Engine suspension

A technology for engine mounts and front mounts, which is applied to power units, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of low vibration isolation rate of engine mounts, achieve novel structure, reduce early damage, and ingenious conception Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

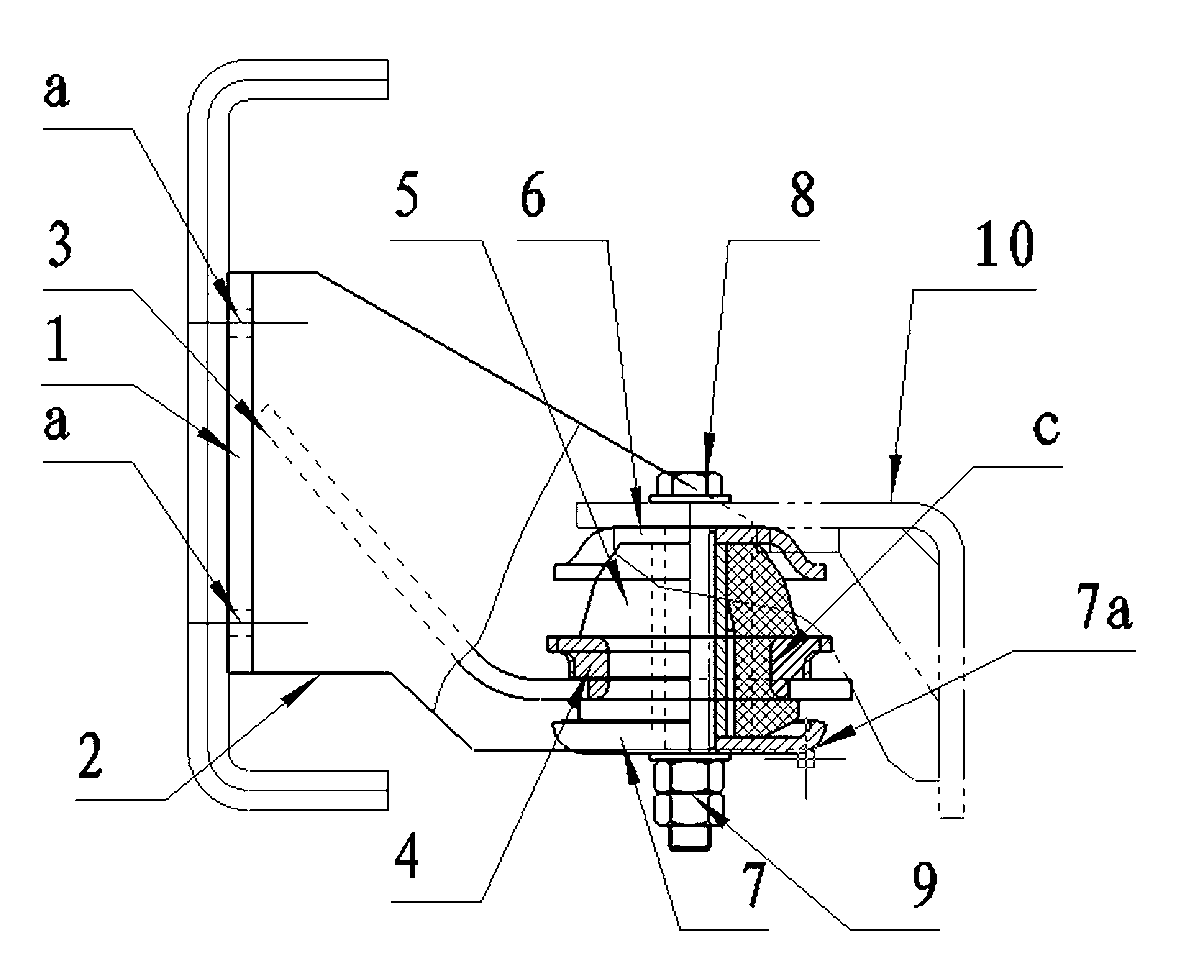

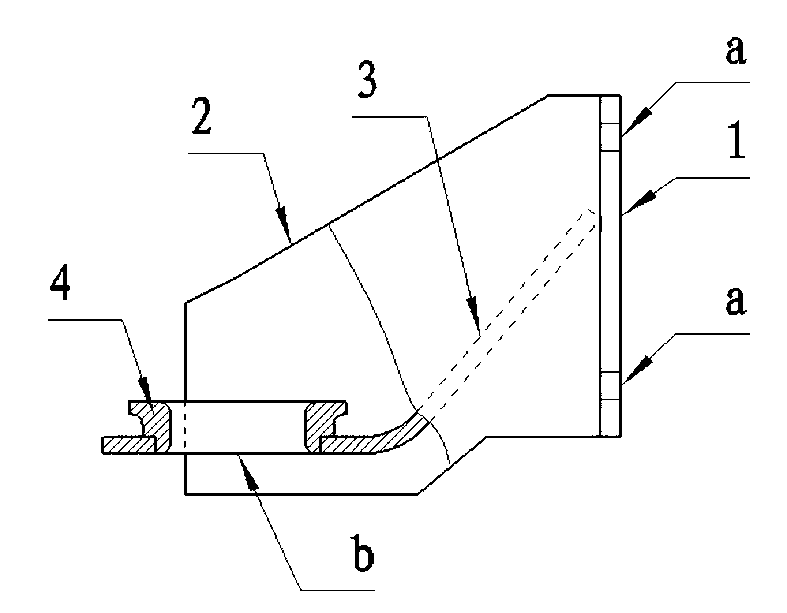

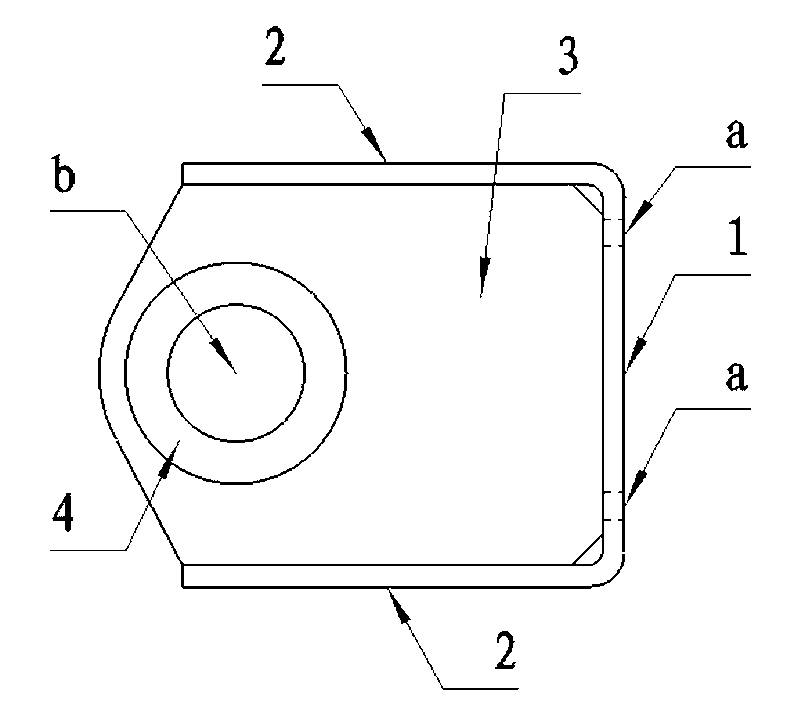

[0031] Engine suspension, including front suspension and rear suspension, the front suspension includes front suspension left bracket assembly, front suspension rubber support assembly and front suspension right bracket assembly, the rear suspension Including rear suspension left bracket assembly, rear suspension rubber support assembly and rear suspension right bracket assembly;

[0032] The front suspension left bracket assembly includes a main board 1 with a mounting hole a, two side boards 2 fixedly connected to both sides of the main board 1 and perpendicular to the main board 1, and a connecting board 3, and the two side boards 2 pass through The connecting plate 3 is fixed together, and the connecting plate 3 is provided with an assembly hole b, and an annular front support seat 4 is fixedly sleeved in the assembly hole b;

[0033] The front suspension rubber support assembly includes a front shock-absorbing rubber block 5 with a through hole longitudinally, a front upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com