Membrane positioning structure, backlight module and display device

A technology for positioning structures and membranes, applied in lighting and heating equipment, optics, electric light sources, etc., can solve the problem of taking up a lot of space, and achieve the effect of small space occupation, simplified design, and promotion of narrow edge development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

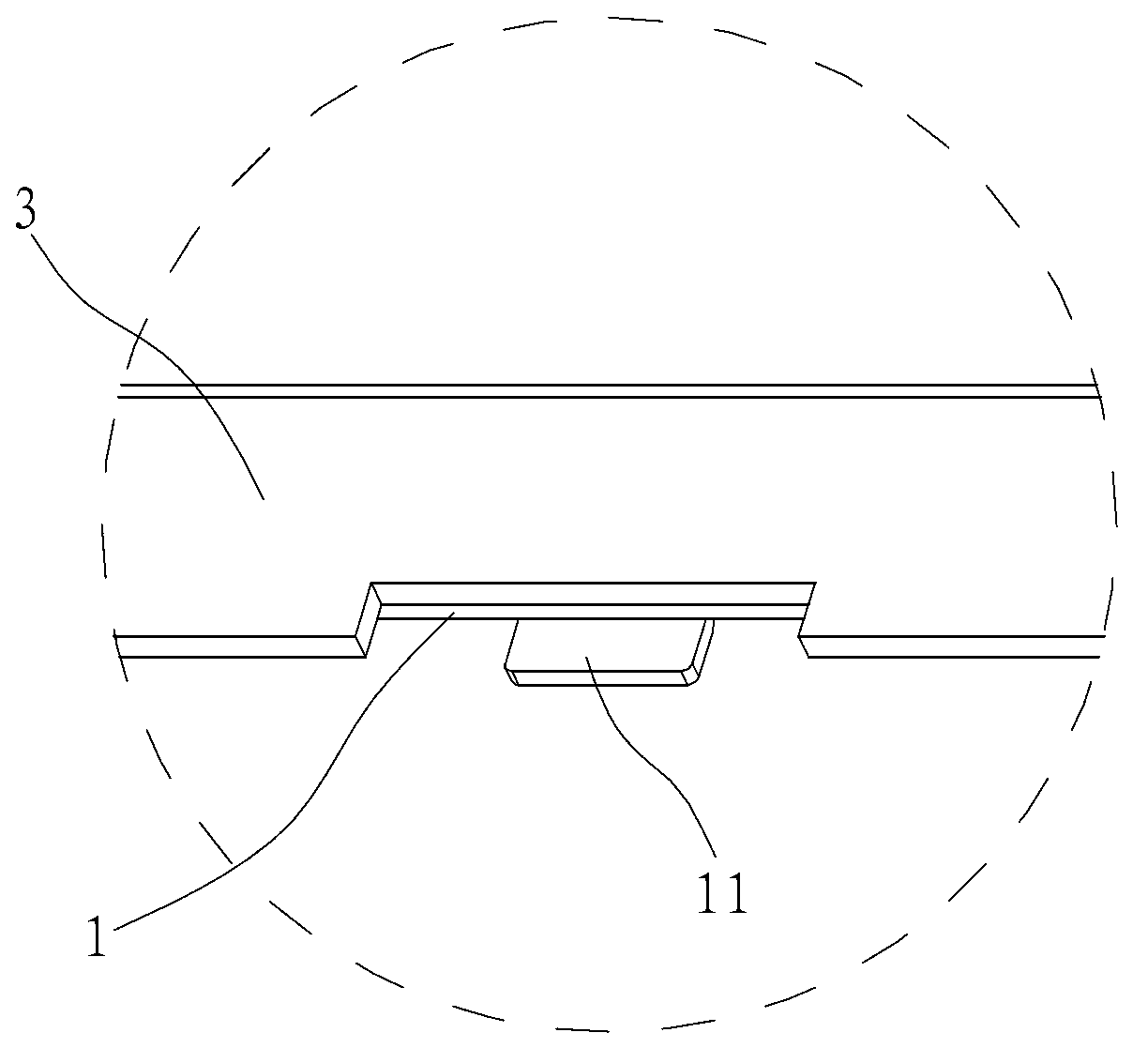

[0044] combine figure 1 and figure 2 , a diaphragm positioning structure, including a back plate, a positioning member 1, and a diaphragm 2, the positioning member 1 is attached to the inner end surface of the vertical edge 3 of the back plate, the positioning member 1 has a raised portion 11, and the membrane The sheet 2 has a positioning hole 21 adapted to the raised portion 11 , and the diaphragm 2 is positioned through the positioning hole 21 in cooperation with the raised portion 11 .

