CAD (Computer-Aided Design) aided design method of controllable diffused blade profile with curvature continuity

A curvature-continuous, design-aided technology, which is applied to components of pumping devices for elastic fluids, mechanical equipment, non-variable-capacity pumps, etc., can solve problems such as the selection method of Bezier curve control points for which no design parameters are disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

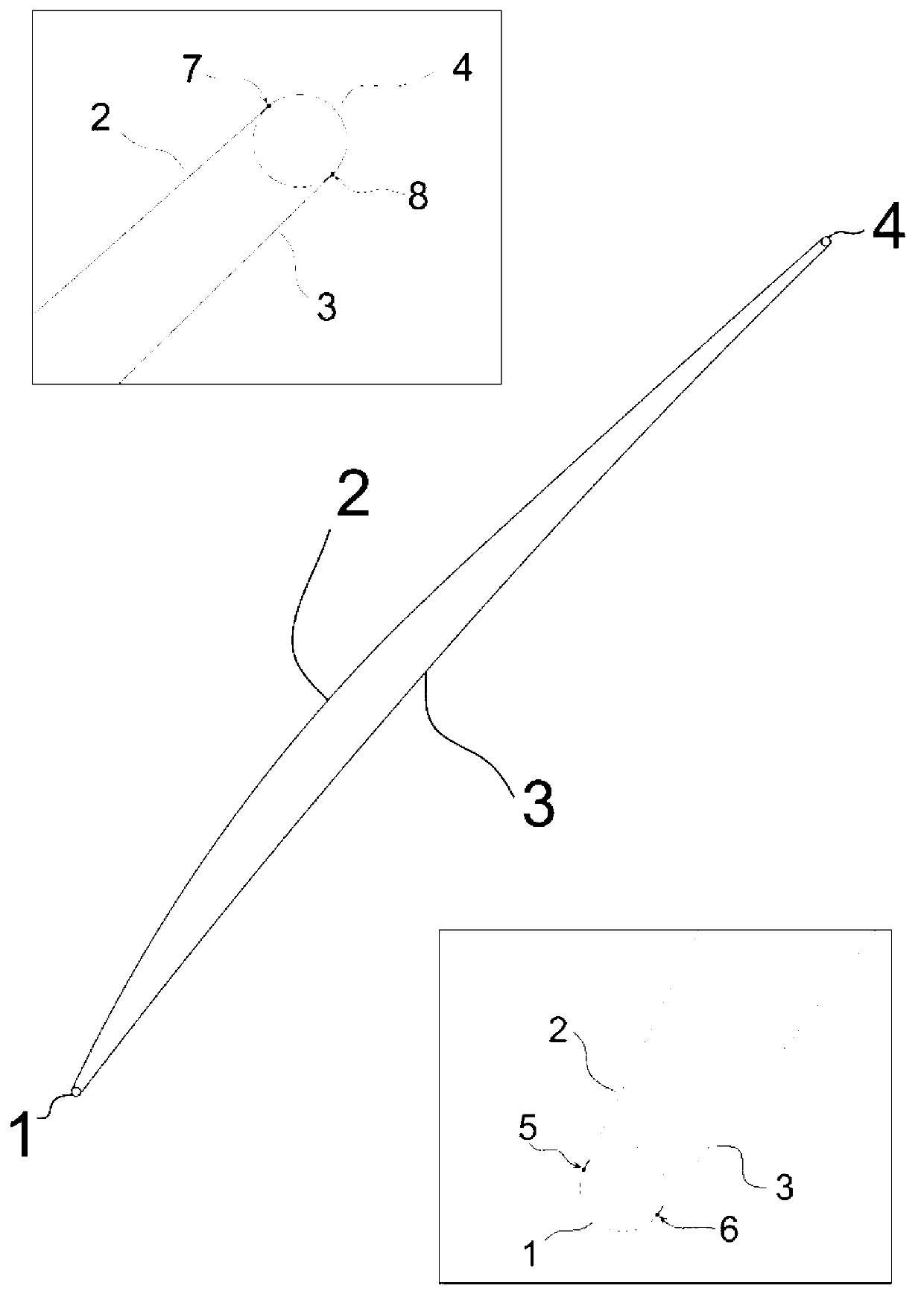

[0092] Thinking of the present invention is as follows:

[0093] 1. Calculate the leading edge point according to the tangent point between the suction surface and the small leading edge circle, and the tangent point between the pressure surface and the small leading edge circle,

[0094] 2. Carry out cubic spline fitting on the suction surface and the pressure surface, and calculate the slope of the curve at each type of value point,

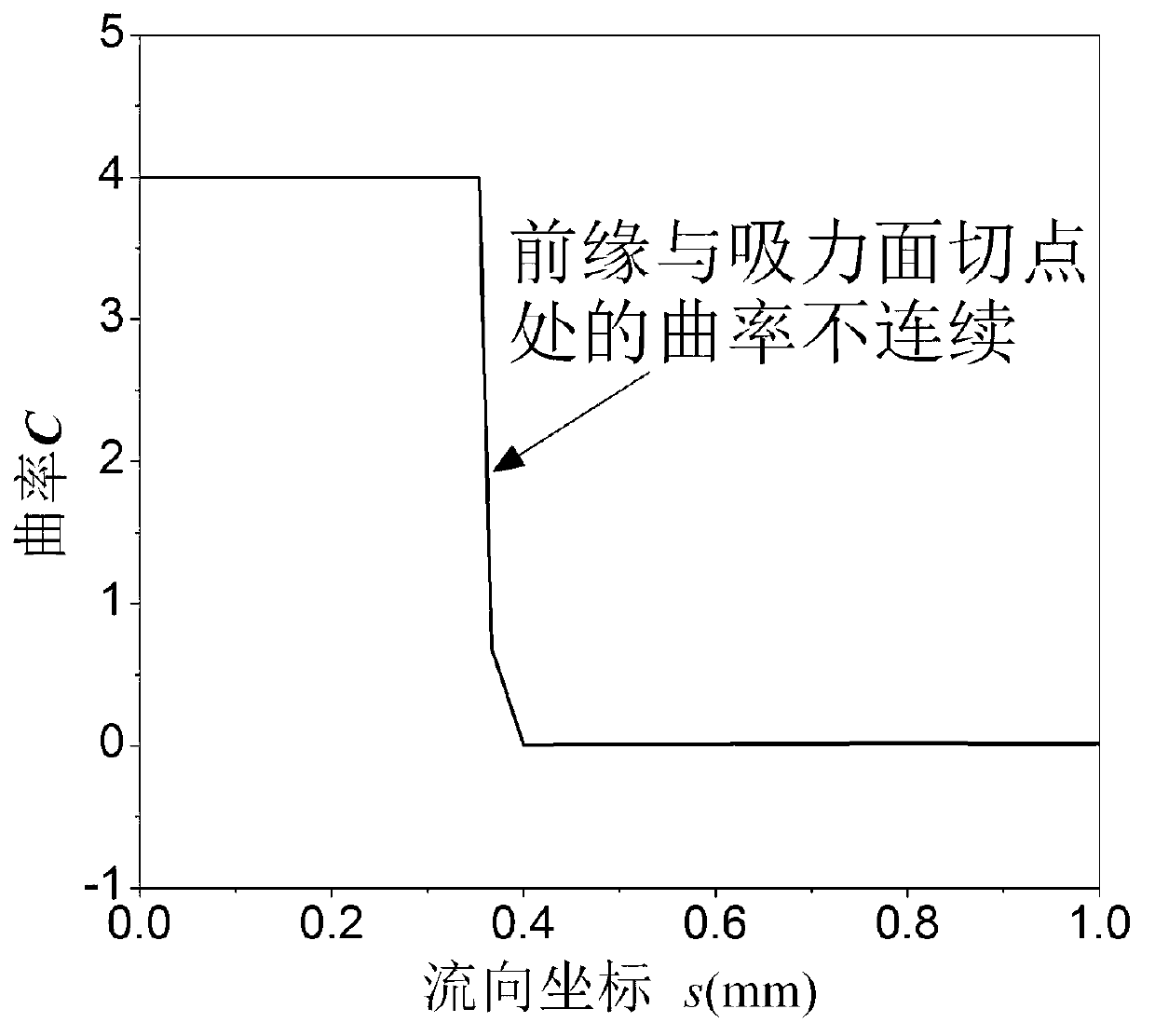

[0095] 3. Use the cubic Bezier curve to give the continuous curvature of the leading edge suction side profile line and the leading edge pressure side profile line, and its control points are obtained by the given initial value selection and iterative method,

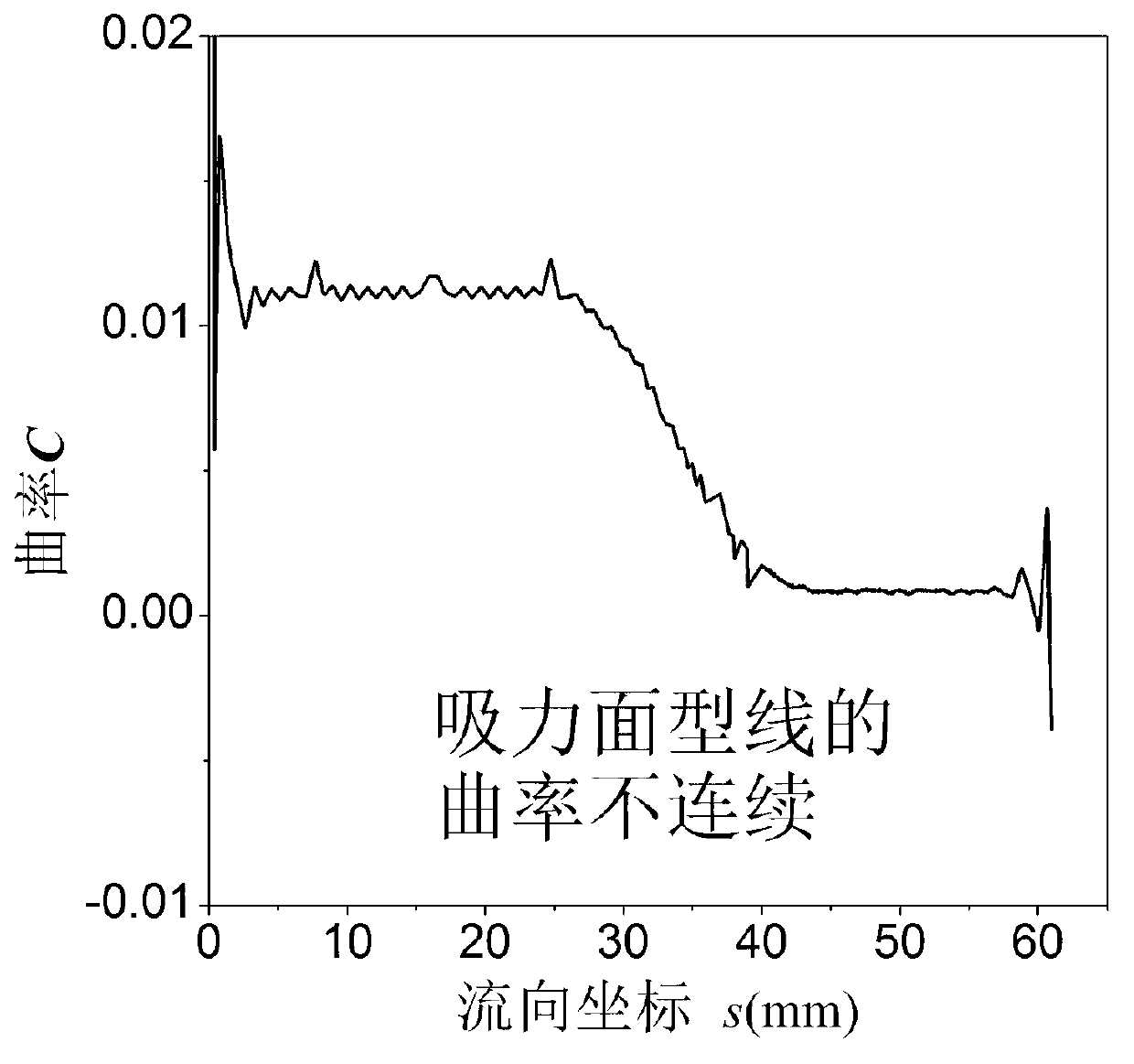

[0096] 5. Use the B-spline curve to give the curvature distribution of the suction surface, and find the control points of the B-spline curve, so that the curvature continuous suction surface corresponding to the curvature distribution curve has the smallest deviation from the original s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com