Sewing machine cloth collecting device

A material collecting device and sewing machine technology, which is applied to sewing machine components, garment piece collecting devices, sewing equipment and other directions, can solve the problems of reducing labor efficiency and reducing sewing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

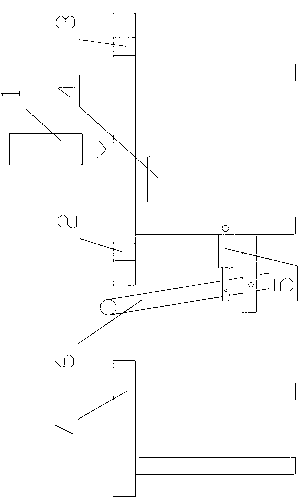

[0011] The accompanying drawing is an embodiment of the present invention, which is specifically described in conjunction with the accompanying drawings, including the sewing machine body 1, light intensity sensor I2, light intensity sensor II3, controller 4, telescopic cylinder 5, lever 6 and placement The stool 7 is provided with a light intensity sensor I2 and a light intensity sensor II3 respectively at the front and rear ends of the sewing thread of the sewing machine body 1, and the light intensity sensor I2 and the light intensity sensor II3 are arranged on the workbench of the sewing machine body 1 and It is set to be connected with the fabric in a contact manner, the output ports of the light intensity sensor I2 and the light intensity sensor II3 are set to be connected to the input port of the controller 4, the placing stool 7 is arranged at the discharge end of the sewing machine body 1, and the placing stool 7 and the A driving lever 6 is arranged between the sewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com