Online detection device of clear water layer thickness of concentration tank

A technology of detection device and clear water layer, applied in measurement devices, instruments, etc., can solve the problems of restricting the development of automatic control technology in the concentration process, high labor intensity, poor safety, etc., achieving fast calculation speed, simple mathematical model, control Timely and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

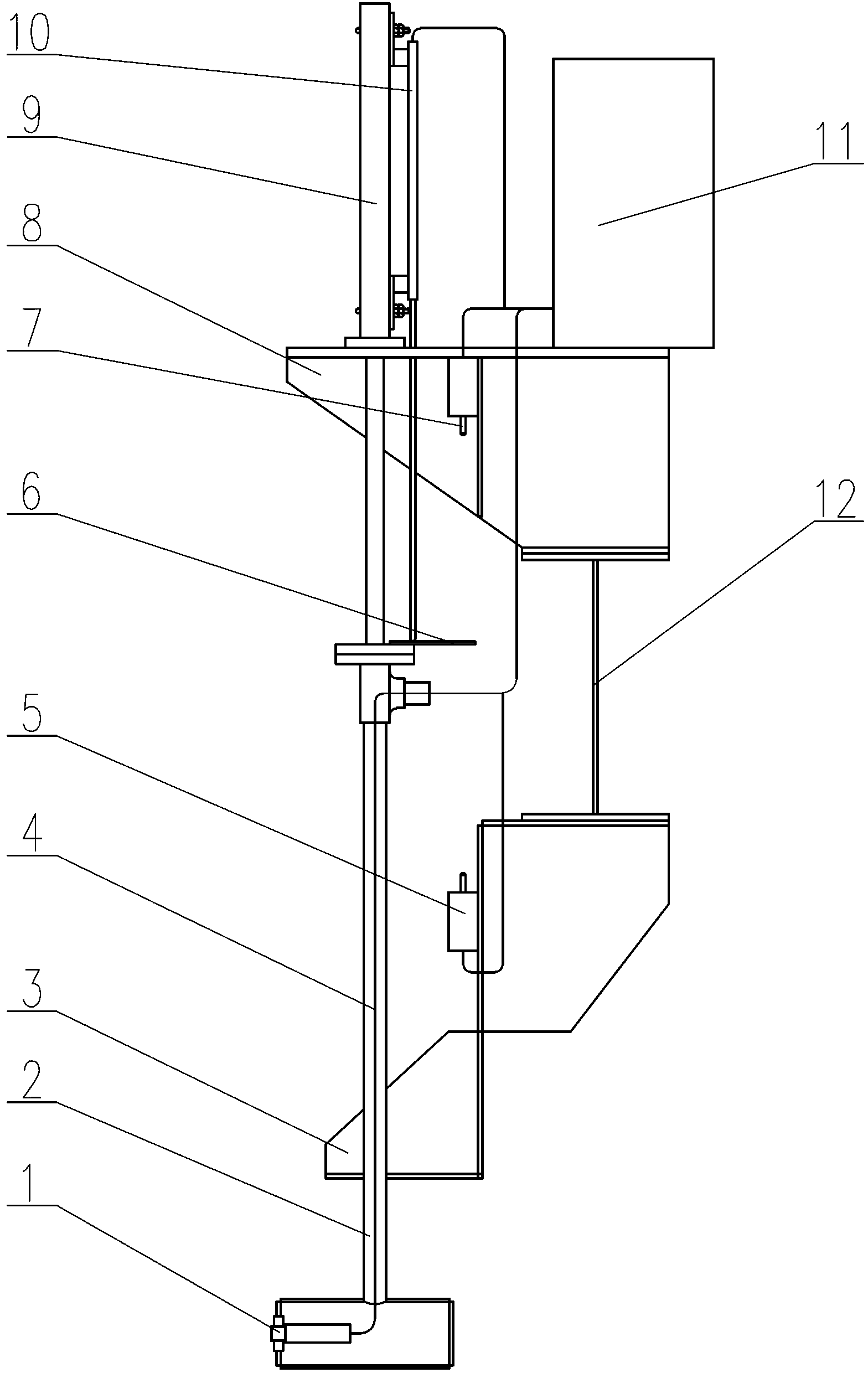

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] As shown in the drawings, the present invention includes a probe rod 2, a pressure sensor 1, a guide seat 3, a support 8, a lifting device 9, a displacement sensor 10, a PLC control box 11, an upstroke switch 7, a downstroke switch 5, and the like.

[0015] The support 8 and the guide seat 3 are installed on the concentrator bridge 12, the lifting device 9 and the upper travel switch 7 are installed on the support 8, and the lower travel switch 5 is installed on the guide seat 3; the side of the lifting device 9 is fixed with a displacement sensor 10 , the lower part is connected to the probe rod 2; the probe rod 2 is a hollow airtight structure, the lower part is equipped with a pressure sensor 1, and the probe of the pressure sensor 1 is in contact with the liquid surface; the guide seat 3 guides the up and down movement of the probe rod 2; The limit plate 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com