Casting machine

A technology of casting machine and reducer, which is applied in casting equipment, control of pouring molten metal from ladle, metal processing equipment, etc., can solve the problems of increased risk, high labor intensity and high price, and improve product quality , the effect of saving labor and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

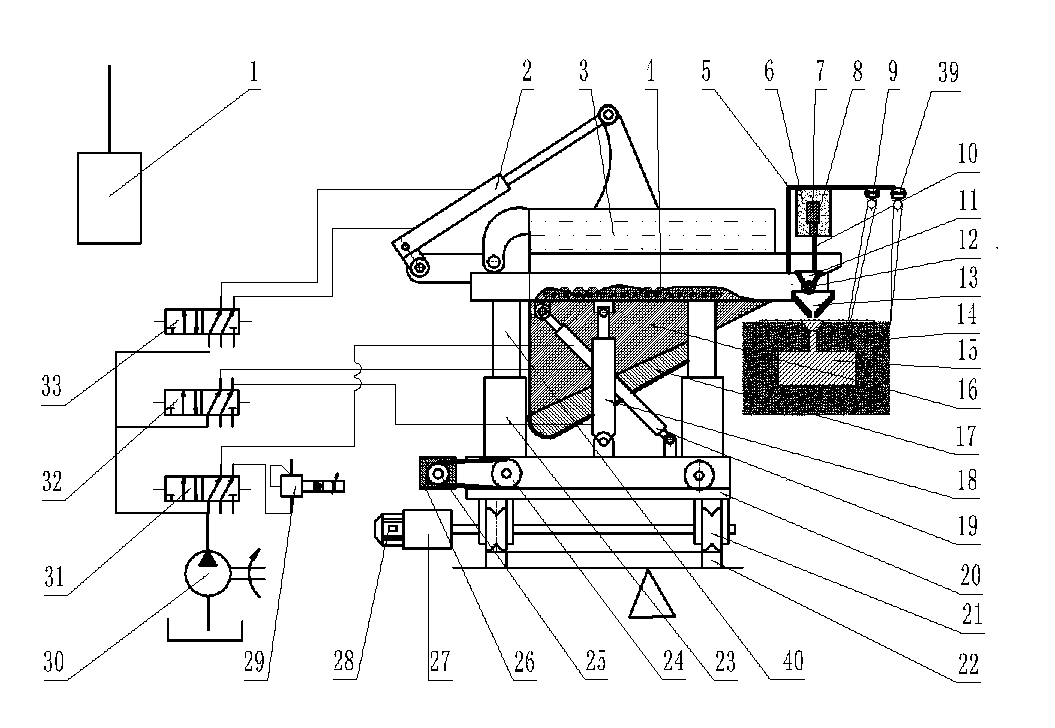

[0019] Example 1: as attached figure 1 , a casting machine, comprising a casting machine frame, a control device, a longitudinal movement mechanism that drives the casting machine frame to move, a lateral movement mechanism that drives the casting machine frame to move, a casting bucket 16 placed on a casting auxiliary bucket 17, and a casting auxiliary bucket that can be adjusted The bucket 17 and the hydraulic cylinder 18 of the casting height of the casting bucket 16 and the guide column 23 installed on the casting machine frame are characterized in that: the guide column 23 is equipped with a guide rod 40 slidingly matched with it, and one end of the guide rod 40 is connected to the The auxiliary casting bucket 17 is connected, and the supporting rod 5 is installed on the auxiliary casting bucket 17. The laser positioner 39 for detecting the position of the sand mold 14 and the laser for detecting the liquid level of the molten iron in the sand mold 14 are installed on th...

Embodiment 2

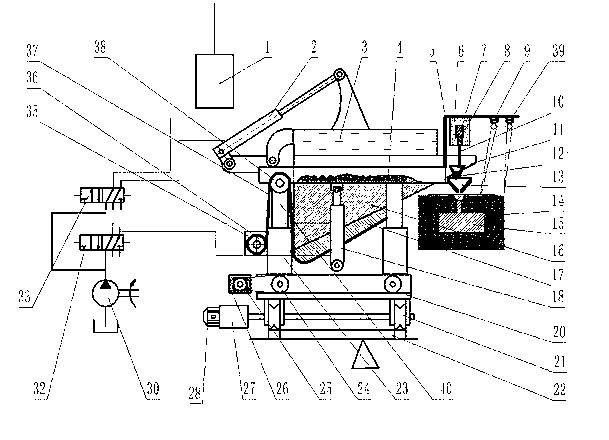

[0029] Example 2: as attached figure 2 , a casting machine, comprising a casting machine frame, a control device, a longitudinal movement mechanism that drives the casting machine frame to move, a lateral movement mechanism that drives the casting machine frame to move, a casting bucket 16 placed on a casting auxiliary bucket 17, and a casting auxiliary bucket that can be adjusted The bucket 17 and the hydraulic cylinder 18 of the casting height of the casting bucket 16 and the guide column 23 installed on the casting machine frame are characterized in that: the guide column 23 is equipped with a guide rod 40 slidingly matched with it, and one end of the guide rod 40 is connected to the The auxiliary casting bucket 17 is connected, and the supporting rod 5 is installed on the auxiliary casting bucket 17. The laser positioner 39 for detecting the position of the sand mold 14 and the laser for detecting the liquid level of the molten iron in the sand mold 14 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com