Grease-storing bearing retainer with rectangular R pockets

A bearing cage, rectangular technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the constraints of high speed, high precision, high-efficiency production of machinery and equipment, affect the stability and rotation accuracy of bearings, and large circumferential clearance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

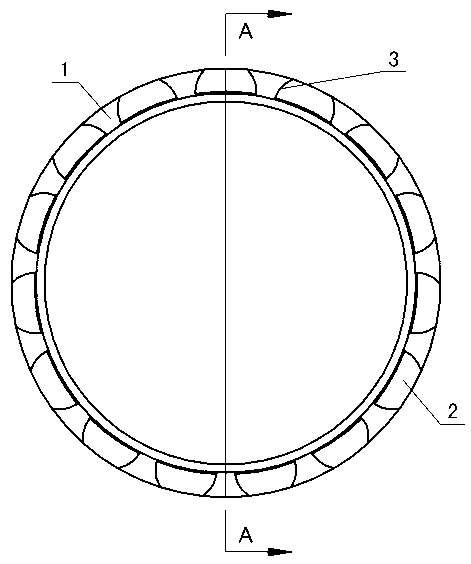

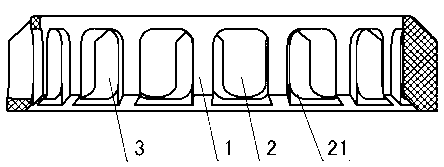

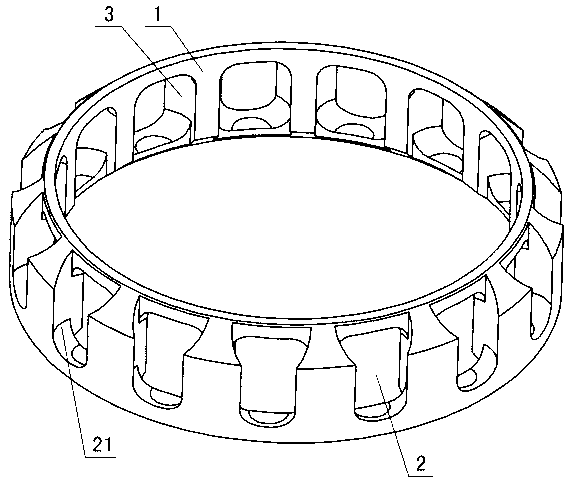

[0010] The invention relates to a rectangular R pocket grease storage type bearing cage, such as figure 1 — Figure 4 As shown, the cage 1 is made with a ball hole, which is characterized in that the ball hole is a rectangular R pocket 2, and the rectangular R pocket is a circular corner 21, and a dimple 3 is formed on the hole wall of the rectangular R pocket , Dimple 3 is in contact with ball 5 . It is mainly to improve the design of the structure of the ball hole of the cage 1. The ball hole of the existing cage is a round hole. The round hole and the round ball have a small space for cooperation. Now it is changed to a rectangular R pocket 2. The rectangular That is, the main body of the bearing hole is a rectangular hole, and the R pocket, that is, the corner of the rectangle is an R arc corner, and the rectangular R pocket 2 is exactly the bearing hole of the rectangular R arc corner, 1. The rectangle reduces the circumferential gap by 70 %, increase the axial floating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com