Low-viscosity low-contact angle cold tolerance ultraviolet light polymerization adhesive for bonding glass and preparation method thereof

An ultraviolet light, low viscosity technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1

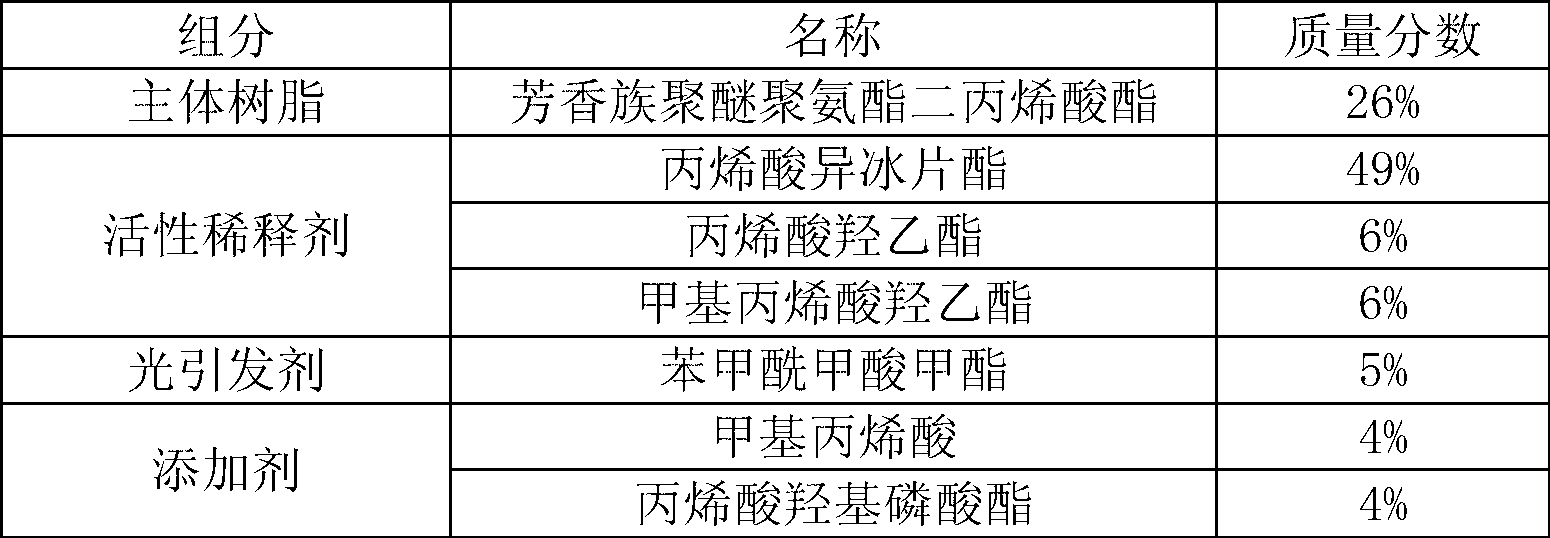

[0035] Table 1 selects the following components by mass percent fraction:

[0036]

[0037] The method for preparing Example 1 is: first weigh each material according to the components given in Table 1; then put the aromatic polyether urethane diacrylate into a light-tight brown glass container (select the light-proof brown glass container In order to achieve shading and prevent monomers from reacting), then sequentially pour isobornyl acrylate, hydroxyethyl acrylate, hydroxyethyl methacrylate, methyl benzoylformate, methacrylic acid and hydroxyphosphate acrylate; After a stirring speed of 60 rpm and a stirring time of 5 minutes, a uniformly stirred and mixed UV-curable adhesive was prepared.

