Intelligent sliding pressure curve design method for thermal power units based on coordinated control quality

A sliding pressure curve and coordinated control technology, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., to achieve the effects of reducing fluctuation range, enhancing stability, and ensuring energy-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific implementations of the specification.

[0020] 1. The shape of the smart sliding curve

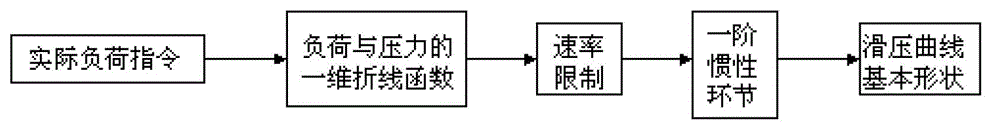

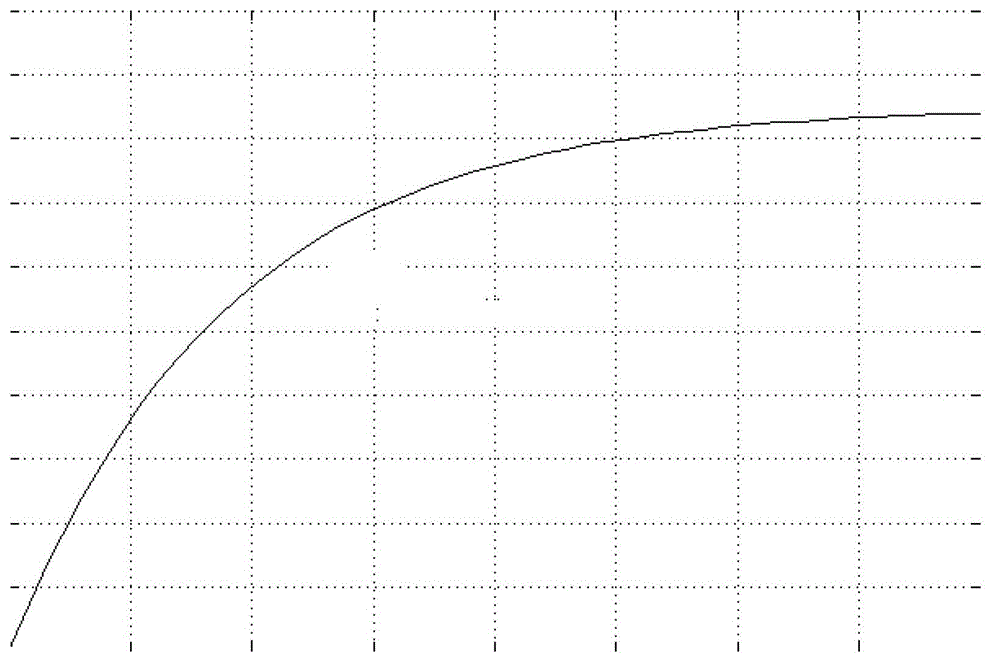

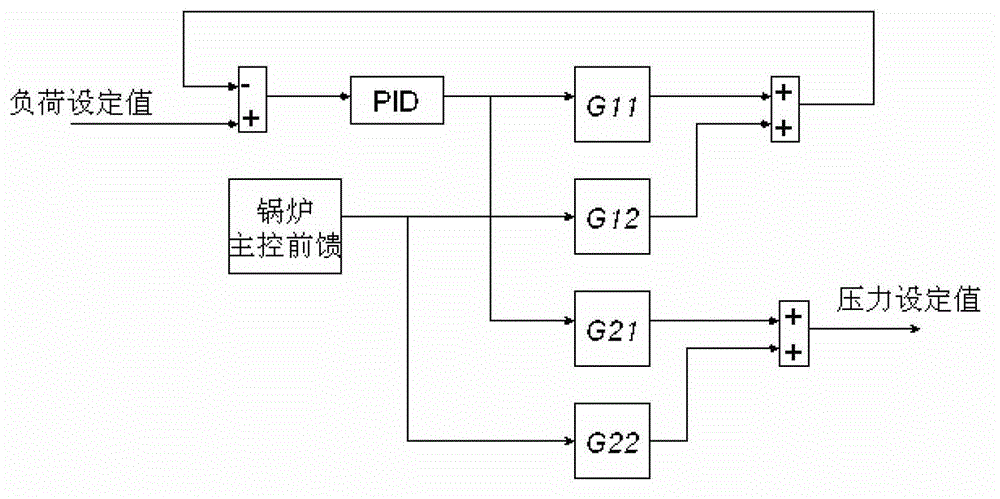

[0021] The principle of generating the basic shape of the sliding pressure curve is as follows figure 1 As shown, it is the basic shape of the sliding pressure curve formed by converting the actual load command into a pressure command through a one-dimensional broken line function, and then passing through the rate limit and the first-order inertia link, such as figure 2 As shown, this curve is used as a pressure setpoint command in conventional control logic.

[0022] In the automatic regulation of thermal engineering, the index of coordinated control is to control the dynamic deviation of load within 3% of the maximum load and the dynamic deviation of pressure within ±0.5MPa. However, in the process of dynamic variable load, due to the inertia of the actual pressure, it is difficult to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com