Volumetric quantitive mushroom filling machine

A volumetric filling machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of large quantitative error, high labor intensity, low efficiency, etc., and achieve the effect of realizing controllability and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

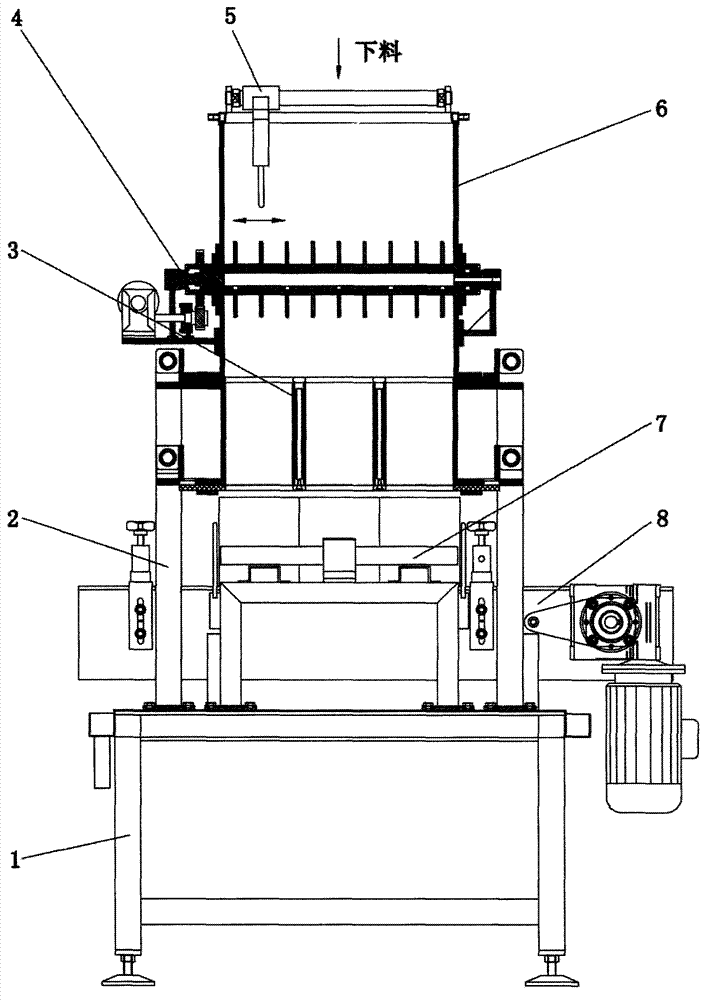

[0022] like figure 1 As shown, the mushroom volumetric quantitative filling machine consists of a chassis 1, a filling support 2, a material box 6, a quantitative filling device 3, a raking mechanism 4, a raking mechanism 5, a conveying channel 8, and a can pushing mechanism 7. The base frame 1 is equipped with a filling support 2 . The upper part of the filling support 2 is provided with a quantitative filling device 3 , and the lower part of the filling support 2 is provided with a conveying channel 8 and a can pushing mechanism 7 . A feed box 6 is arranged above the quantitative filling device 3 , a raking mechanism 4 is set up on the bottom of the feed box 6 , and a raking mechanism 5 is set on the top of the feed box 6 .