Embodiment 2

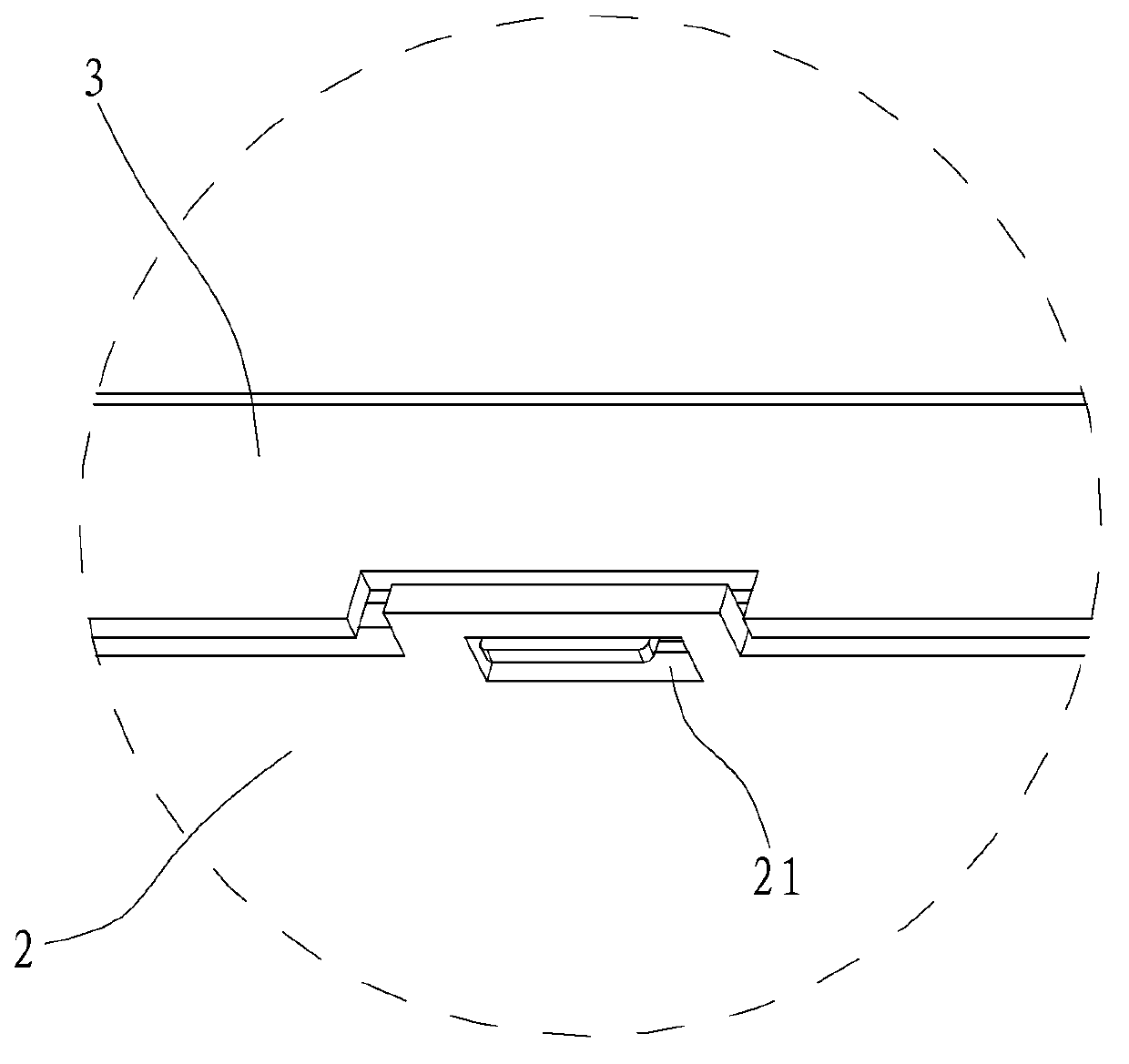

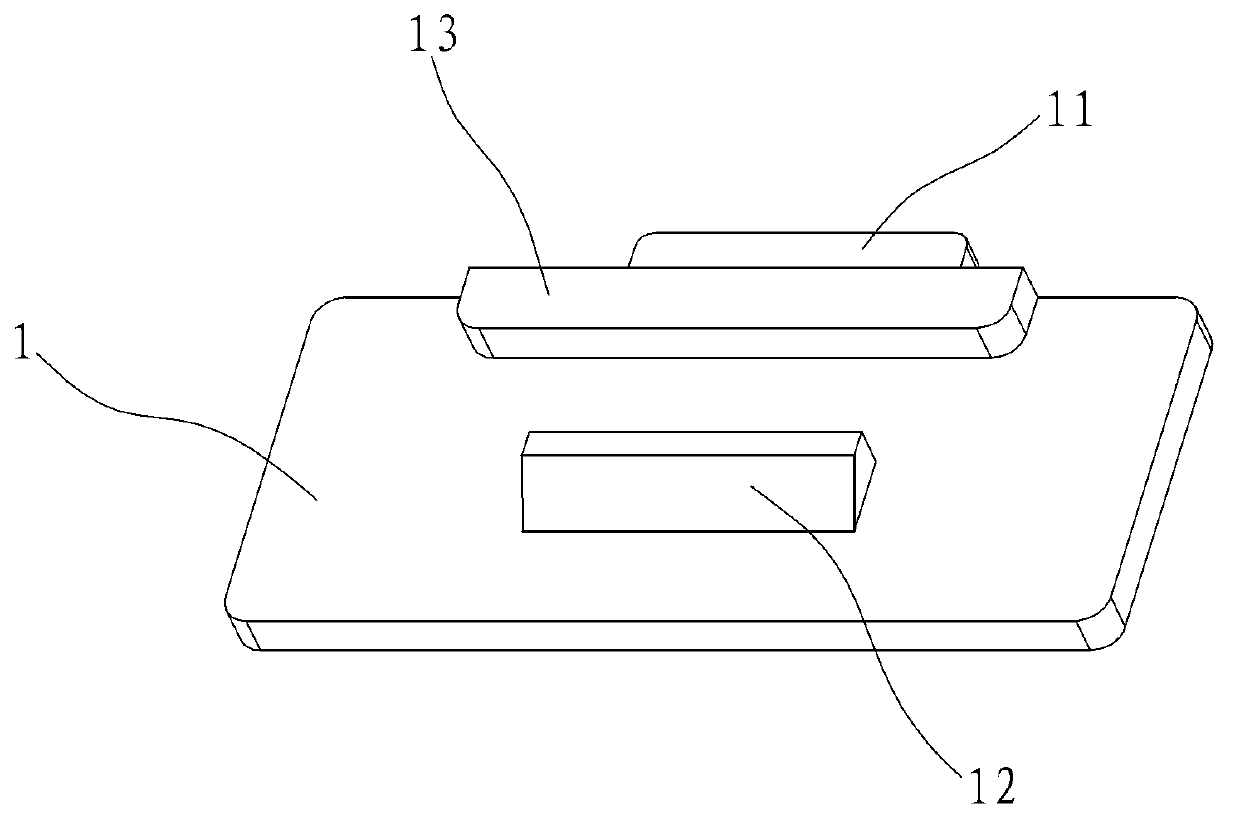

[0046] combine Figure 3 to Figure 5 , a diaphragm positioning structure, including a back plate, a positioning member 1, and a diaphragm 2, the positioning member 1 is attached to the inner end surface of the vertical edge 3 of the back plate, the positioning member 1 has a raised portion 11, and the membrane The sheet 2 has a positioning hole 21 adapted to the raised portion 11 , and the diaphragm 2 is positioned through the positioning hole 21 in cooperation with the raised portion 11 .

[0047] The positioning member 1 is provided with a buckle 12, and the vertical edge 3 of the backboard is provided with a slot 32 that is compatible with the buckle 12; the positioning member 1 is provided with a positioning rib 13, and the edge of the backboard The vertical edge 3 is provided with a positioning groove 33 adapted to the positioning rib 13 .

[0048] Or, according to the needs of actual assembly, a card slot can also be provided on the positioning member 1, and a buckle ma...

Embodiment 3

[0050] combine Figure 6 to Figure 9 , a diaphragm positioning structure, including a back plate, a positioning member 1, and a diaphragm 2, the positioning member 1 is attached to the inner end surface of the vertical edge 3 of the back plate, the positioning member 1 has a raised portion 11, and the membrane The sheet 2 has a positioning hole 21 adapted to the raised portion 11 , and the diaphragm 2 is positioned through the positioning hole 21 in cooperation with the raised portion 11 .

[0051]The positioning member 1 is provided with a buckle 12, and the vertical edge 3 of the backboard is provided with a slot 32 that is compatible with the buckle 12; the positioning member 1 is provided with a positioning rib 13, and the edge of the backboard The vertical edge 3 is provided with a positioning groove 33 adapted to the positioning rib 13 .

[0052] The positioning part 1 is also equipped with a bracket 4, and a positioning part is formed between the vertical edge 3 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com