Centrifugal fan impeller, centrifugal fan and snow blowing vehicle

A centrifugal fan and impeller technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of difficulty in adapting to the gas flow characteristics inside the fan, increase the friction between the air flow and the blades, and the low aerodynamic efficiency of the fan, and achieve the overall goal of the fan. Improve efficiency, reduce drag coefficient, and prevent eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

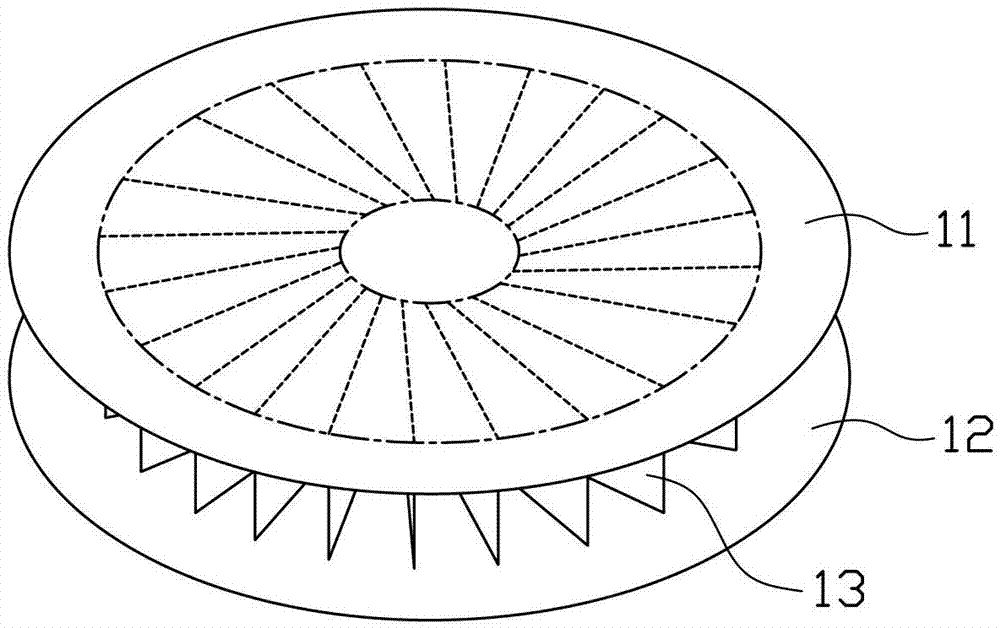

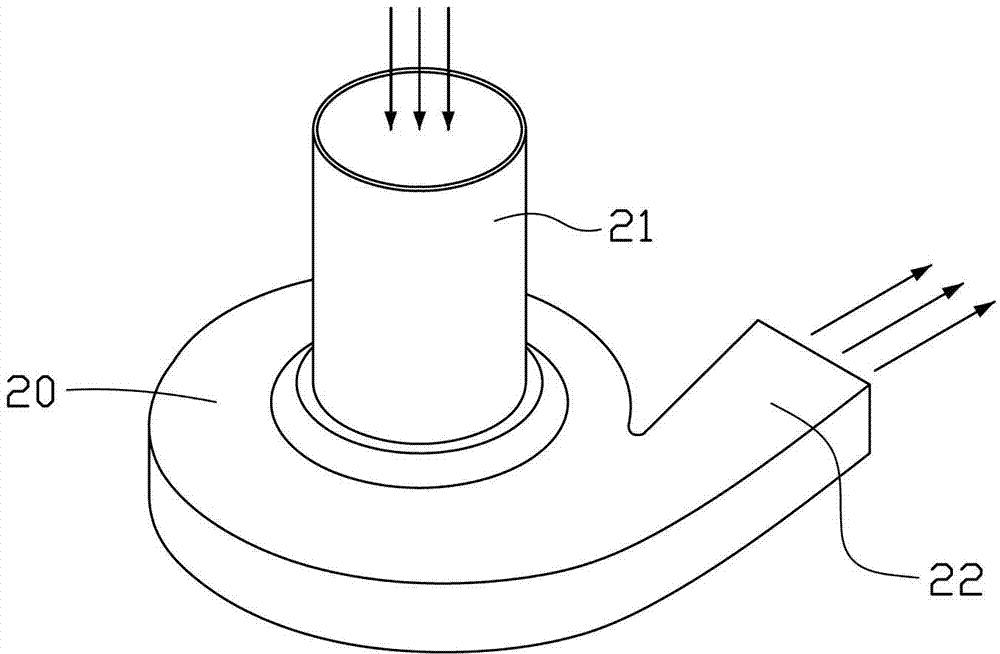

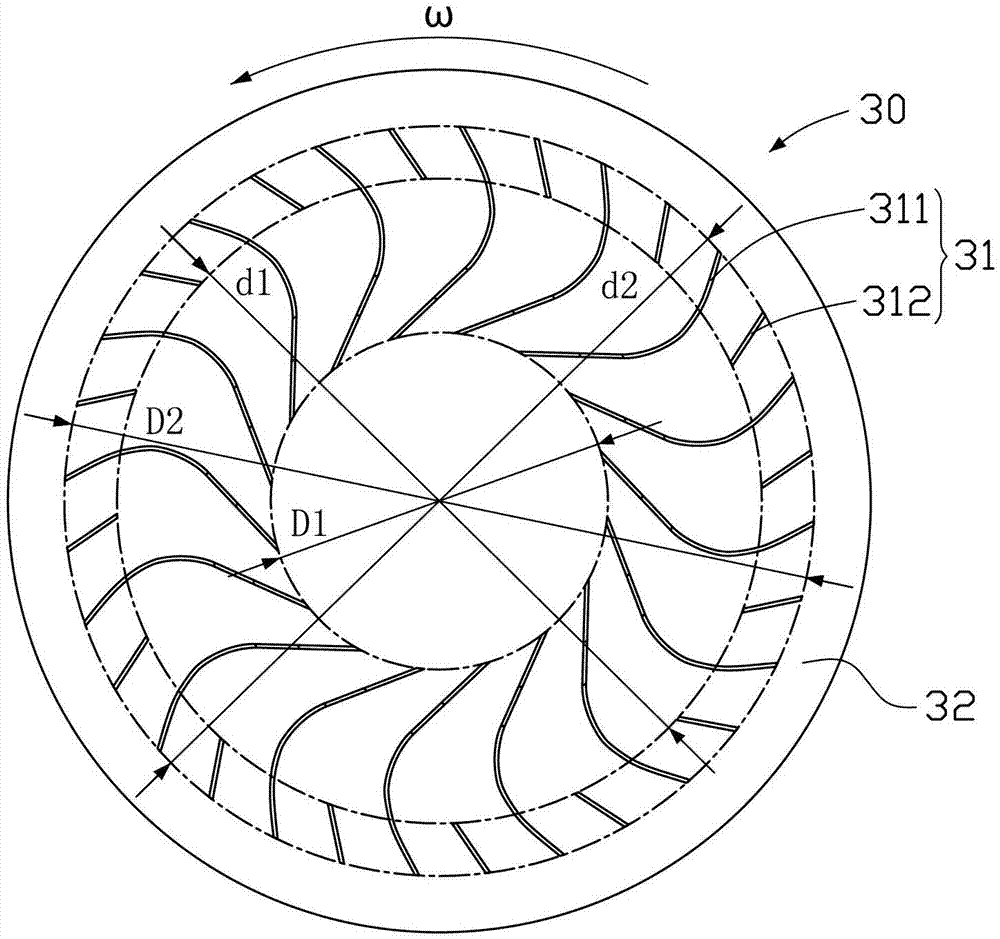

[0031] figure 2 is a schematic structural view of the centrifugal fan provided by the first embodiment of the present invention, image 3 It is a structural schematic diagram of the centrifugal fan impeller provided by the first embodiment of the present invention, please refer to figure 2 and image 3 The centrifugal fan includes a casing 20 and an impeller 30 arranged in the casing 20. The casing 20 is provided with an air inlet 21 and an air outlet 22. The air inlet 21 is set corresponding to the axial center of the centrifugal fan, and the air outlet 22 corresponds to the centrifugal fan. The circumferential tangential position is set, and the air inlet 21 is perpendicular to the air outlet 22.

[0032] The impeller 30 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com