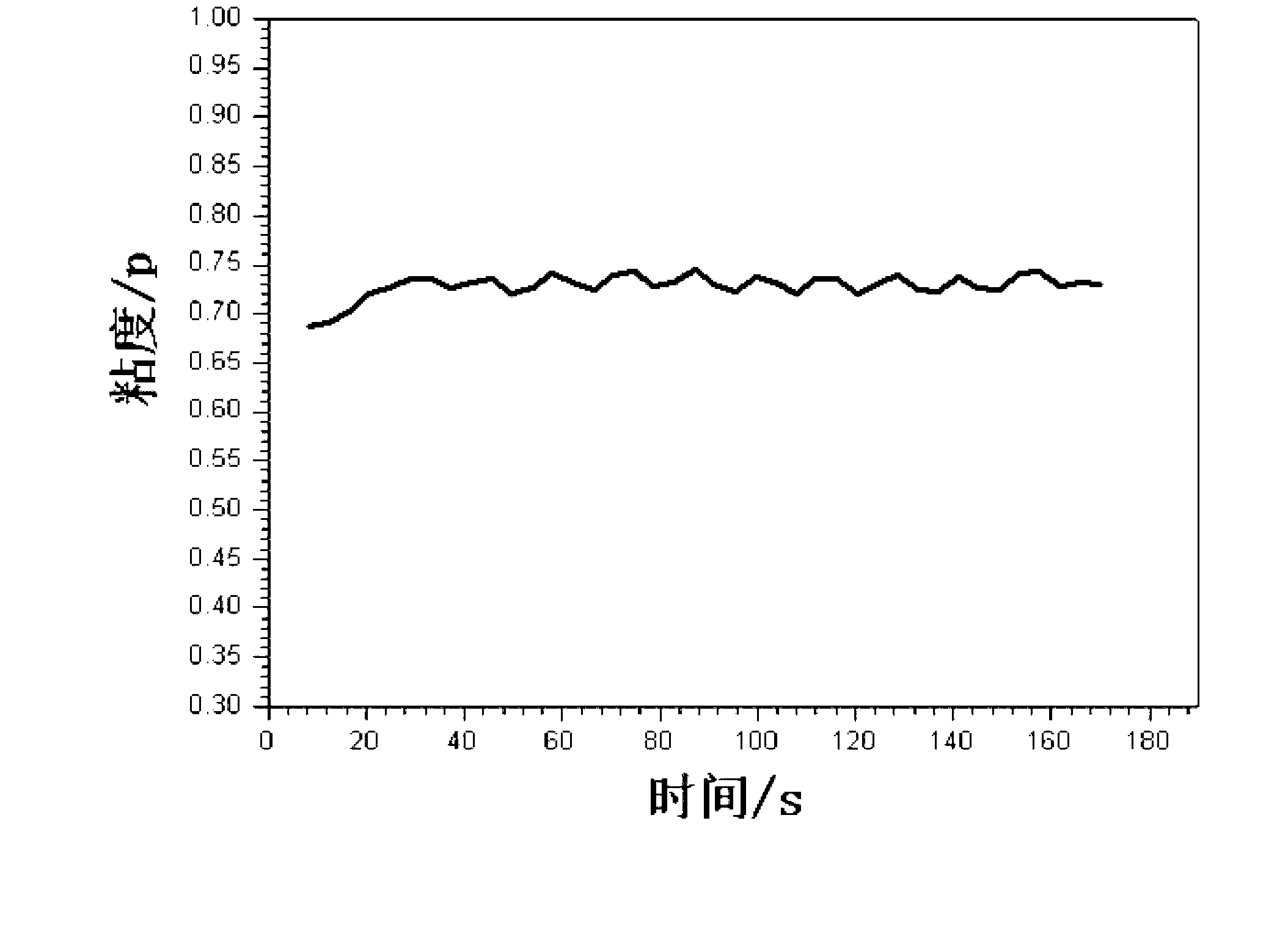

[0038] The UV-curable adhesive prepared in Example 1 was subjected to a viscosity test. The test equipment was a British BohlinrhRH 2000 rotational rheometer, and the viscosity test method was the plate method. figure 2 It is the viscosity test result of the U...

Example Embodiment

[0042] Example 2

[0043] Table 2 selects the following components by weight percent fraction:

[0044]

[0045]

[0046] The method for preparing Example 2 is as follows: first weigh each material according to the components given in Table 2; then put aromatic polyurethane diacrylate and aromatic epoxy diacrylate into a light-tight metal container, and then sequentially Pour isobornyl acrylate, hydroxyethyl acrylate, polyethylene glycol diacrylate, methyl benzoylformate, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, acrylic acid, N- Methylol acrylamide and acrylic acid hydroxyphosphate; after a stirring speed of 40 rpm and a stirring time of 10 minutes, a uniformly stirred and mixed UV-curable adhesive is obtained.

[0047] The UV-curable adhesive prepared in Example 2 was subjected to a viscosity test. The test equipment was a British BohlinrhRH 2000 rotational rheometer, and the viscosity test method was the plate method. The test results show that the average v...

Example Embodiment

[0051] Example 3

[0052] Table 3 selects the following components by weight percent fraction:

[0053]

[0054]

[0055] The method for preparing Example 3 is: first weigh each material according to the components given in Table 3; then aromatic polyether urethane diacrylate and aliphatic polyether urethane diacrylate are put into an opaque brown glass container , and then sequentially poured into isobornyl acrylate, hydroxyethyl acrylate, trimethylolpropane triacrylate, glycidyl methacrylate, 1-hydroxycyclohexyl phenyl ketone, benzophenone, methacrylic acid , acrylic acid hydroxyphosphate and N-methylol acrylamide; at a stirring speed of 150 rpm and a stirring time of 5 minutes, a uniformly stirred and mixed UV-curable adhesive is prepared.

[0056] The UV-curable adhesive prepared in Example 3 was subjected to a viscosity test. The test equipment was a British BohlinrhRH 2000 rotational rheometer, and the viscosity test method was the plate method. The test result...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap