Axial piston machine with housing filled with pressure medium

A technology of axial piston machines and pistons, which is applied to reciprocating piston engines, liquid variable displacement machines, mechanical equipment, etc., and can solve problems such as the speed limit of axial piston machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

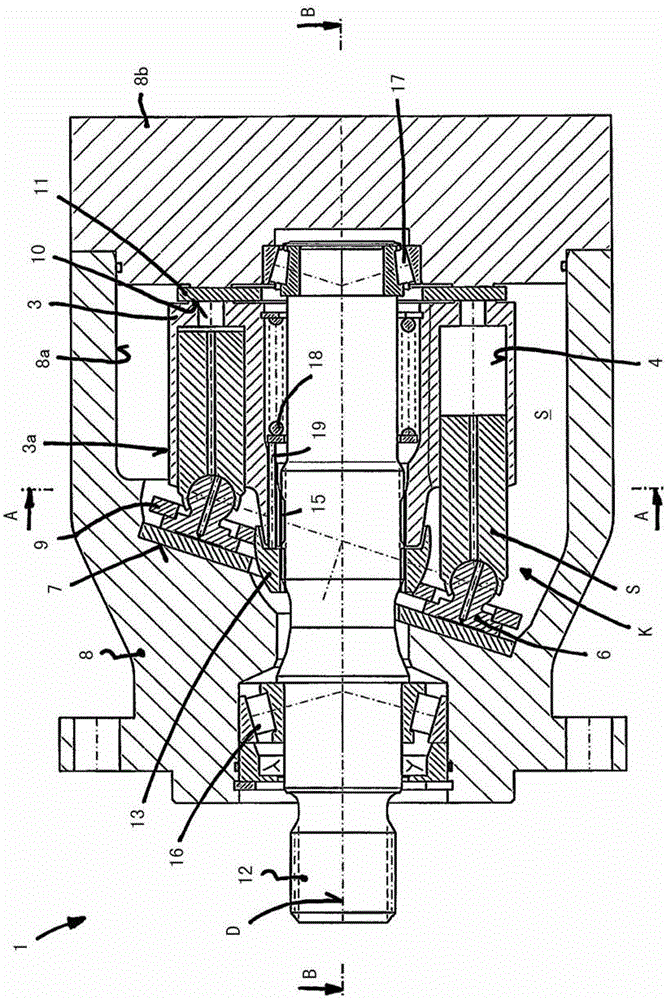

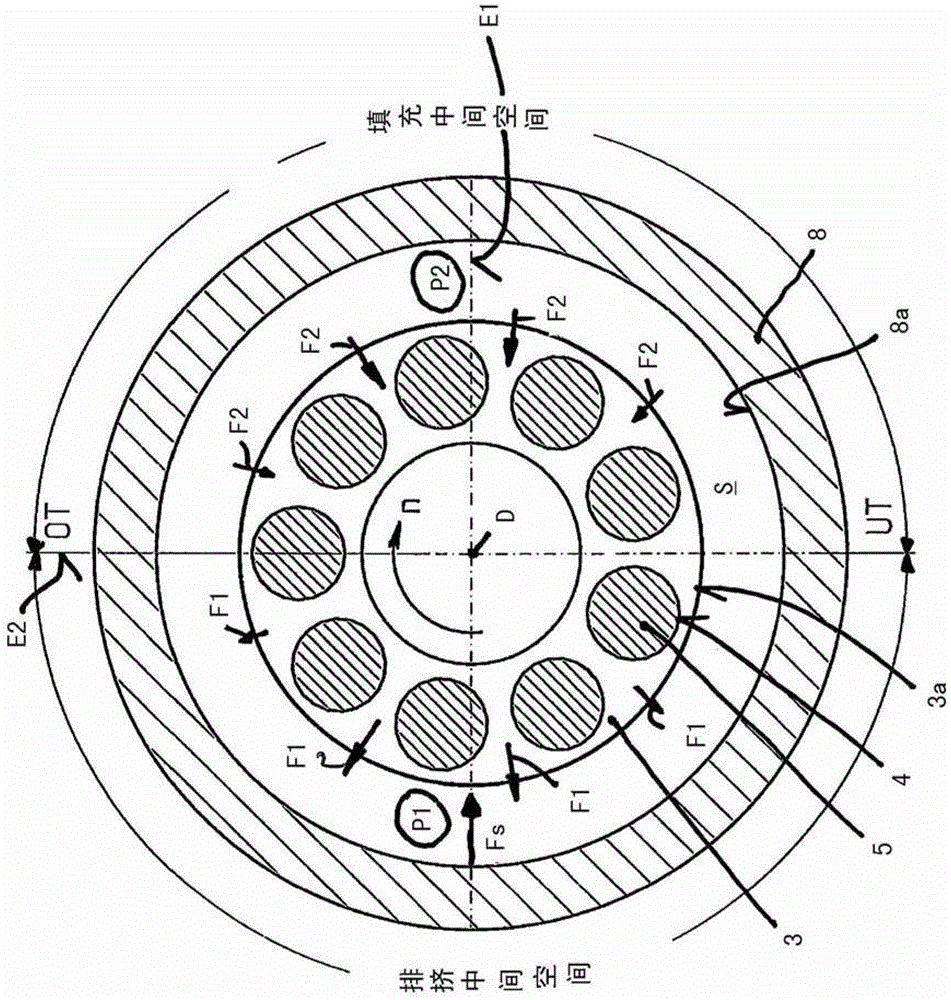

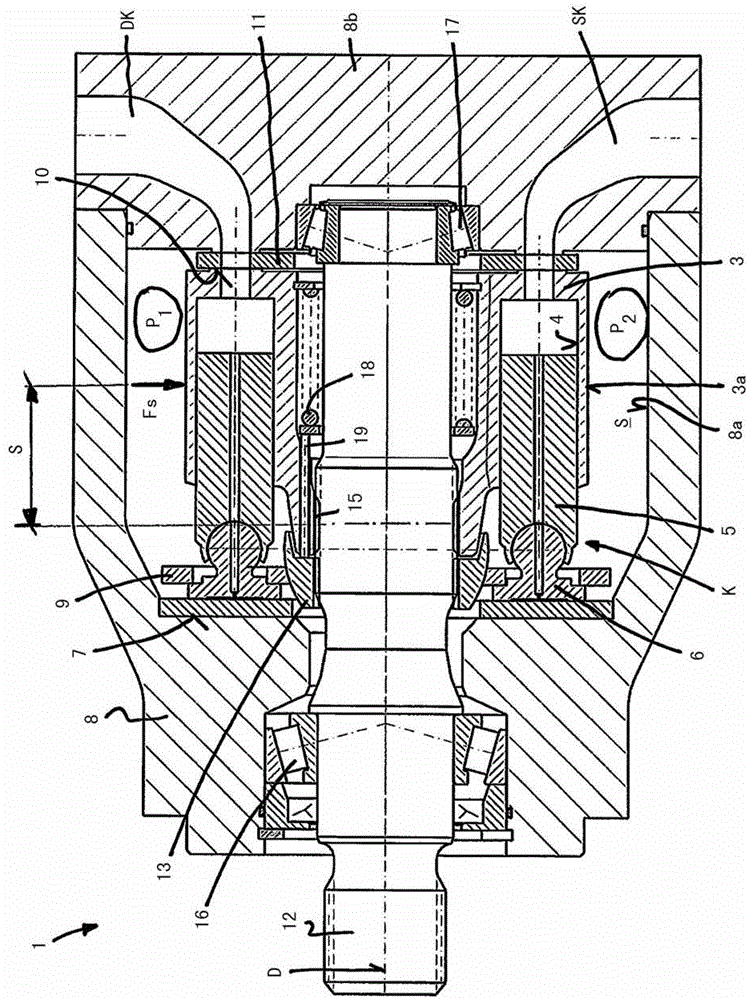

[0031] exist Figures 1 to 3 A prior art hydrostatic axial piston machine 1 of swash plate design is shown in , for example an axial piston pump or an axial piston motor.

[0032] The axial piston machine 1 has a cylinder block 3 arranged rotatably about an axis of rotation D, which is provided with a plurality of piston grooves 4 arranged concentrically with respect to the axis of rotation D, which are preferably formed by cylinders. The bores form and support a piston 5 in each case displaceable in the longitudinal direction in the piston grooves. The cylinder 3 and the piston 5 are the rotary drive components of the axial piston machine 1 .

[0033] The cylinder block 3 is supported in the axial direction on a control surface 10 fixed to the housing, which is formed on a disc-shaped control base 11 fixed in a rotationally fixed manner to the housing 8 or corresponding housing cover 8b. The control bottom 11 is provided with kidney-shaped control slots forming an inlet co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com