Top distribution device and distribution method for blast furnace

A distributing device and distributing technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of insufficient opening degree, time-consuming oil cleaning, complicated structure, etc., and achieve simple structure, continuous and stable operation, active and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

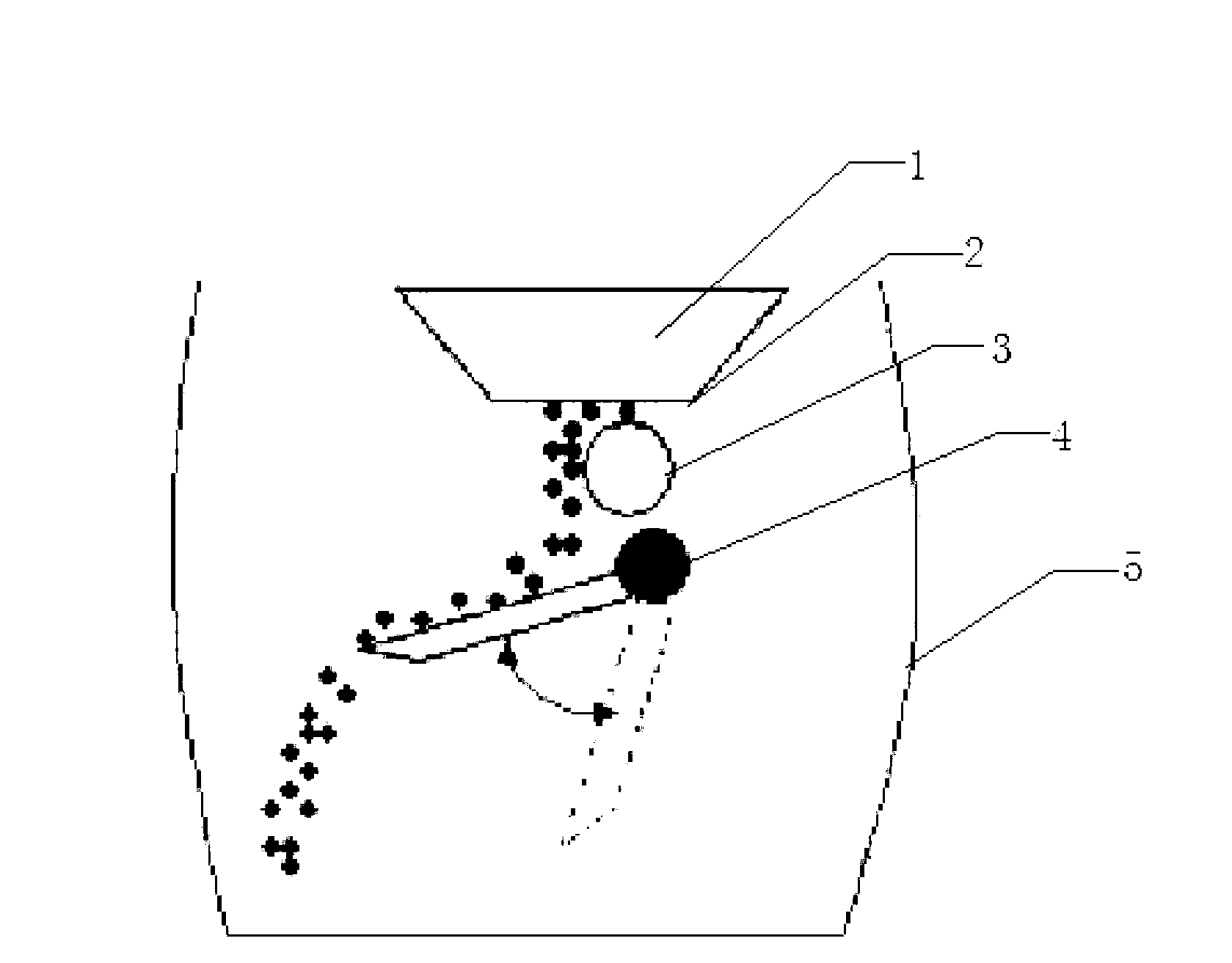

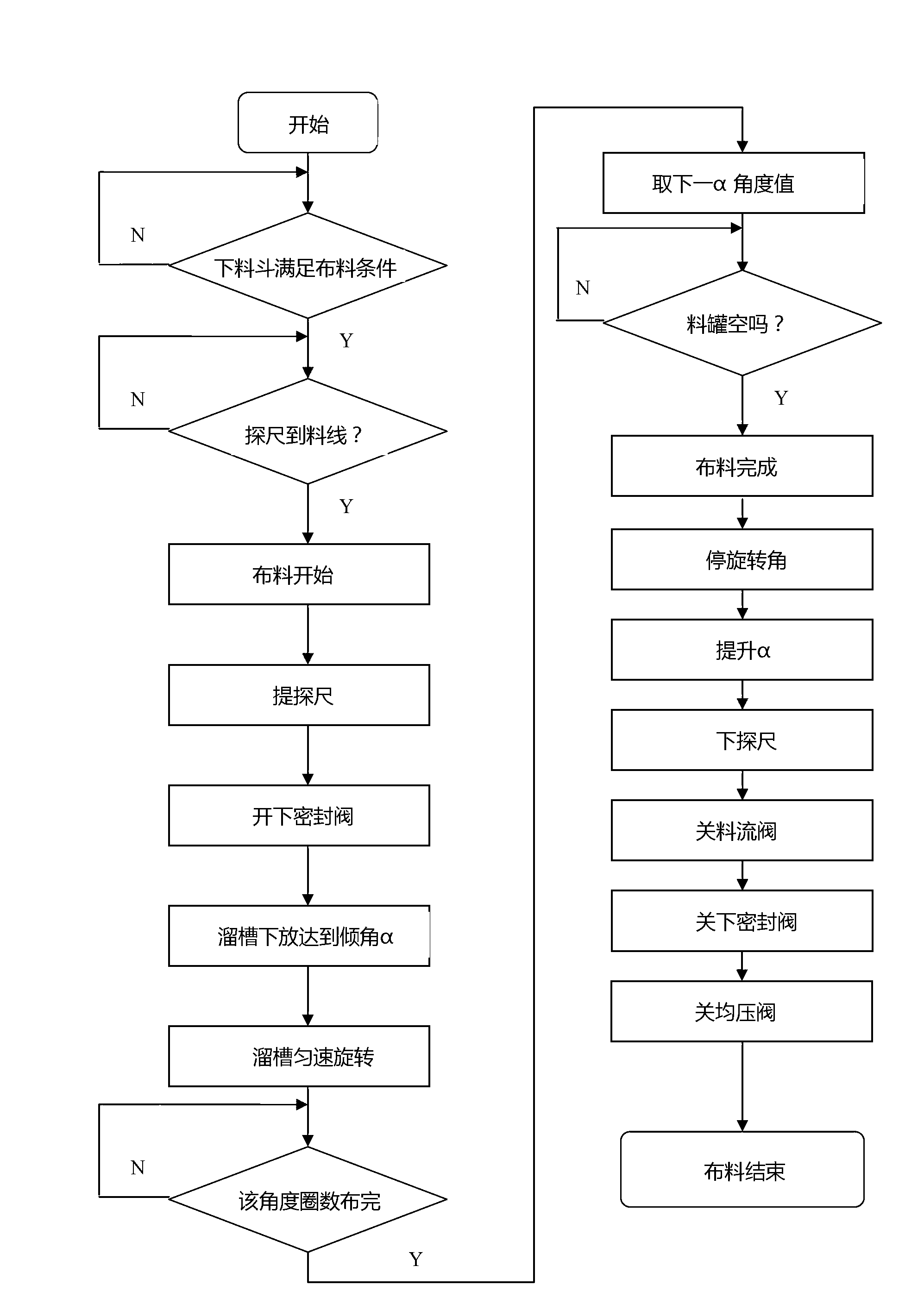

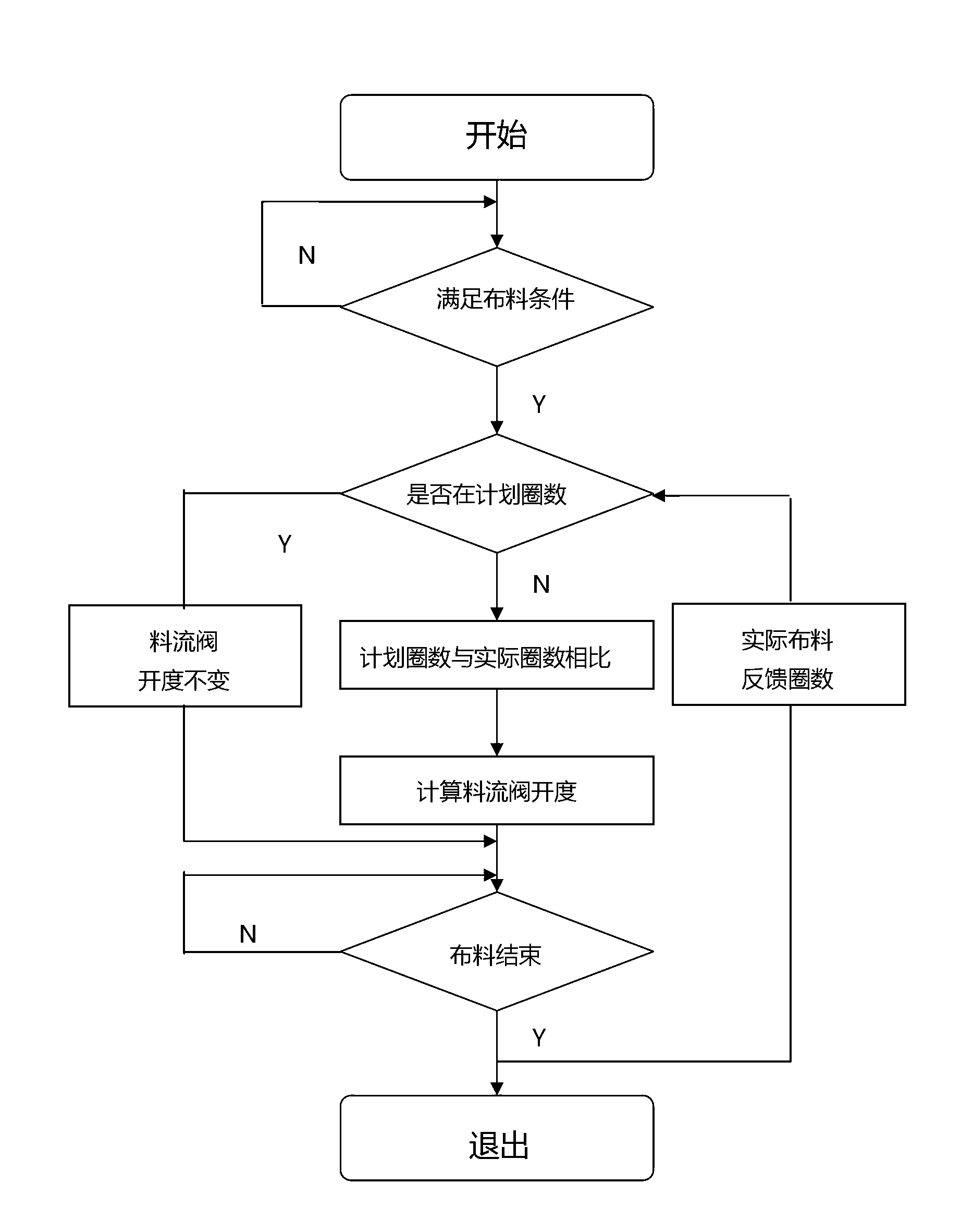

[0023] A blast furnace top distribution device provided in this embodiment, its structural schematic diagram is as follows figure 1 As shown, it includes a material flow regulating valve 2, a drum 3, a chute 4, a probe and a PLC control device. The material flow regulating valve 2 is arranged at the bottom of the lower hopper 1; the drum 3 is arranged at the lower part of the material flow regulating valve 2, and the chute 4 is arranged below the roller 3 through a roller device. There are two probes, which are located below the chute 4, close to the furnace wall 5, and arranged opposite to each other at 180 degrees; the PLC control device is connected with the material flow regulating valve (2) and the chute (4) to control The opening angle γ of the material flow regulating valve (2), the inclination angle α of the chute (4), and the angle β at which the chute (4) rotates at a constant speed.

[0024] This method realizes the precise angle control of the opening degree by re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com