Comma scraper coating machine capable of automatically adjusting interval

A comma scraper and automatic adjustment technology, applied in the field of coating machines, can solve problems such as gap adjustment accuracy, low repeat positioning accuracy, inability to adapt to the development requirements of high-precision coating machines, and no real-time feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

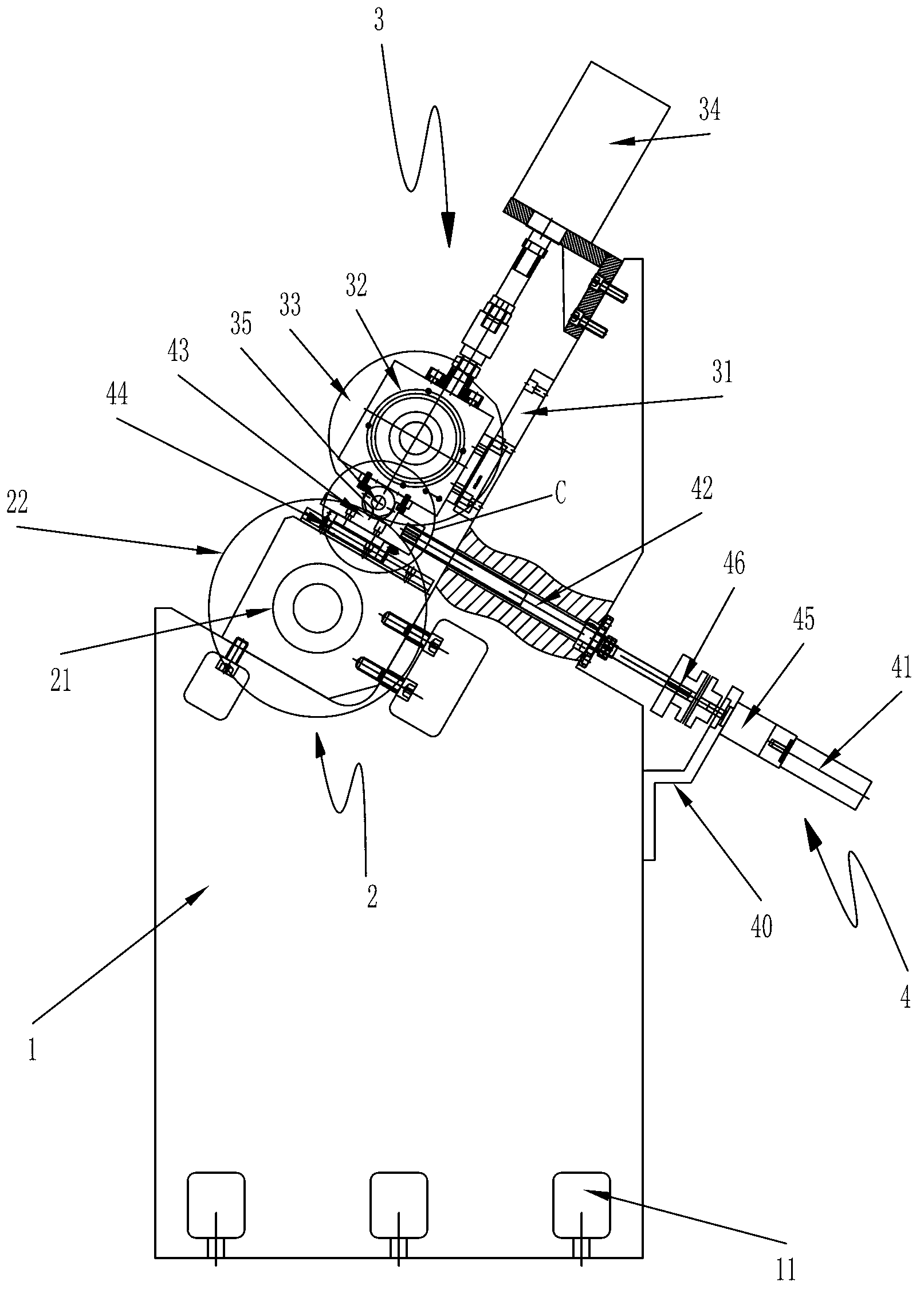

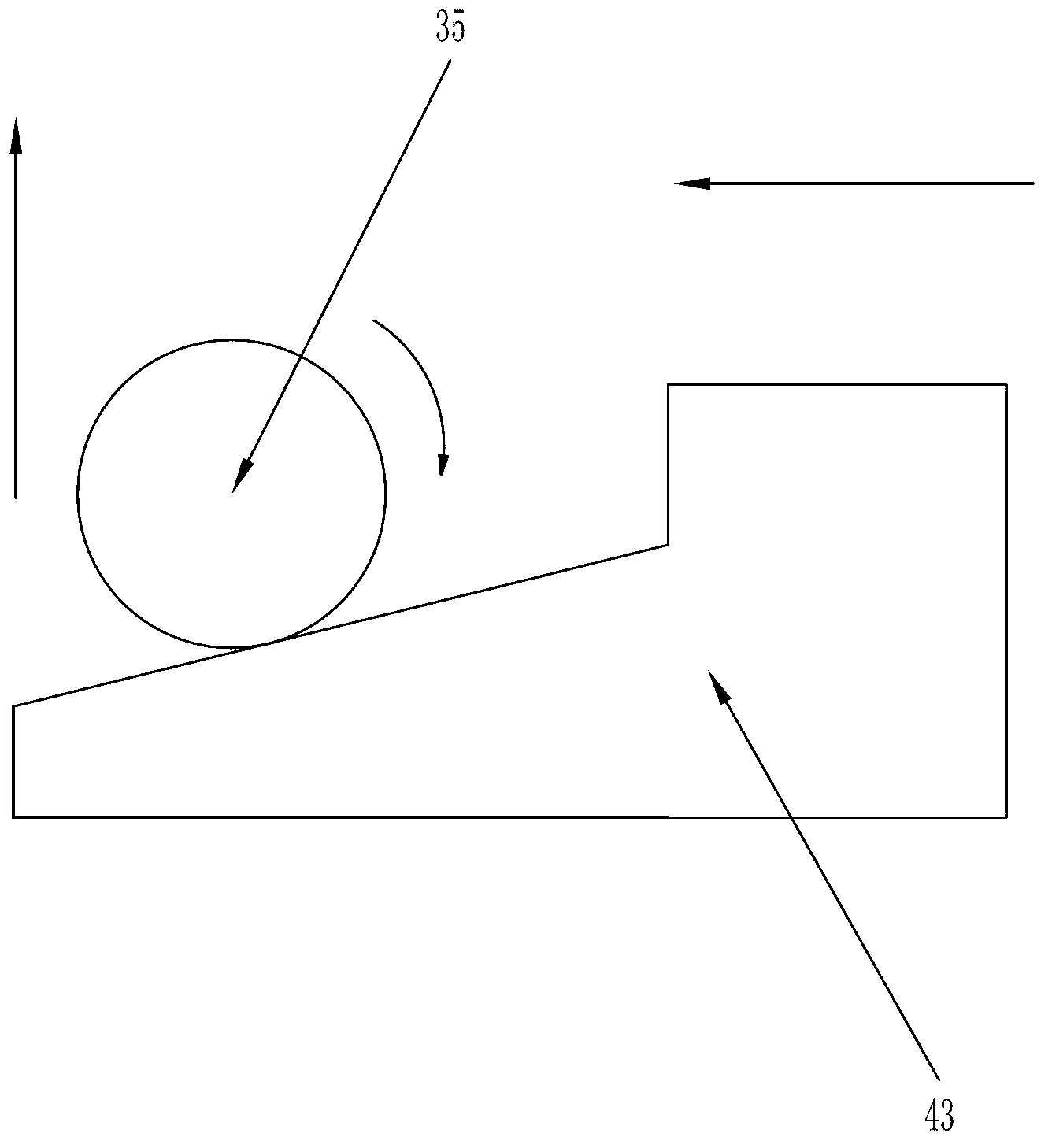

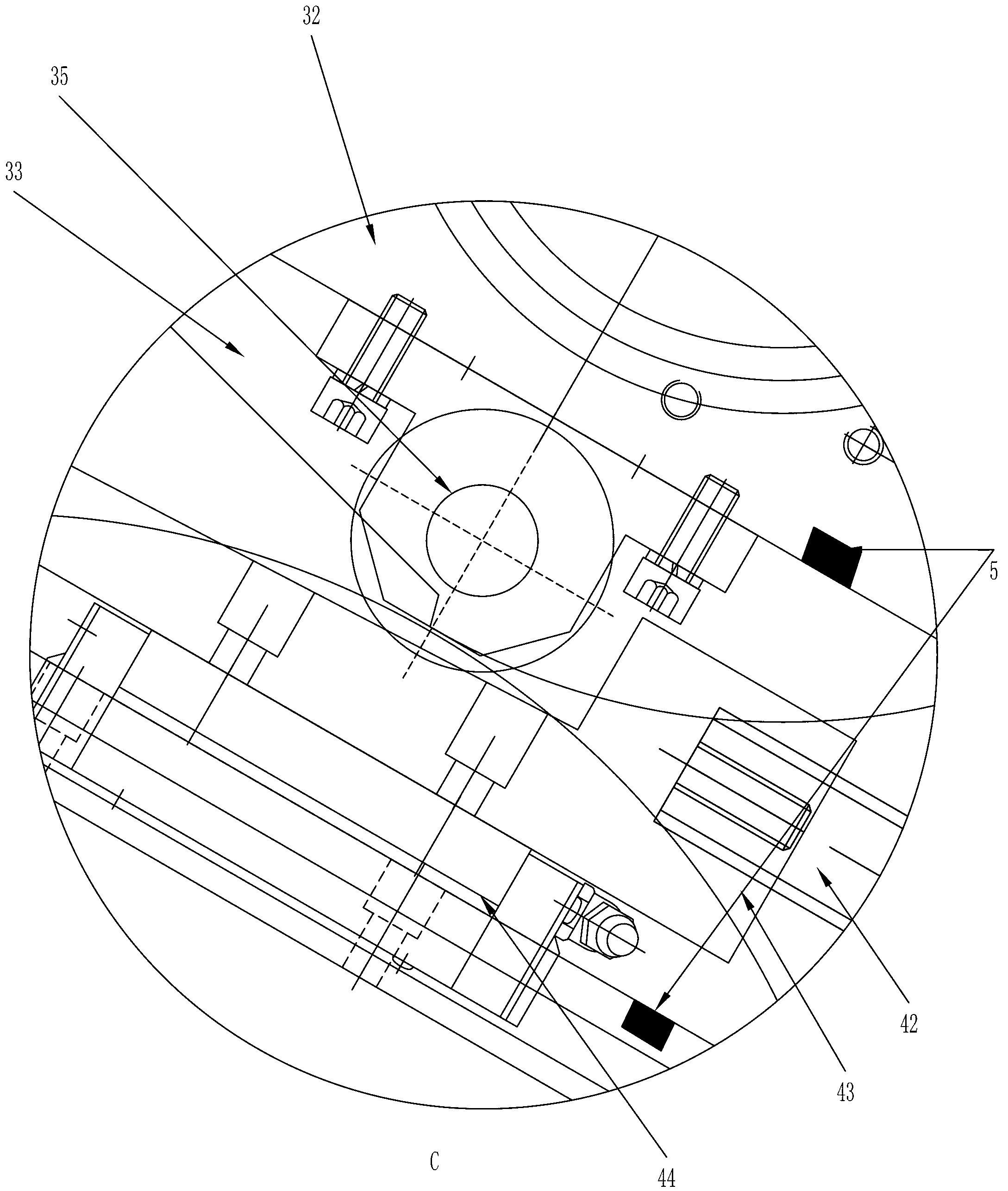

[0021] Such as figure 1 The shown comma blade coating machine includes a frame 1, and the bottom of the frame 1 is provided with a fixed foot 11 fixed on the ground, and a back roller assembly 2 and a comma blade assembly 3 are installed on the frame 1, Between the back roller assembly 2 and the comma scraper assembly 3 , an automatic adjustment device 4 for inclined blocks and an accuracy detection device 5 are provided. The back roller assembly 2 includes a back roller bearing seat 21 fixed on the frame 1, a back roller 22 is installed on the back roller bearing seat 21, and a comma scraper assembly 3 is installed on the side opposite to the back roller 22 , the comma scraper assembly 3 includes a guide rail 31 installed and fixed on the frame 1, a comma scraper bearing seat 32 is provided on the guide rail 31, a comma scraper 33 is installed on the comma scraper bearing seat 32, and a comma scraper 33 is installed on the frame 1 A cylinder 34 is also installed, and the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com