A kind of vibration absorber for main reducer of automobile

A main reducer and vibration absorber technology is applied in the field of automobile shock absorption and noise reduction, which can solve the problems of poor mitigation effect of pure rubber mounts, reduced vibration reduction effect, and easy aging of rubber, so as to achieve overall simplicity and practicality, and reduce pitching vibration. , The effect of the best vibration absorption and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

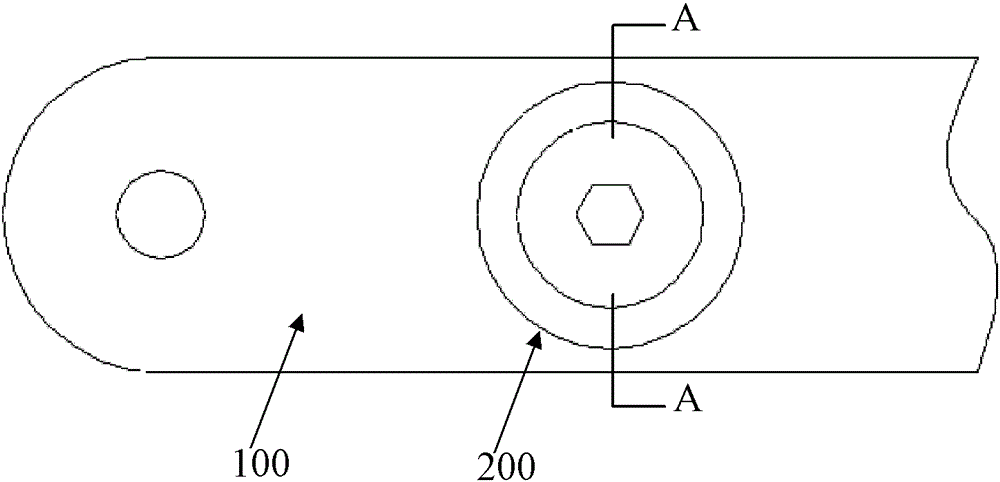

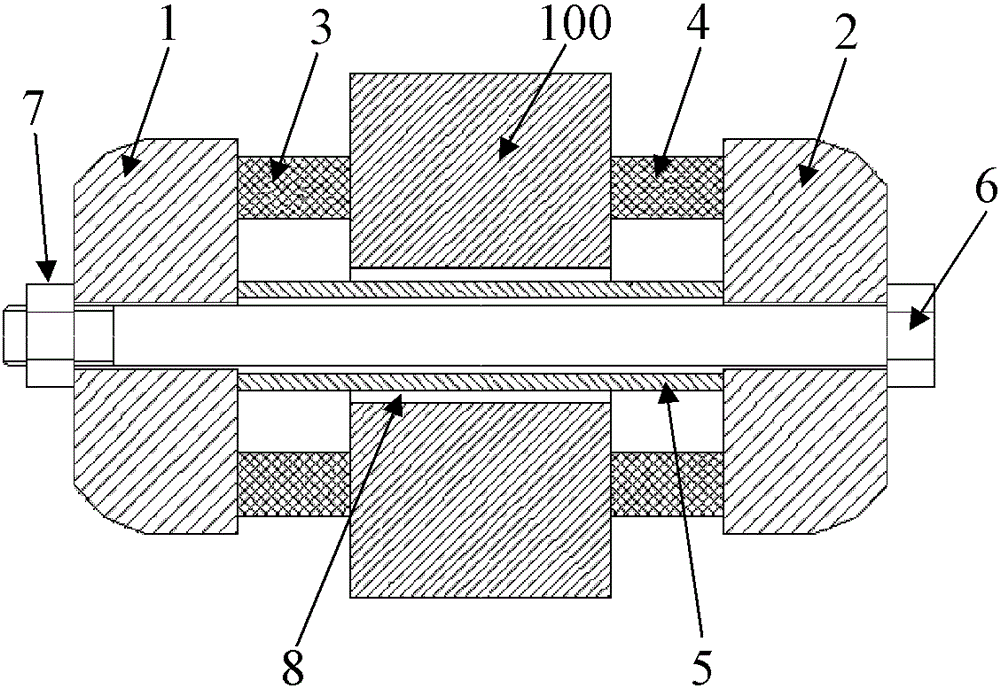

[0026] figure 1 It shows a structural schematic view of the vibration absorber installed on the main reducer of the automobile in this embodiment, figure 2 yes figure 1 A-A view in . In this embodiment, the shock absorber 200 is installed on the front trailing arm 100 of the final drive. The shock absorber 200 includes a mass block and an elastic block. The trailing arm 100 is in direct contact, and the mass blocks are arranged outside the elastic blocks on both sides, so that the elastic blocks are located between the mass block and the front trailing arm 100 of the final drive.

