Hydraulic-control double-stage well test blowout preventer

A blowout preventer and hydraulic control technology, applied in wellbore/well components, earthwork drilling, sealing/packaging, etc., can solve the problem of poor use effect of hydraulic control blowout preventer, difficulty in running well testing tools, and operational efficiency. It can reduce the difficulty of running in, improve the success rate of well testing operations, and reduce operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

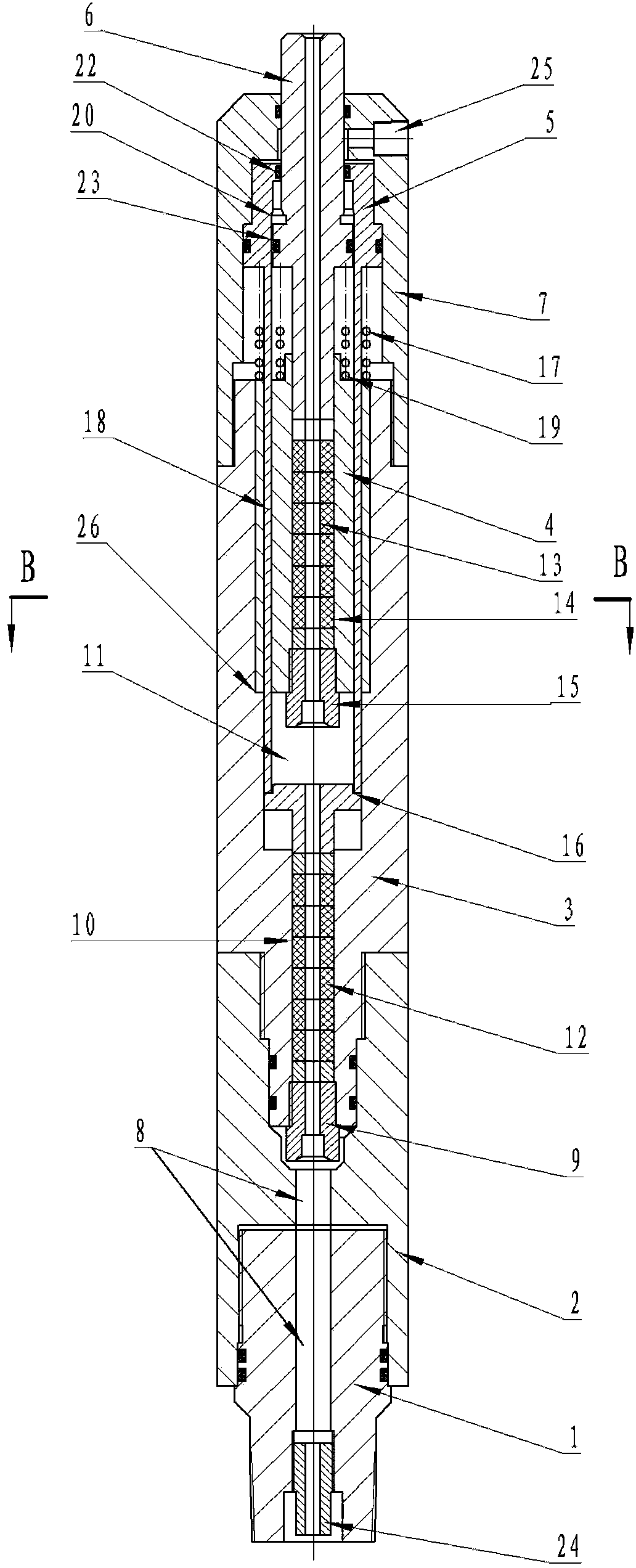

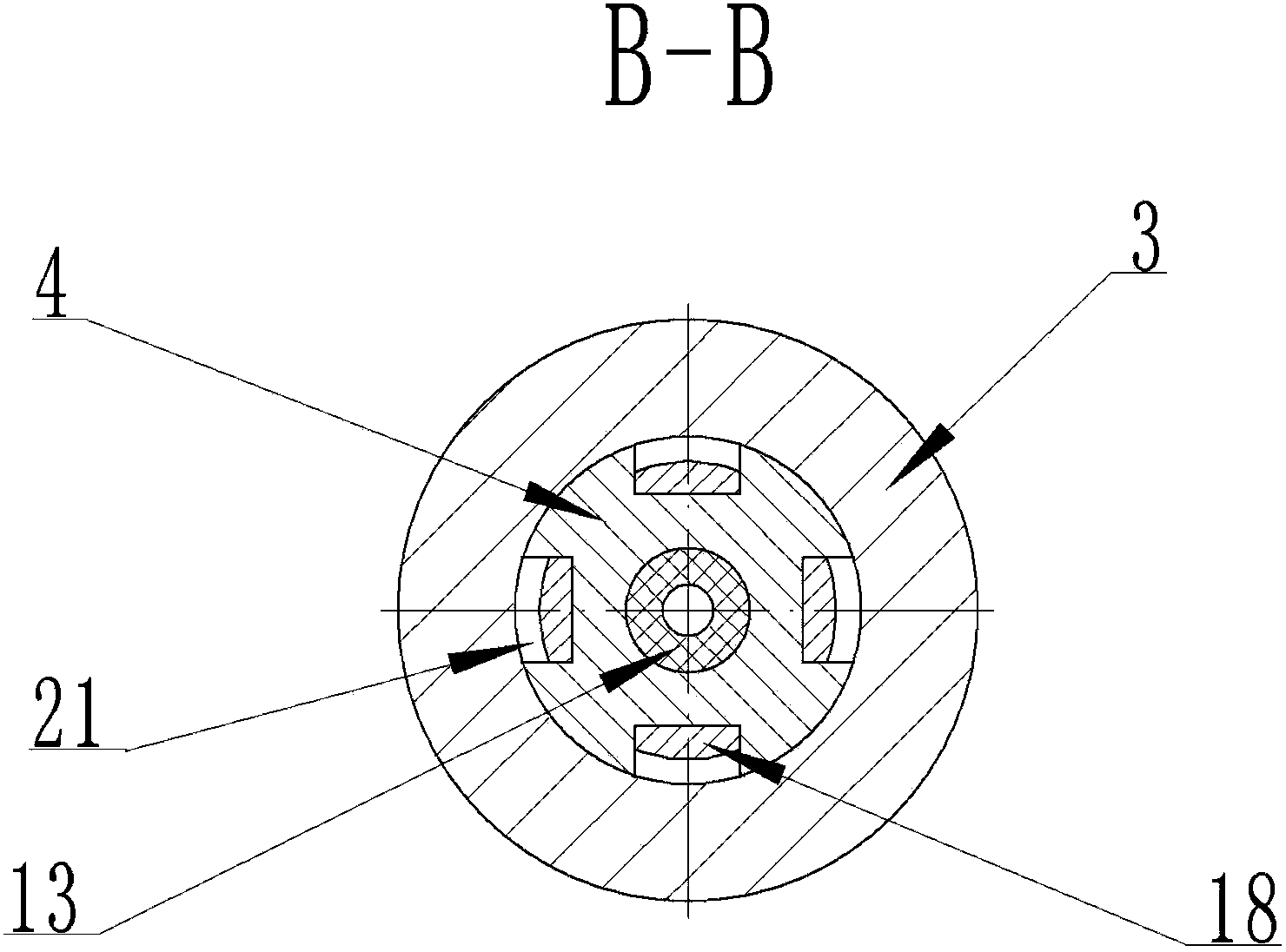

[0014] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0015] A liquid-controlled two-stage well test blowout prevention box includes a lower joint 1, a connecting body 2, a sealing sleeve 3, a sealing box 4, a first-stage piston 5, a second-stage piston 6 and a liquid cylinder 7; the upper end of the lower joint 1 is connected to the The lower end of the connecting body 2 is sealed and connected, and the upper end of the connecting body 2 is sealed and connected with the lower end of the sealing sleeve 3, and the lower joint 1 and the connecting body 2 are both formed with an axial through hole I8; the lower part of the sealing sleeve 3 is formed with a shaft To the through hole II10, a cavity 11 is formed on the upper part, the primary sealing packing 12 is located in the axial through hole II10 and the lower end of the axial through hole II10 is installed with a pressure cap I9, and the pressure rod 16 is located at the bottom of the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com