Multi-temperature mold temperature device for injection molding machine

An injection molding machine, warm-type technology, applied in the field of multi-temperature mold temperature devices, can solve the problems of complex use of injection molding machines, multiple power resources, and increased production costs, so as to reduce the construction area, simplify procedures, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

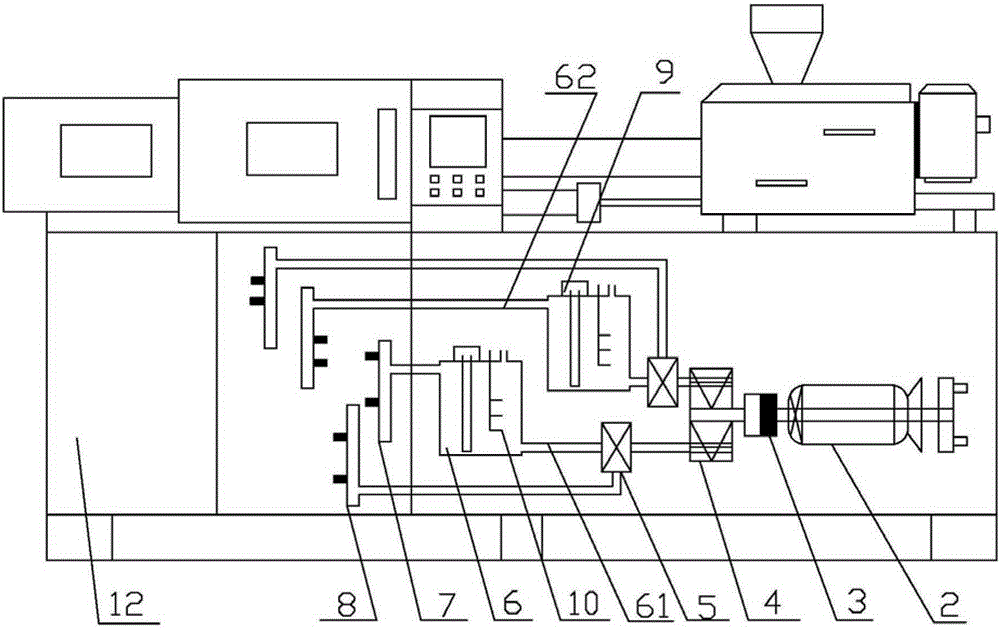

[0020] The present invention will be further described in detail below in conjunction with specific examples, but the present invention is not limited to the following examples. In the following embodiments, the lengthening of the cooling fan end of the rotor shaft of the motor 2 can be obtained by self-processing. The box body 6, the water outlet system 7 and the return water system 8 can all be processed by those skilled in the art, and the rest of the components can be It can be purchased from commercially available products as needed.

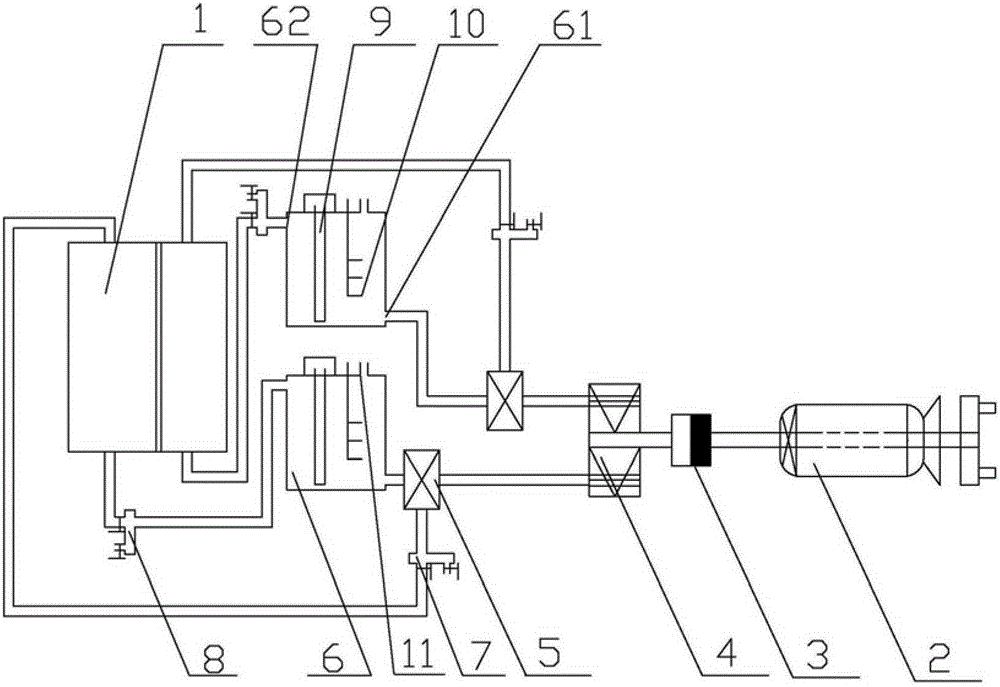

[0021] A multi-temperature mold temperature device for an injection molding machine, including a mold 1 and a motor 2 installed inside the main body 12 of the injection molding machine. Different parts of the mold 1 are provided with media channels that are not connected to each other, and the motor 2 is also included. The clutch 3 connected to the output shaft of the clutch 3 is connected with the output shaft of the clutch 3 with a multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com