Framework-free conveniently installed electric heating floor system

An electric heating floor, no keel technology, applied in the field of building decoration materials, can solve the problems of reducing the use intensity of the heating floor, difficult disassembly and maintenance of the heating floor, increasing the consumables of the heating floor, etc., to achieve convenient follow-up maintenance, high-efficiency heating effect, and strong adaptability effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

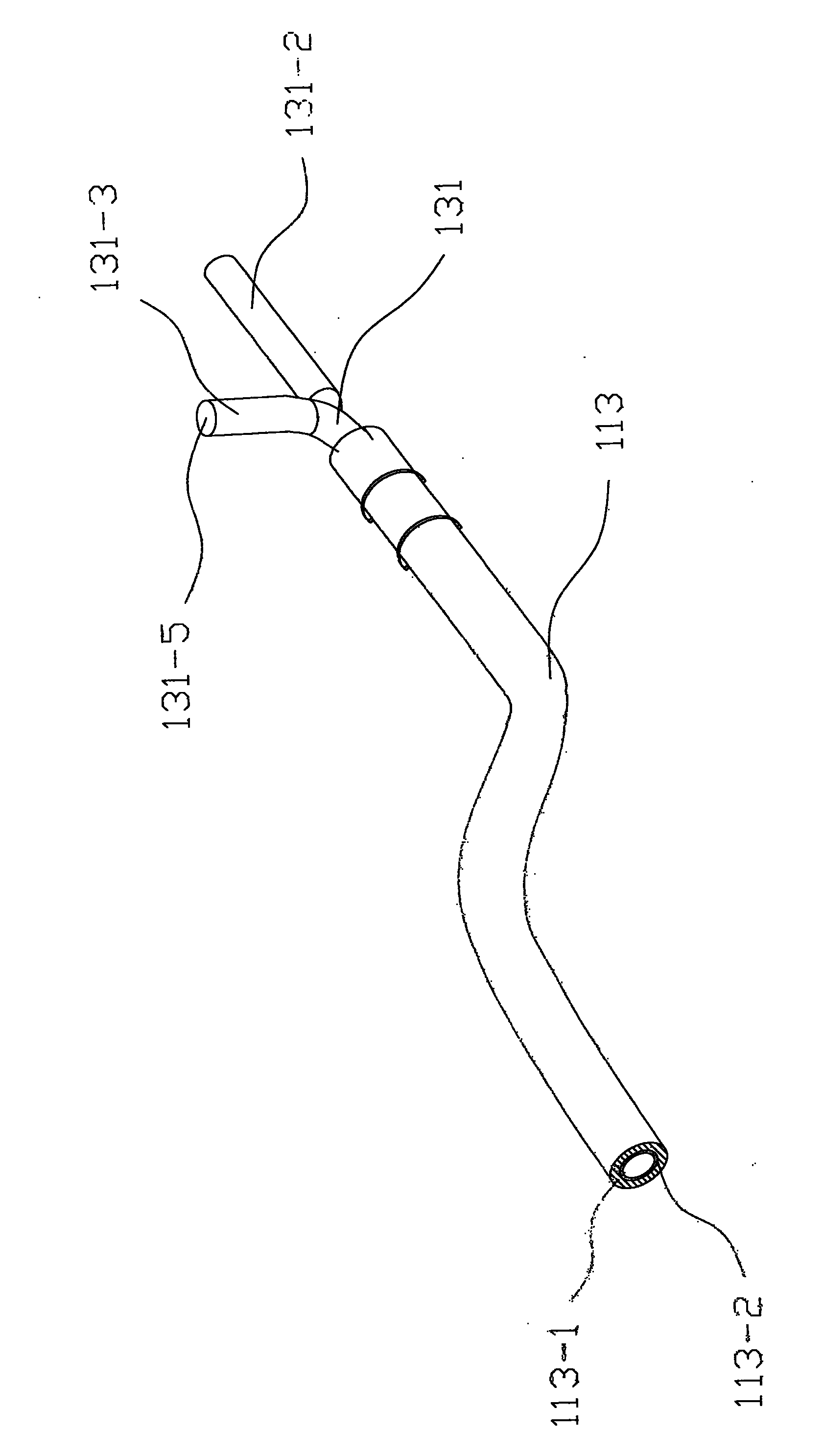

[0165] Implementation Case 1 An electric heating floor with a screw-type conductive connection device

[0166] Such as Figure 11 Shown is an embodiment of the present invention, a kind of electric heating floor with connecting device 10-11, and this connecting device is fixed in the corresponding groove of electric heating floor by screw, two bottom heat preservation boards of each electric heating floor There are two grooves on each of the short edges, and the size of the grooves can be adjusted accordingly according to the size of the electric heating floor. In the figure, there are two connecting devices on one short edge of the bottom insulation board of the electric heating floor, and the other short The two connecting devices on the edge are omitted. There are four screw holes with the same diameter on each connecting device. The screws are screwed into the screw holes of the connecting device and screwed into the electric heating floor, so as to be firmly fixed in the...

Embodiment example 2

[0190] Implementation Case 2 Another electric heating floor with a screw-fixed conductive connection device

[0191] Such as Figure 30 Shown is another electric heating floor with a screw-fixed conductive connection device of the present invention, the connecting device is fixed in the corresponding groove of the electric heating floor by screws, and the two short edges of the bottom insulation board of each electric heating floor There is a groove at each place, and the size of the groove can be adjusted accordingly according to the size of the electric heating floor. In the figure, a connecting device is drawn on one short edge of the bottom insulation board of the electric heating floor, and a connecting device is drawn on the other short edge. The connecting device is omitted. There are four screw holes with the same diameter on each connecting device. The screws are screwed into the screw holes of the connecting device and screwed into the electric heating floor, so as ...

Embodiment example 3

[0201] Implementation Case 3 An electric heating floor with a slot-fixed conductive connection device

[0202] Such as Figure 36 Shown is a three-dimensional schematic diagram of an electric heating floor with a slot-fixed conductive connection device according to the present invention. The connection device is fixed in the corresponding groove of the electric heating floor through a slot. There are two grooves on the edges of each short side, and the size of the grooves can be adjusted accordingly according to the size of the electric heating floor. There are two connecting devices on one short edge of the bottom insulation board of the electric heating floor in this figure. The two connection devices on the edge of the other short side are omitted. Each connection device is pushed into the groove through the card slot installation form, so that the connection device is firmly fixed in the electric heating floor. This installation method is convenient and fast, and it is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com