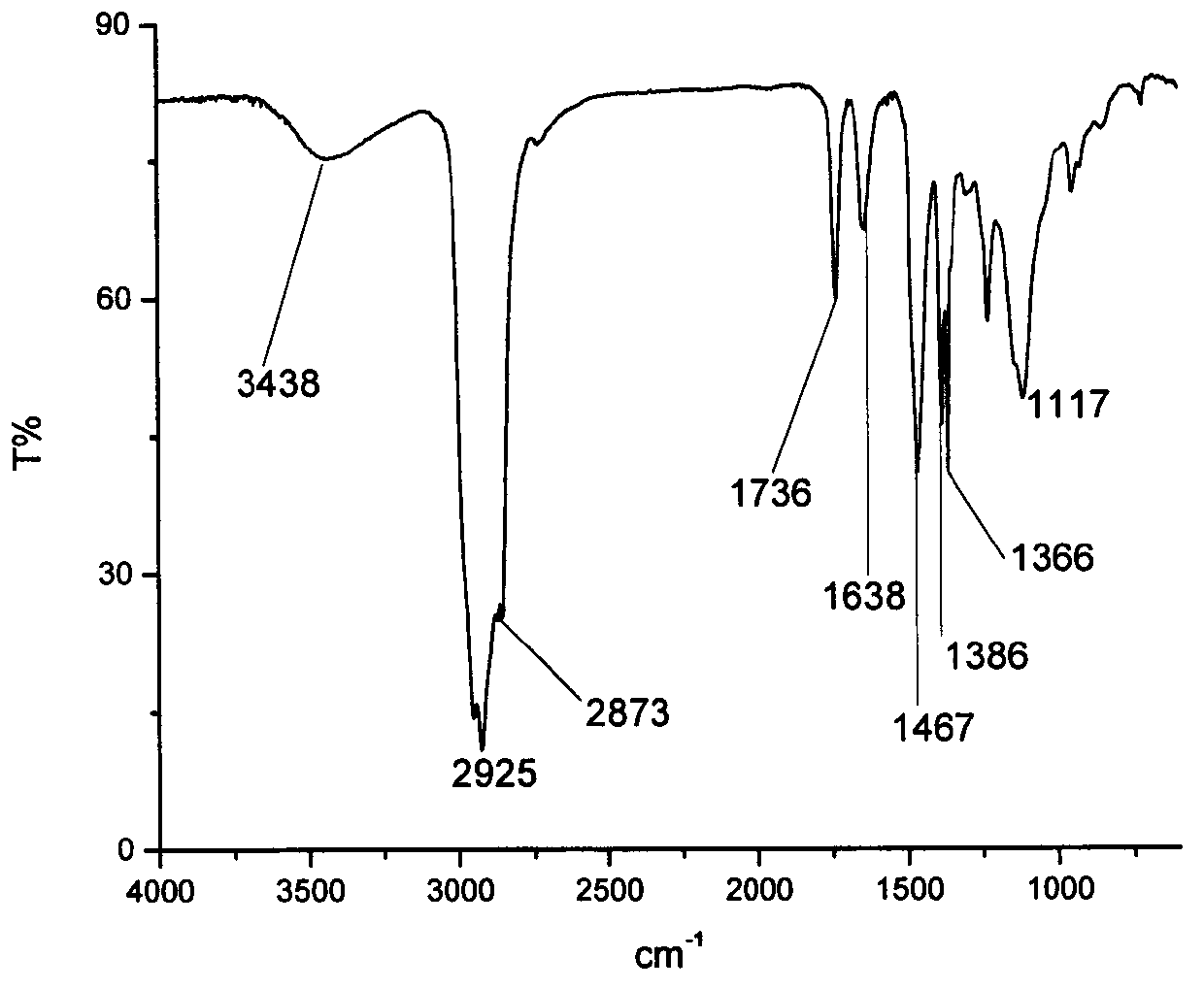

Image

Examples

Embodiment 1

[0022] Polyisobutylene succinic anhydride (molecular weight of isobutylene chain is 1000) 41.0g (0.037mol), fatty alcohol polyoxyethylene ether (7) (AEO 7 ) 18.4g (0.037mol), SN150 base oil 25.5g, under vacuum (-0.08~0.09MPa), heat up to 120°C, stir for 1.0h, add 3.7g (0.035mol) of diethanolamine, heat up to 145°C Continue to react for 2.5h to obtain the emulsifier PA of the present invention.

Embodiment 2

[0024] Polyisobutylene succinic anhydride (molecular weight of isobutylene chain is 1000) 37.5g (0.034mol), fatty alcohol polyoxyethylene ether (9) (AEO 9 ) 20.2g (0.034mol), SN150 base oil 26.0g, under vacuum (-0.08~0.09MPa), heat up to 100°C, stir for 2.0h, add 3.4g (0.032mol) of diethanolamine, heat up to 145°C Continue to react for 2.5h to obtain the emulsifier PB of the present invention.

Embodiment 3

[0026] Polyisobutylene succinic anhydride (molecular weight of isobutylene chain is 1300) 46.5g (0.033mol), fatty alcohol polyoxyethylene ether (7) (AEO 7 ) 16.5g (0.033mol), SN150 base oil 28.0g, under vacuum (-0.08~0.09MPa), heat up to 80°C, stir and react for 3.0h, add 3.3g (0.031mol) of diethanolamine, heat up to 155°C Continue to react for 2.0h to obtain the emulsifier PC of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com