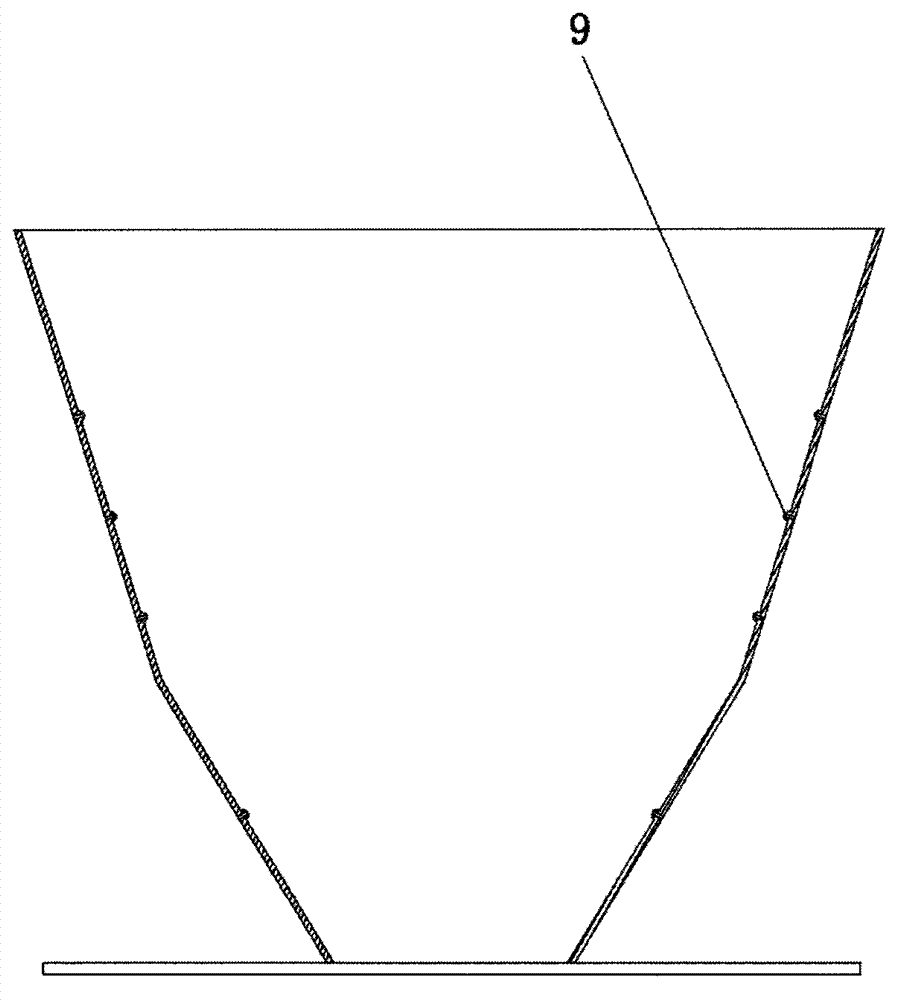

[0023] like figure 2 As shown, the wall body of the material box 6 is provided with several concave-convex points 9, and offers air holes on the concave-convex points.

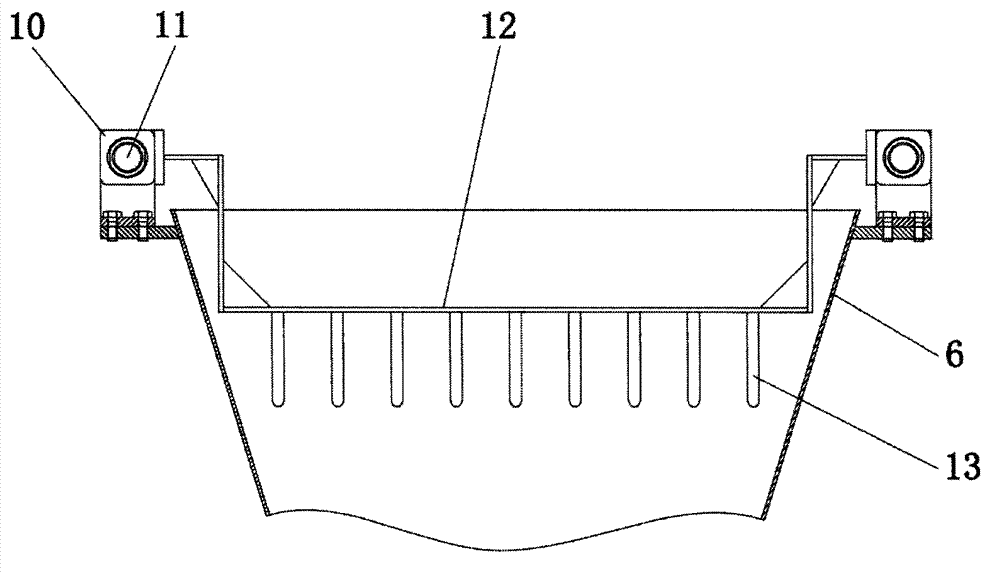

[0024] like image 3 The shown raking mechanism 5 is made up of rodless cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com