Grouting pump safety valve

A safety valve and grouting pump technology, which is applied to pump components, variable displacement pump components, components of a pumping device for elastic fluids, etc., can solve problems such as failure of the safety valve to open in time, potential safety hazards, and blockages. Achieve the effect of increasing the pitch, removing the blockage of the valve port, and expanding the diameter of the valve port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

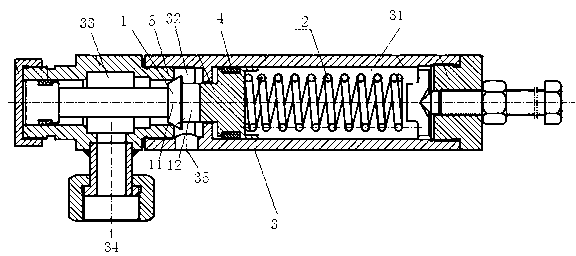

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0009] The safety valve of the grouting pump includes a valve core 1, a spring 2 and a valve body 3. The valve body is provided with a spring chamber 31, a valve core chamber 32 and a pressure chamber 33 connected in sequence. The spring 2 is placed in the spring chamber 31, and the valve core 1 is placed in the spool chamber 32, the spool 1 includes a frustum body 11 and a cylinder 12 fixedly connected coaxially, the frustum body is provided with a large end surface and a small end surface with unequal diameters, the large end surface is fixedly connected with the cylinder body and The large end surface is larger than the cross section of the cylinder. One end of the cylinder of the valve core 1 is inserted into the corresponding end of the spring chamber 31 and elastically connected to the spring. A sealing ring 4 is provided at the insertion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com