Modular built-in PTRMD precast concrete block and fan vibration control method

A prefabricated concrete and concrete block technology, applied in non-rotational vibration suppression, wind power generation, installation/support of wind turbine configuration, etc., can solve the problems of low vibration frequency, negative damping, difficulty in controlling frequency, etc. , Improve the service life and reduce the effect of pitching vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0044] see Figure 5 , the following Spar-type fan is described by taking the OC3-hywind floating fan platform proposed by the National Renewable Energy Laboratory NREL as an example.

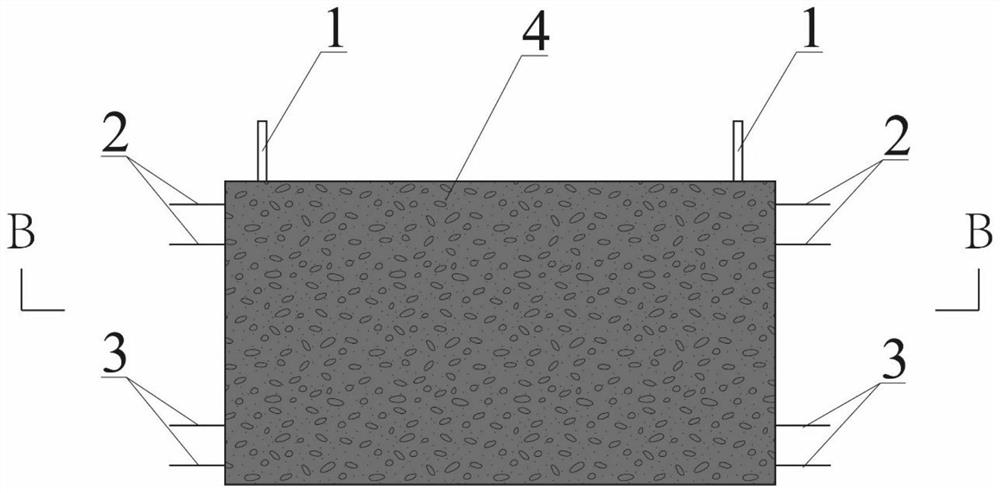

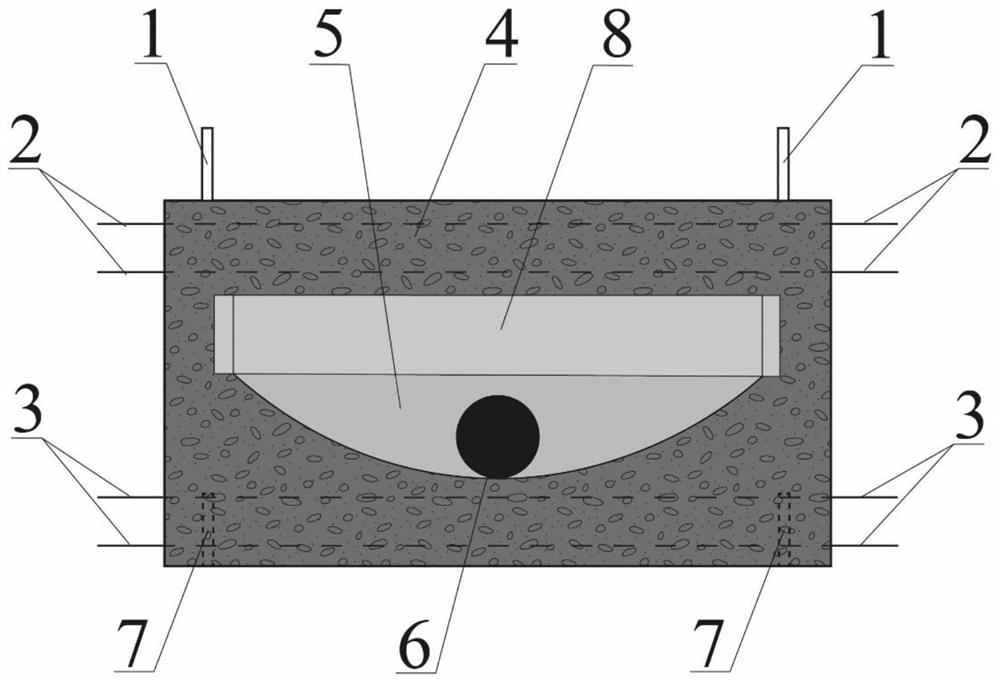

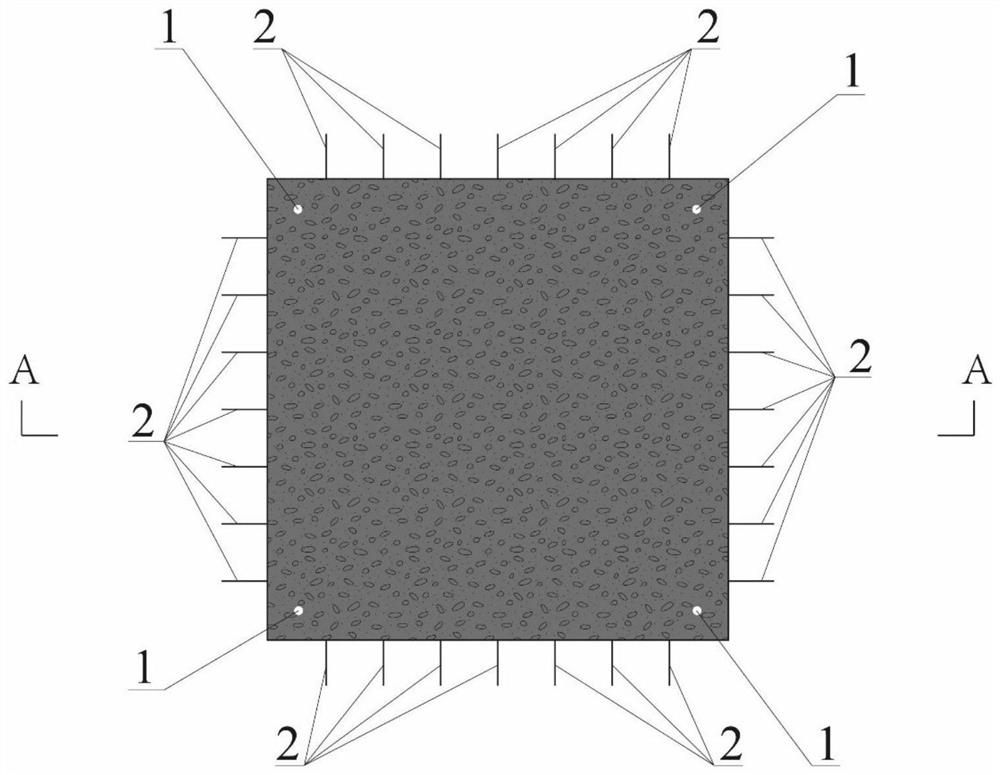

[0045] like figure 1 , 2 As shown in 3 and 4, the modular built-in PTRMD prefabricated concrete block 19 of the embodiment of the present invention includes a pre-embedded positioning steel pipe 1, a reserved connection steel bar 2 for the top plate, a reserved connection steel bar for the bottom plate 3, and a prefabricated cavity concrete block 4. , Cavity bottom surface anti-wear coating 5, steel ball 6, reserved positioning hole 7 and viscoelastic material 8.

[0046] The prefabricated concrete block 19 with built-in PTRMD is modular prefabricated, and multiple modules are processed in the factory and transported to the location where the fan is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com