[0027] refer to figure 2 , the shock absorber 200 specifically includes a first elastic block 3 and a second elastic block 4 located on both sides of the front trailing arm 100 of the final drive. The two elastic blocks are directly in contact with the front trailing arm 100 of the final drive. The first mass block 1 and the second mass block 2 are respectively provided, that is, the first ela...

Embodiment 2

[0033] The structure of the vibration absorber for the main reducer of the automobile in this embodiment is similar to the structure of the vibration absorber in Embodiment 1, and the only difference lies in the composition of the mass block. In Embodiment 1, both the first mass block 1 and the second mass block 2 are made of an integral metal material such as steel or iron, and in this embodiment, in order to make the vibration absorber suitable for different vibration frequencies of the main reducer, the The first mass block 1 and the second mass block 2 are respectively arranged as structures with adjustable weights.

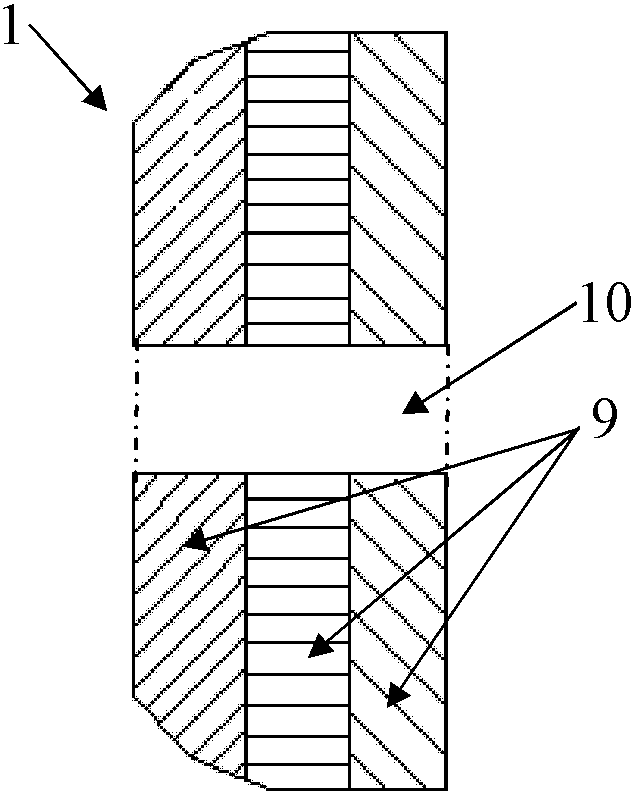

[0034] image 3 A schematic stacking diagram of the first mass 1 in this embodiment is shown, and the structure of the second mass 2 is the same as that of the first mass 1 . Specifically, the first mass 1 includes several unit blocks 9 stacked along its axial direction. The several unit blocks 9 are hollow cylinders with the same inner diameter and coaxial ...

Embodiment 3

[0037] The structure of the vibration absorber for the main reducer of the automobile in this embodiment is similar to the structure of the vibration absorber in Embodiment 2, the difference lies in the stacking manner of the unit blocks of the mass blocks.

[0038] Figure 4 A schematic stacking diagram of the first mass 1 in this embodiment is shown, and the structure of the second mass 2 is the same as that of the first mass 1 . Specifically, the first quality block 1 includes several unit blocks 9 stacked along its radial direction, and the several unit blocks 9 are hollow cylinders arranged coaxially, and the outer diameter of the innermost unit block is equal to the outer diameter of the unit nested outside it. block inner diameter, and so on, several unit blocks are set together in 9 sets. If the inner diameter of the unit block 9 of the outer layer is greater than the outer diameter of the nut 7, the outer unit block 9 will fall off. In order to avoid the above situa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com