Refrigerator

A technology of refrigerators and refrigerants, applied in household refrigerators, household refrigeration devices, defrosting, etc., can solve the problems of longer defrosting time, cooler temperature difference, and ineffective melting, etc., and achieve high energy-saving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

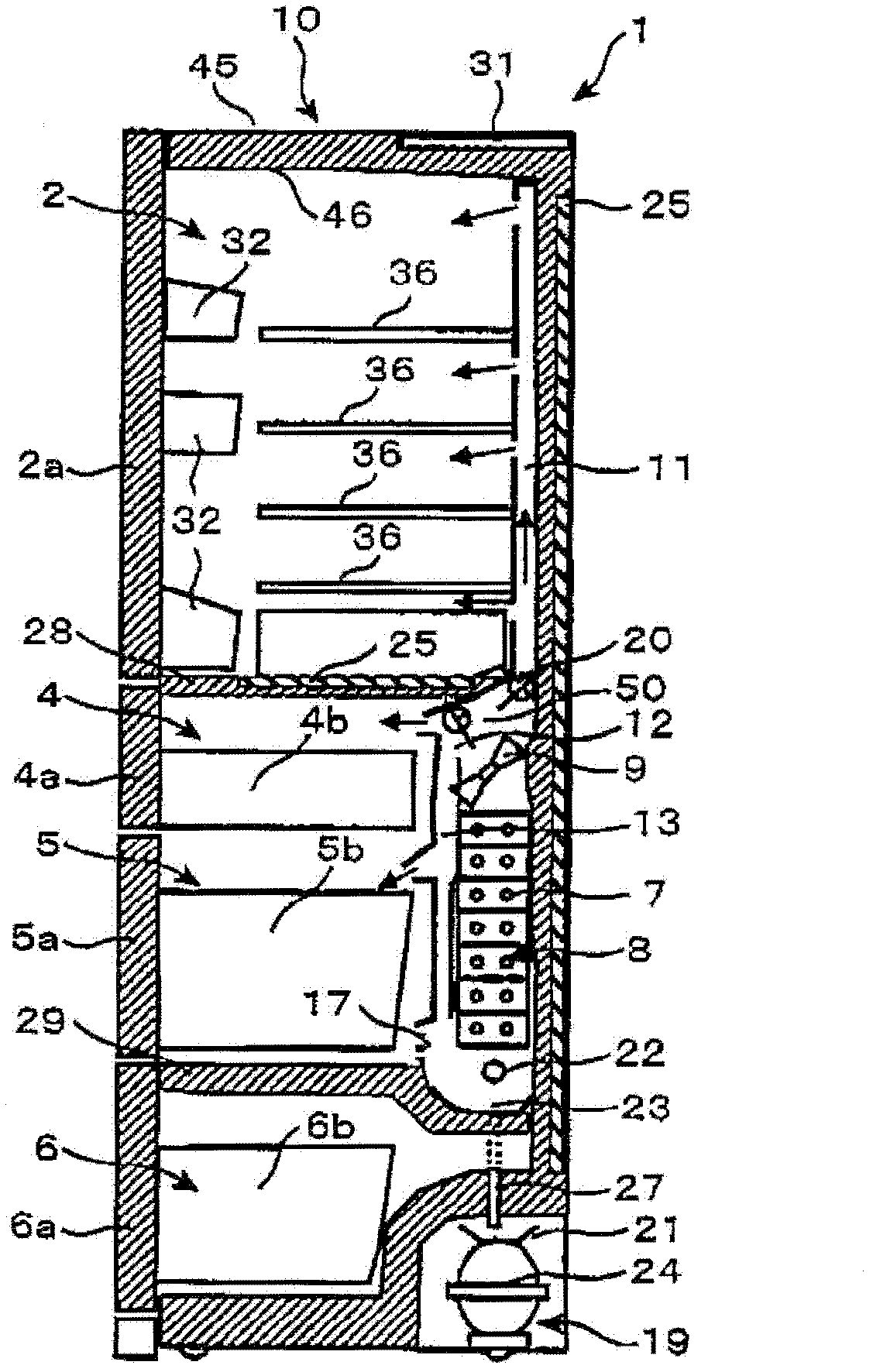

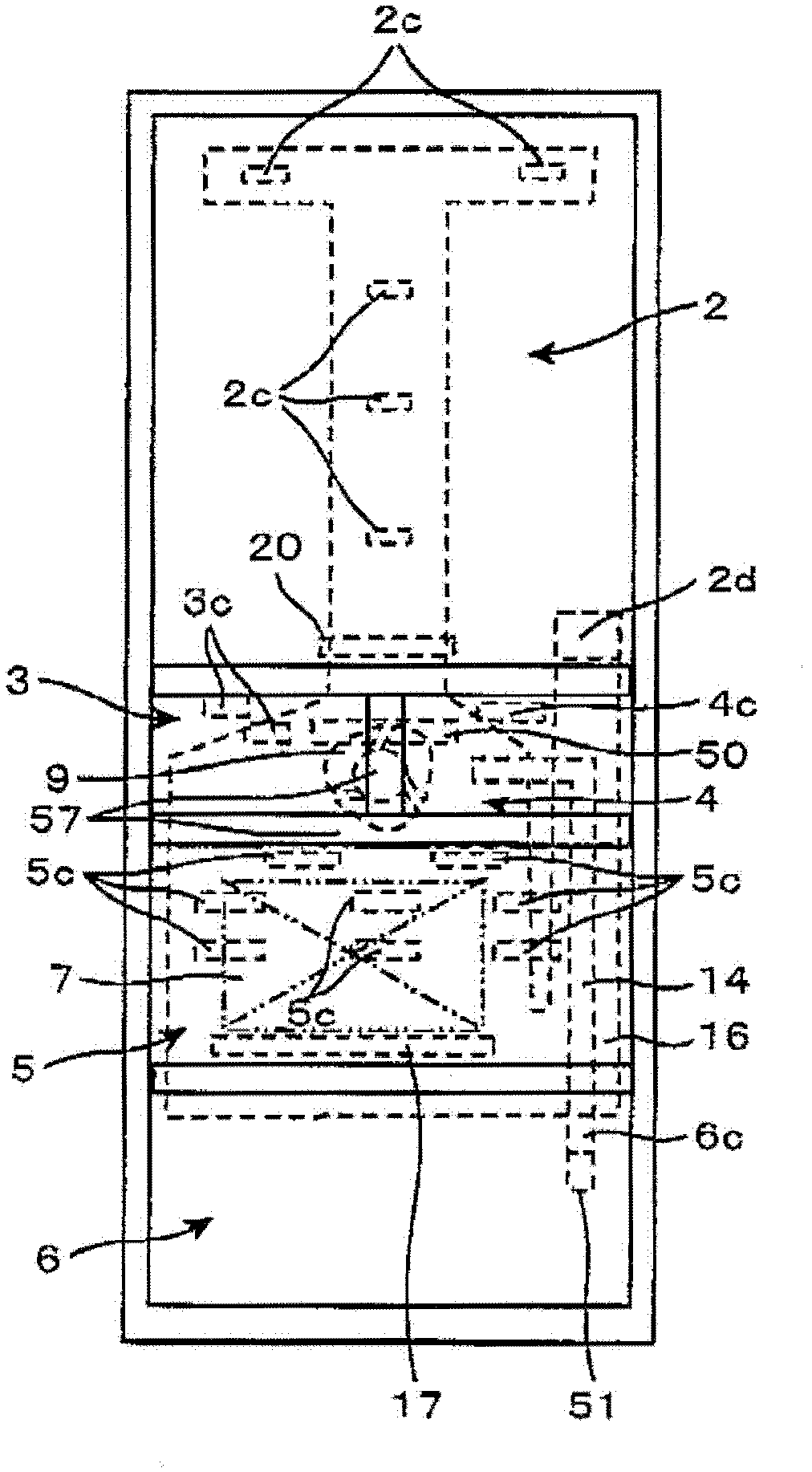

[0069] Second, refer to Image 6 The refrigeration cycle of Example 1 will be described. Image 6 It is a schematic diagram showing the refrigerant flow path of a refrigerator.

[0070] Image 6 Among them, 24 is the compressor for compressing the refrigerant in the refrigeration cycle, which is set at figure 2 In the shown machine chamber 19, the rotational speed is controlled by the control board 31 so that it can be changed. 52 is a condensing mechanism for condensing the refrigerant compressed by the compressor 24 .

[0071] The condensing mechanism 52 is composed of a condenser 52a arranged in the machine room 19 to condense the refrigerant compressed by the compressor 24, a heat radiation pipe 52b which condenses the refrigerant and prevents condensation on the side of the refrigerator 1, and condenses the refrigerant and prevents the partition 57 from condensing. Exposed heat pipe 52c constitutes. Also, the partition 57 for disposing the radiating pipe 52c, such a...

Embodiment 2

[0089] Second, refer to Figure 9 The refrigeration cycle of Example 2 will be described. Figure 9 It is a schematic diagram showing the refrigerant flow path of a refrigerator.

