Air conditioning compressor exhaust energy recovery and utilization method

An air-conditioning compressor, compressor technology, applied in the direction of compressors, ventilation and heating energy recovery systems, irreversible cycle compressors, etc., to achieve the effect of improving refrigeration or heating capacity and improving air conditioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

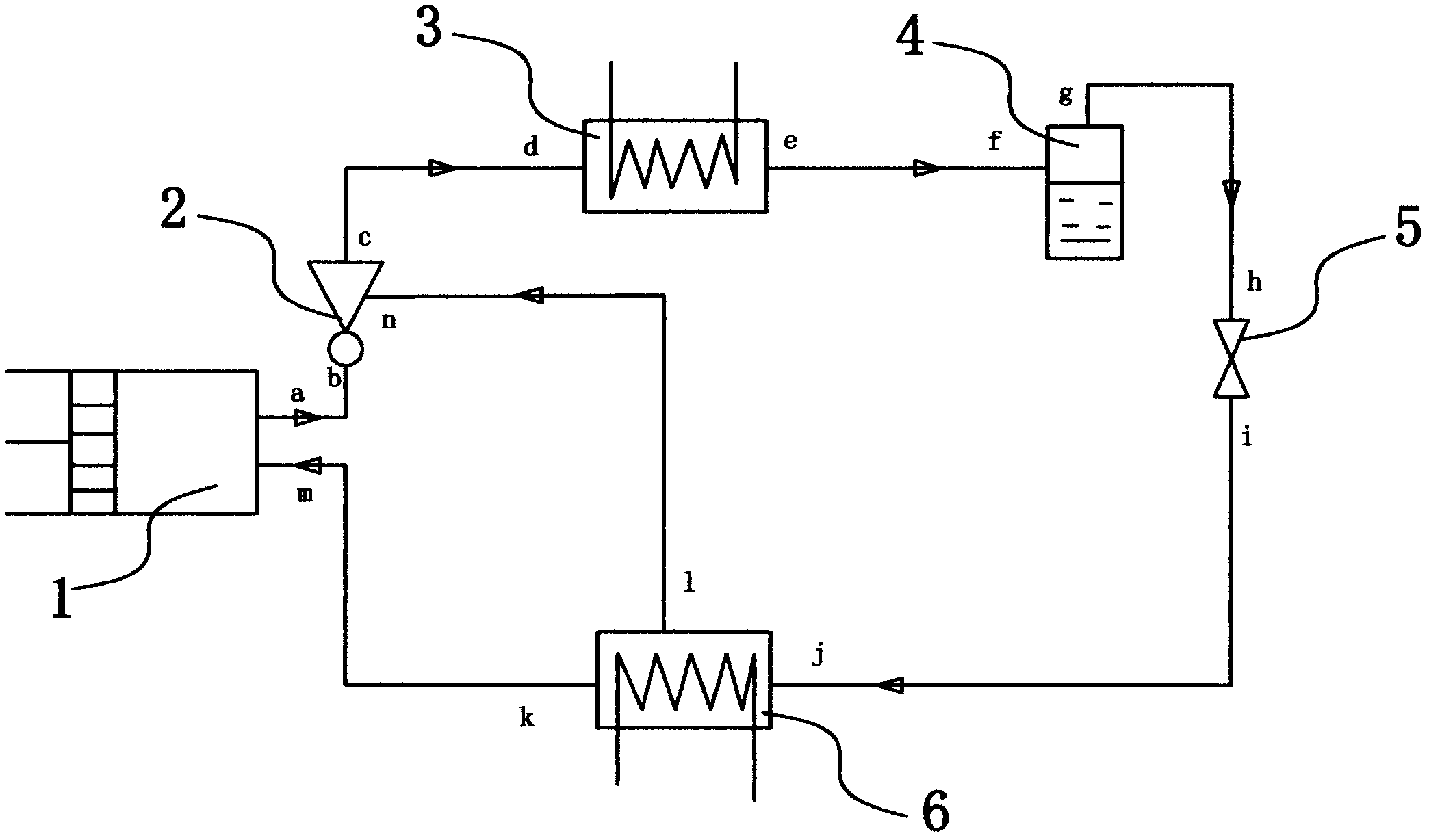

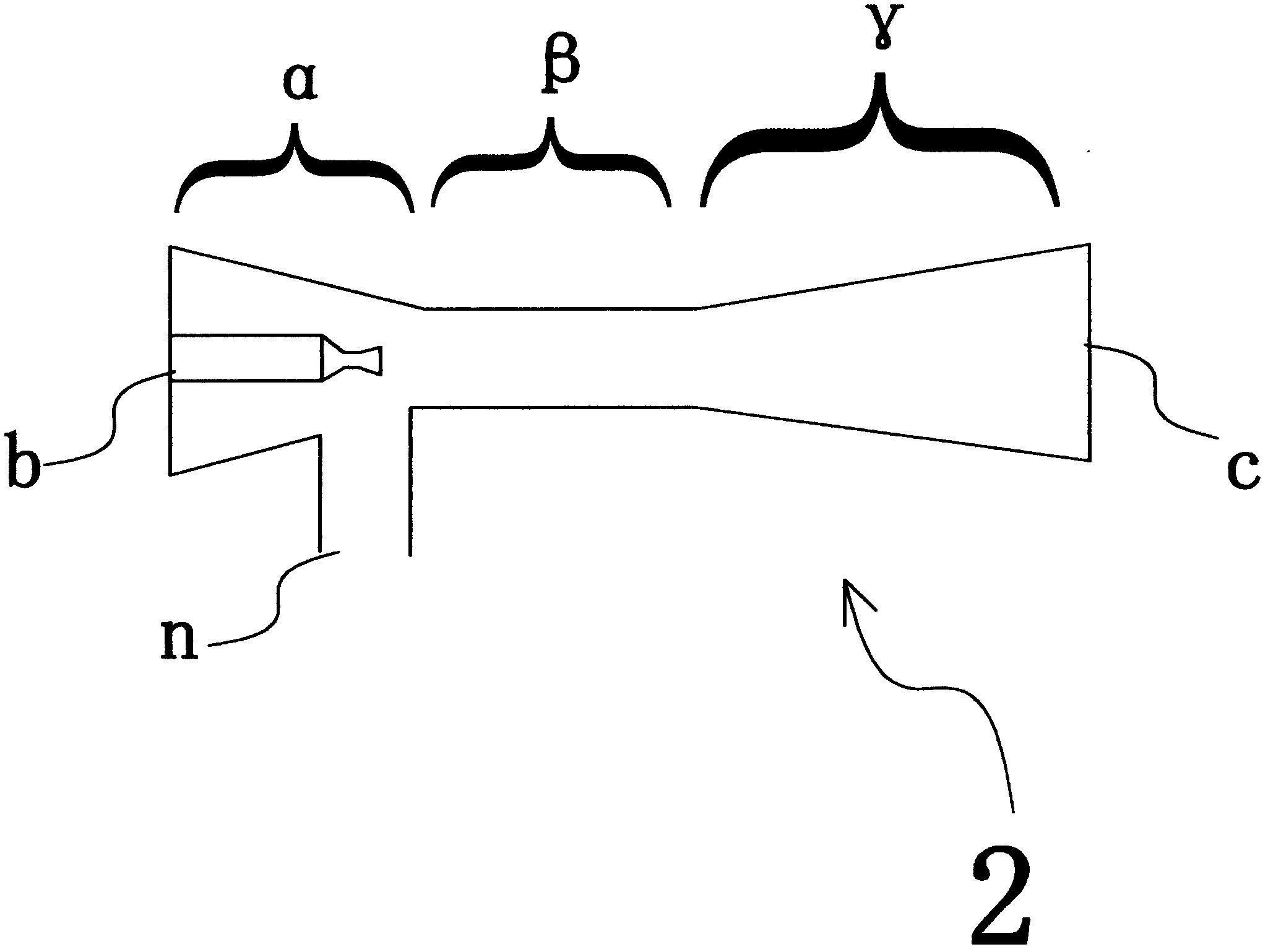

[0027] Such as figure 1 As shown, the outlet a of the compressor 1 in the figure and the ejector 2 ( figure 2 It is the structural diagram of the injector, which includes the introduction section α, the mixing section β and the diffusion and boosting section γ. The left side of the figure is the inlet b of the injector, which is the inlet port of the working fluid; the right side is the outlet c of the injector , which is used as the outlet port of the mixed fluid; the lower side is the diversion inlet n of the injector, which is used as the inlet port of the introduced fluid) and the inlet b is connected, so that the high-pressure and high-temperature medium fluid at the outlet a of the compressor becomes the working fluid of the injector, Enter the ejector from the inlet b; connect the outlet c of the ejector 2 to the inlet d of the condenser 3 of the air conditioning system, so that the working fluid and the injection fluid are mixed, diffused and pressurized and then ente...

