Bearing cleaning machine

A technology for cleaning bearings and bearings, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as harsh working environments and large oil pollution, and achieve good cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

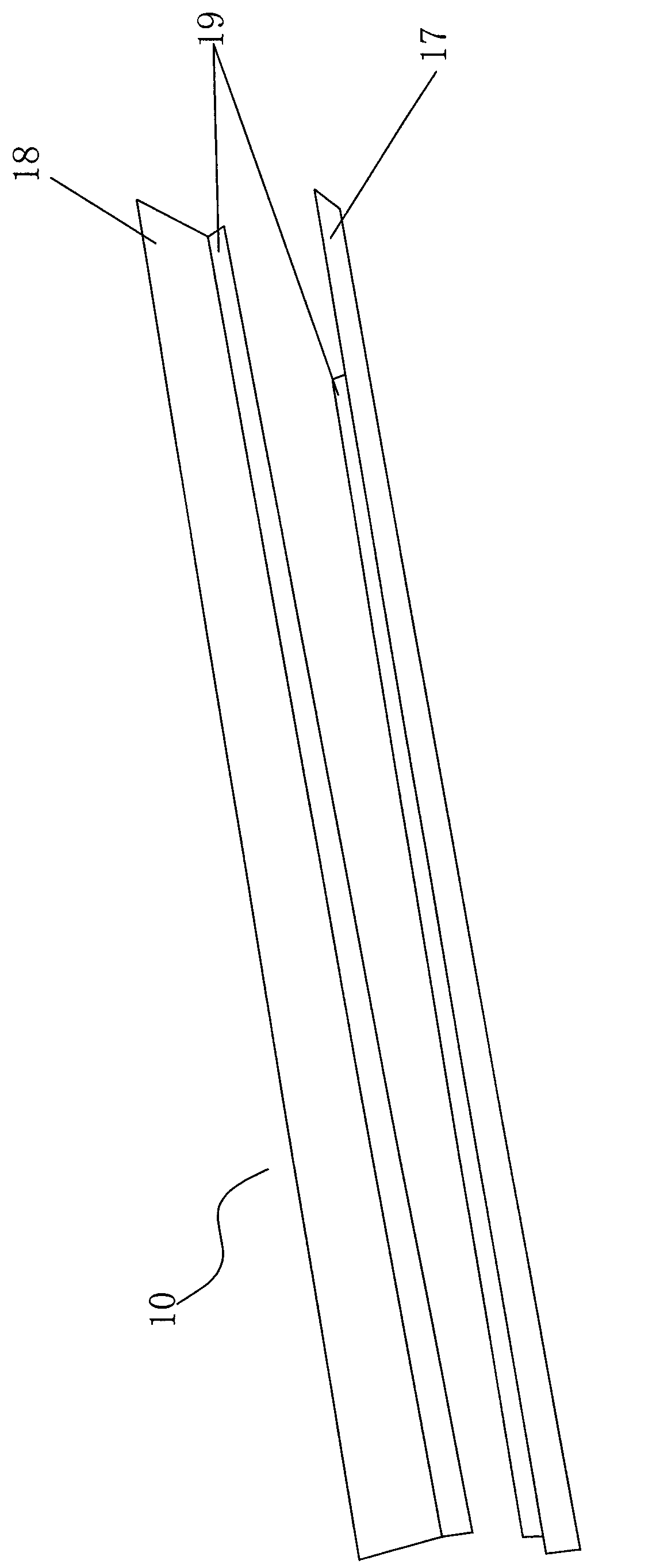

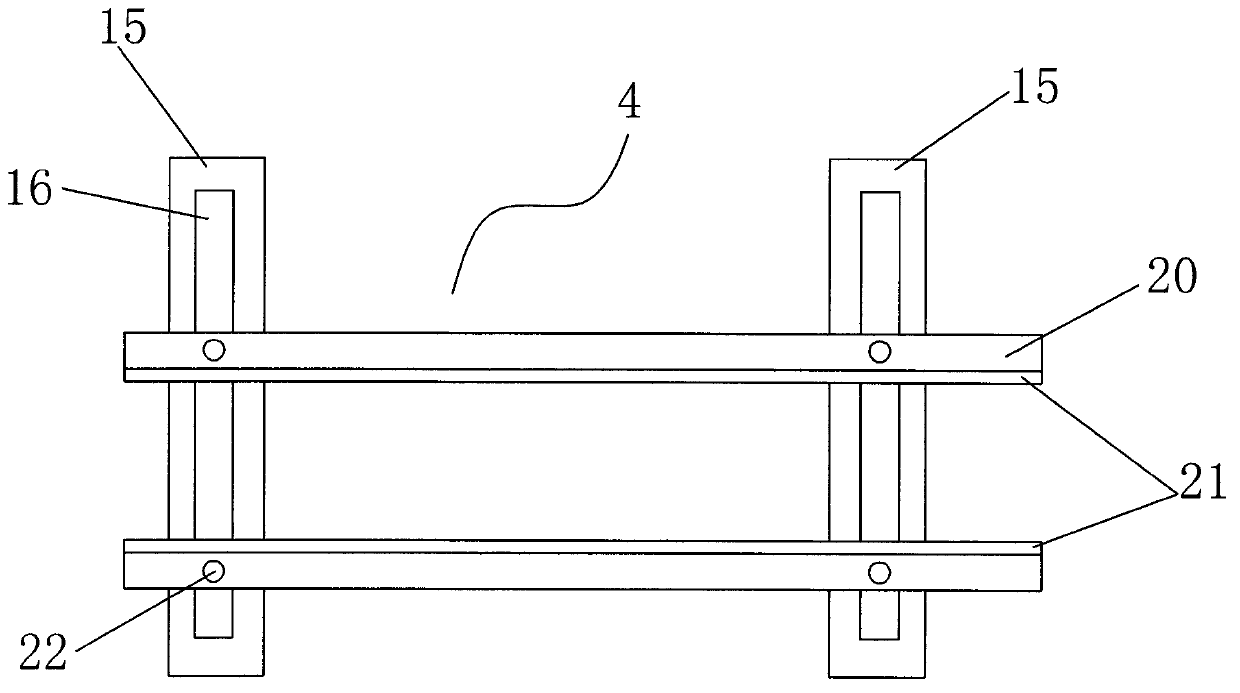

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , a bearing cleaning machine, comprising a frame, the frame has a working platform 1, the front end of the working platform 1 is provided with four feeding vibrating plates 2 for arranging the bearings into a flat queue, and the working platform The front end of 1 is also provided with four horizontal feed rails 3, the input end of the feed rail 3 is connected with the output end of the feeding vibrating plate 2;

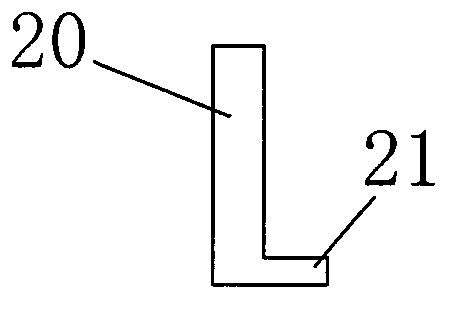

[0031] The working platform 1 is also provided with four front feed rails 4 on which four longitudinal bearings can lie horizontally, the input end of the front feed rail 4 is connected with the output end of the feed rail 3, and the front feed rail 4 is connected with the output end of the feed rail 3. The top of the input end of the feeding track 4 is provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap