Operation structure and operation method thereof

A control structure and joystick technology, which is applied in the direction of rudder steering, etc., can solve the problems of occupying a large position on the console, bulky and bloated mechanism, and unsightly straight slots, so as to achieve simple structure, prevent failures and operation errors , Improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

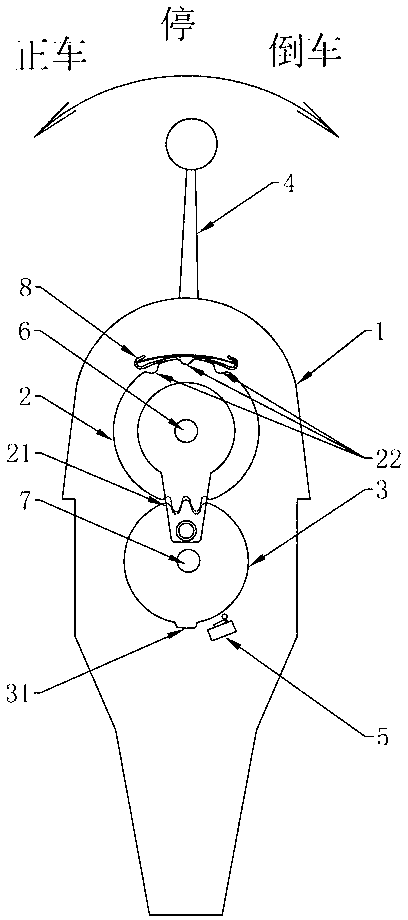

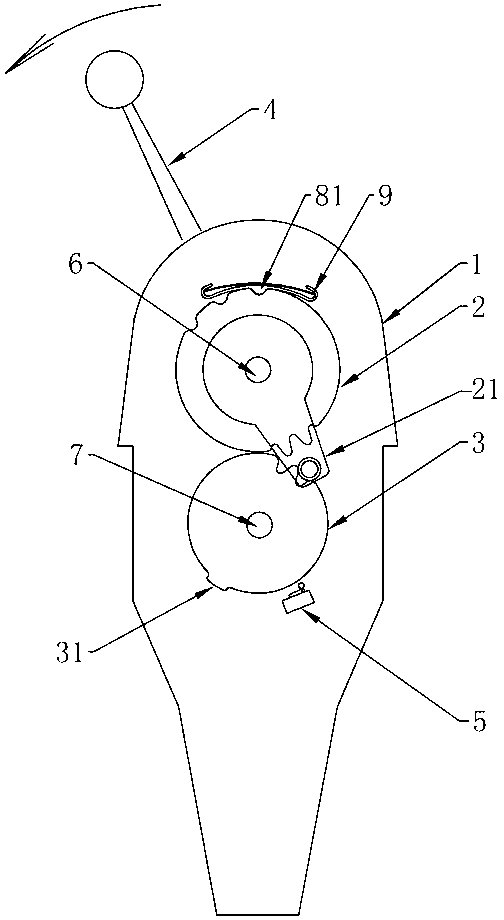

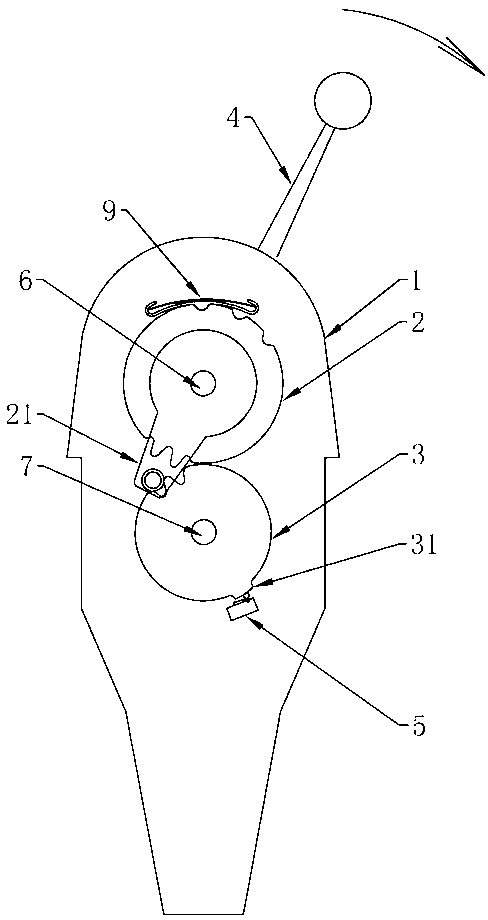

[0021] Such as Figure 1 to Figure 3 As shown, the control structure includes a housing 1, a flywheel 2, a steering wheel 3, a joystick 4 and a micro switch 5 fixedly arranged on the housing 1, and the housing 1 is provided with There is a rotating shaft connected in rotation with the housing 1 6 and the axis of rotation 7. The flywheel 2 and the rotating shaft 6 fixedly connected, the steering wheel 3 and the rotating shaft 7 is fixedly connected, the flywheel 2 is in transmission connection with the steering wheel 3, and the joystick 4 is fixedly arranged on the flywheel 2 or the rotating shaft 6, a flexible shaft fixing rod 21 is fixedly arranged on the flywheel 2, the free end of the flexible shaft fixing rod 21 is downwards, and the steering wheel 3 is provided with a The matching protrusion 31, the micro switch 5 can be turned on or off by turning the steering wheel 3.

[0022] In this example, if figure 1 As shown, the joystick 4 is in the middle position, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com