[0090] Indicated at 55 is a connection pipe (second refrigerant flow path) connecting the radiation pipe 52b and the decompression device 58 . Indicated at 54 is a refrigerant valve (first refrigerant flow adjustment mechanism) for blocking or switching the radiation pipe 52c (first refrigerant flow path) and the connecting pipe 55 (second refrigerant flow path). 56 is a check valve provided at the outlet of the refrigerant passage (the outlet of the heat radiation pipe 52c (first refrigerant passage)) to prevent refrigerant from entering between the refrigerant passage of the heat radiation pipe 52c and the connecting pipe 55 . Since other symbols are the same as those in Embodiment 1, the same symbols are assigned and descriptions thereof are omitted.

[0091] The control mechanism at the time ...

Embodiment 3

[0104] Second, refer to Figure 12 The refrigeration cycle of Example 3 will be described.

[0105] exist Figure 12 Among them, 54a is a refrigerant valve (the first refrigerant flow path adjustment mechanism) that blocks or switches the radiating pipe 52c and the connecting pipe 55, and 54b is a refrigerant valve that blocks the refrigerant flow path to the decompression device 58 (second refrigerant flow path adjustment mechanism). agent channel adjustment mechanism), the decompression device 58 decompresses the refrigerant condensed by the condensing mechanism. The other symbols are the same as those in Example 1, and description thereof will be omitted.

[0106] The control mechanism at the time of defrosting in the third embodiment will be described. Figure 13 It is a timing chart showing the states of the compressor, the defrosting heater, the first refrigerant flow path adjustment mechanism, and the second refrigerant flow path adjustment mechanism during defrostin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com