Embodiment 2

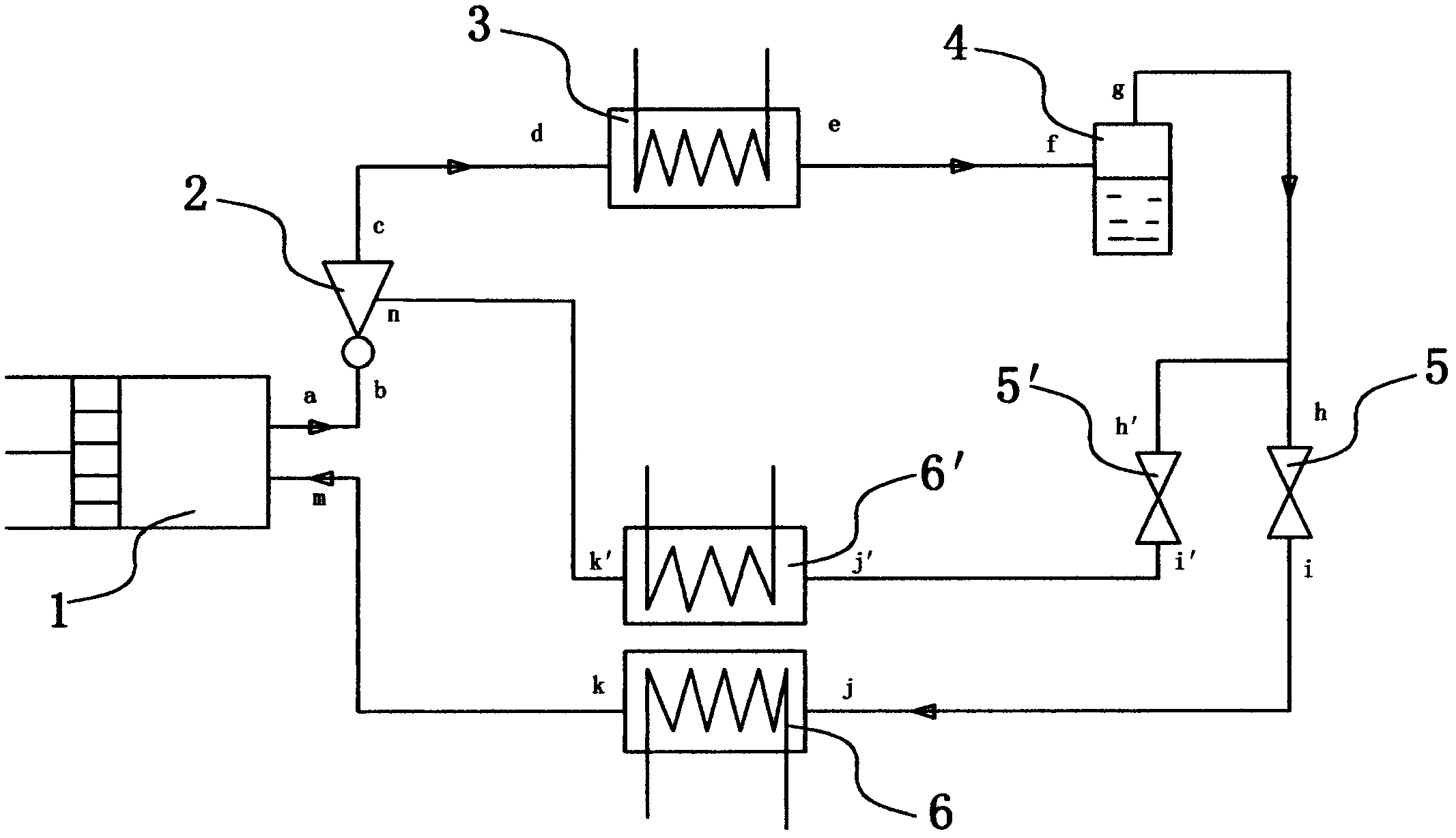

[0030] see image 3 , connecting the outlet a of the compressor 1 in the figure with the ejector 2 ( figure 2 Inlet b of the injector structure diagram) is connected, so that the high-pressure and high-temperature medium at the outlet a of the compressor becomes the working fluid of the injector, and enters the injector from the inlet b of the injector; the outlet c of the injector 2 is connected with the air-conditioning system The inlet d of the condenser 3 is connected so that the working fluid and the injection fluid are mixed, diffused and pressurized and then enter the condenser 3 from the inlet d of the condenser; the outlet e of the condenser 3 is connected with the inlet f of the air-water separator 4 of the air conditioning system Connected, the filtered medium flow comes out from the outlet g of the gas-water separator and enters the inlet h of the throttle valve 5 and the inlet h' of the throttle valve 5' of the air-conditioning system respectively, and the thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com