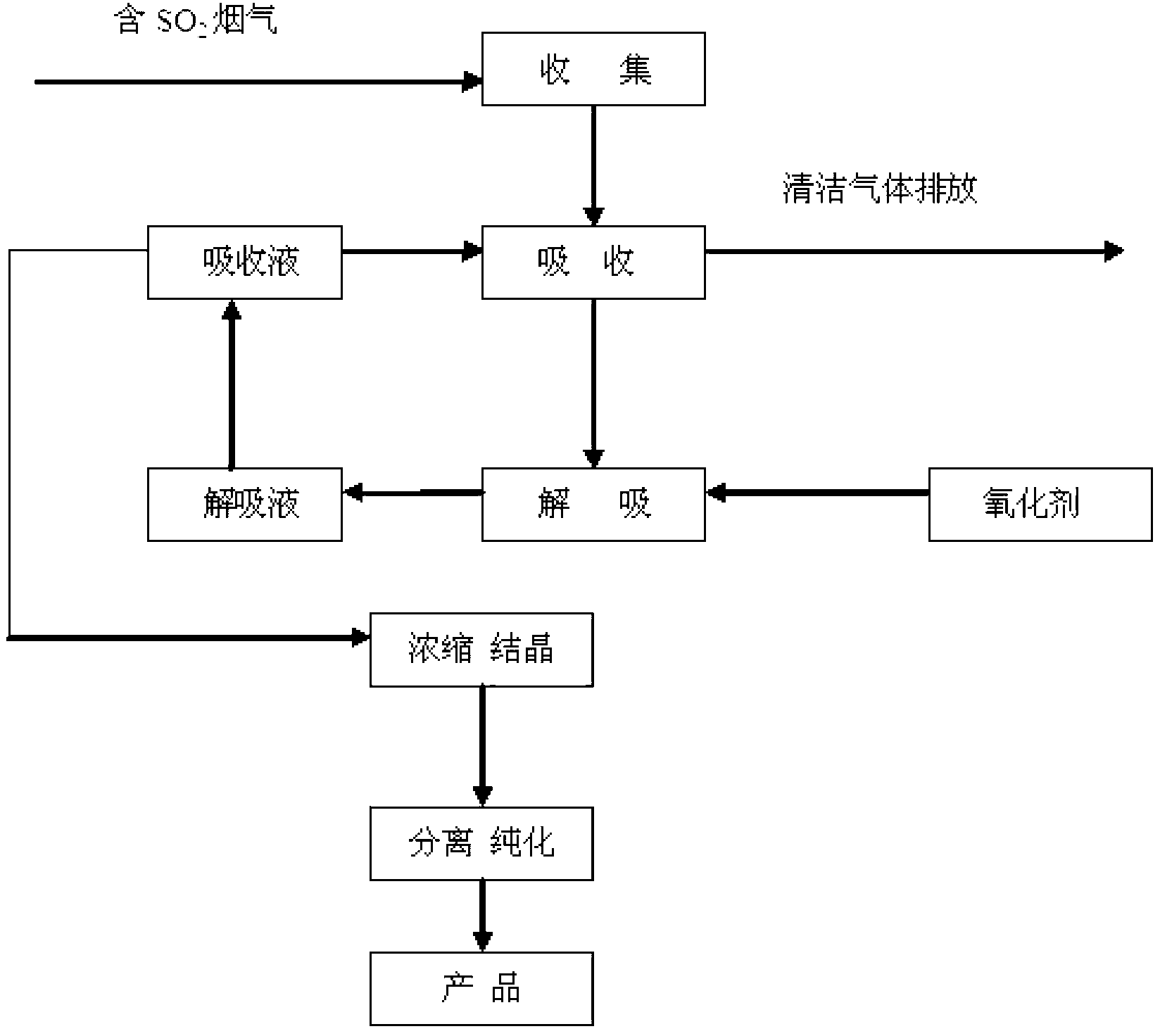

Wet redox, desulfuration and resource utilization method for flue gas

A technology of wet oxidation and recycling, which is applied in chemical instruments and methods, separation methods, and through absorption. It can solve the problems of high investment and operating costs, large water consumption, and large floor space, and achieve huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 125mL of a ferric chloride solution with a hydrogen ion concentration of 1mol / L and a ferric iron concentration of 2.0mol / L, and pass sulfur dioxide into it at 30°C and 1 atm. The input amount is 0.125mol, and the reaction time is 0 -1.5h, the absorption liquid becomes shallow. The test result is: hydrogen ion concentration=1.56mol / L, Fe 2+ =1.47mol / L, and the sulfate concentration is 0.81mol / L.

[0028] Excessive oxygen is introduced into the solution produced after absorbing sulfur dioxide, so that the divalent iron in the solution becomes trivalent iron, and the obtained trivalent iron solution is recycled for absorbing sulfur dioxide.

[0029] Repeat the foregoing operations and after three cycles, the obtained high-concentration sulfate solution is concentrated, separated and crystallized to obtain 63.5 g of iron sulfate product containing crystal water. The mother liquor after crystallization is a mixture of sulfuric acid and hydrochloric acid, and iron oxide or ...

Embodiment 2

[0031] Take 250 mL of a ferric chloride solution with a hydrogen ion concentration of 0.64 mol / L and a ferric iron concentration of 1.0 mol / L, and pass sulfur dioxide into it at 30°C and 1 atmosphere. The input amount is 0.125 mol, and the reaction time is 0-1.5h, the absorption liquid becomes shallow. The test result is: hydrogen ion concentration=1.07mol / L, Fe 2+ =0.86mol / L, the sulfate concentration is 0.45mol / L.

[0032] Excess oxygen is passed into the solution produced after absorbing sulfur dioxide, so that the divalent iron in the solution becomes trivalent iron, and the obtained trivalent iron solution is recycled for absorbing sulfur dioxide.

[0033] Repeat the foregoing operation, after three cycles, the obtained high-concentration sulfate solution is concentrated, separated and crystallized to obtain 59.2 g of iron sulfate product containing crystal water. The mother liquor after crystallization is a mixture of sulfuric acid and hydrochloric acid, and iron oxide or hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com