Roller table of a rolling train

A technology of roller tables and trains, applied in metal rolling, metal rolling, metal processing equipment, etc., to achieve the effects of improving output, increasing stacking density, and reducing electricity bills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

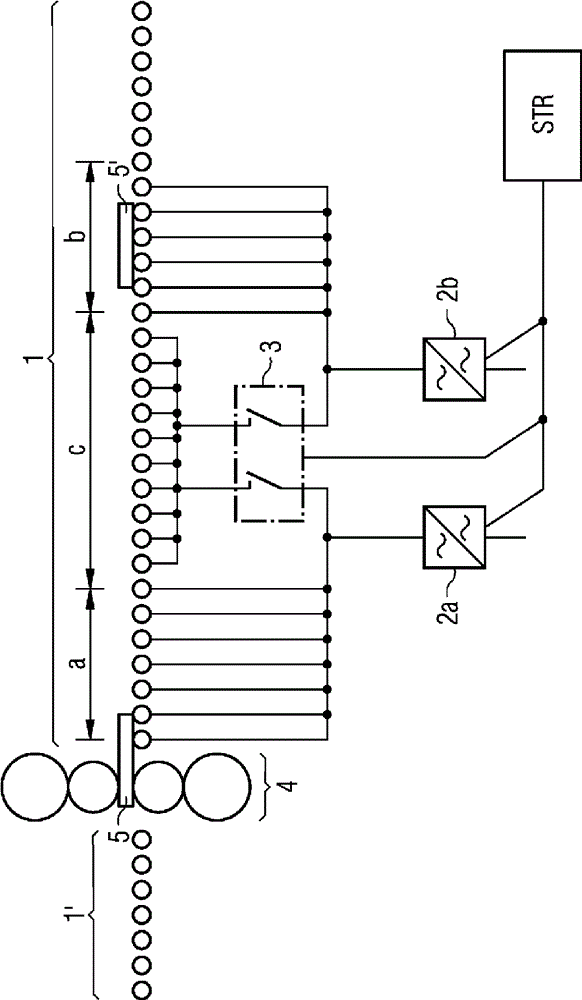

[0016] The illustration includes a rolling stand 4 with roller tables 1, 1' arranged on both sides. The first rolling stock 5 leaves the rolling stand 4 and is transported onward by means of the roller table 1 . On the roller table 1 there is already another rolling stock 5', which has already passed the rolling stand 4 and cooled if necessary.

[0017] For the sake of simplicity, the present invention is only described according to the roller table 1 . Said roller table 1' on the other side of said rolling stand 4 advantageously has the same features.

[0018] The considered roller table 1 has a plurality of rollers. The first roller table section a is fixedly assigned to the first deflector 2 a. The corresponding roller drive is directly connected to the output of the first converter 2a. The second roller table section b is fixedly assigned to the second deflector 2 b. Following the roller table section b, the roller table 1 also has further rollers, the drive supply of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com