Testing table for testing of forklift transmission part

A technology of transmission components and test benches, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of fixed structure and inability to adapt to various transmission components, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

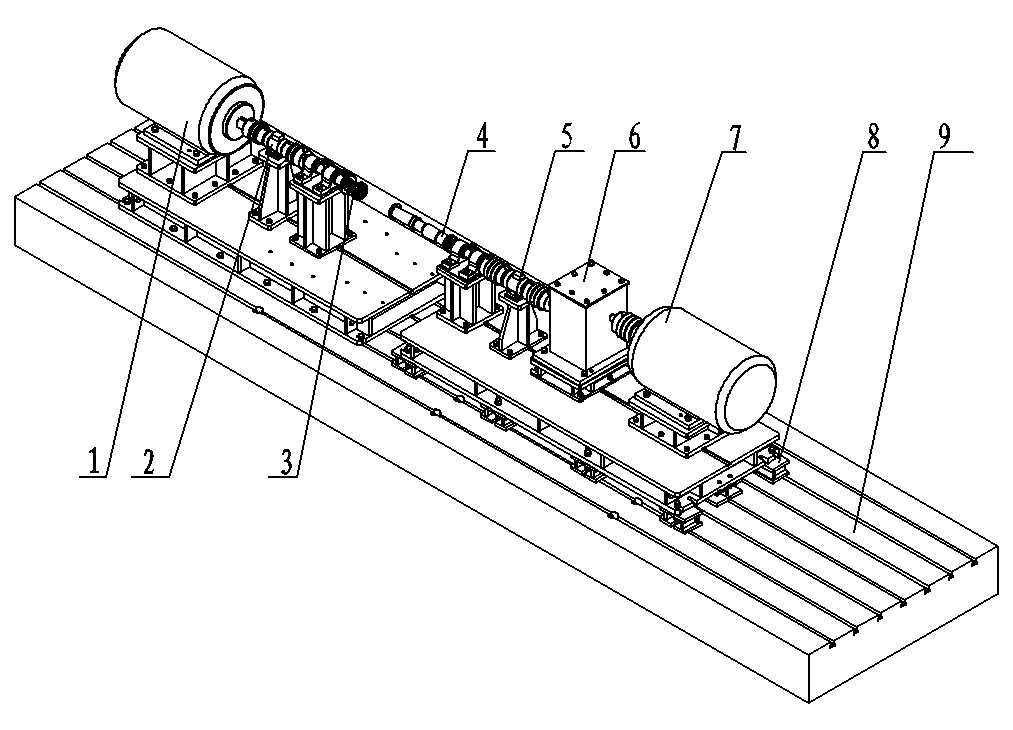

[0024] Such as figure 1 As shown, the test bench used for the test of forklift transmission components includes a strip-shaped cast iron bottom plate 9, and seven longitudinal T-shaped installation slots are evenly distributed on its top surface, of which the middle three are positioning slots; it also includes a drive bench and a load The platform, the driving platform and the load platform are installed and installed and positioned on the cast iron base plate 9 through a T-shaped installation groove, so that the relative positions of the two can be adjusted conveniently, and the two are longitudinally distributed and corresponding to the cast iron base plate.

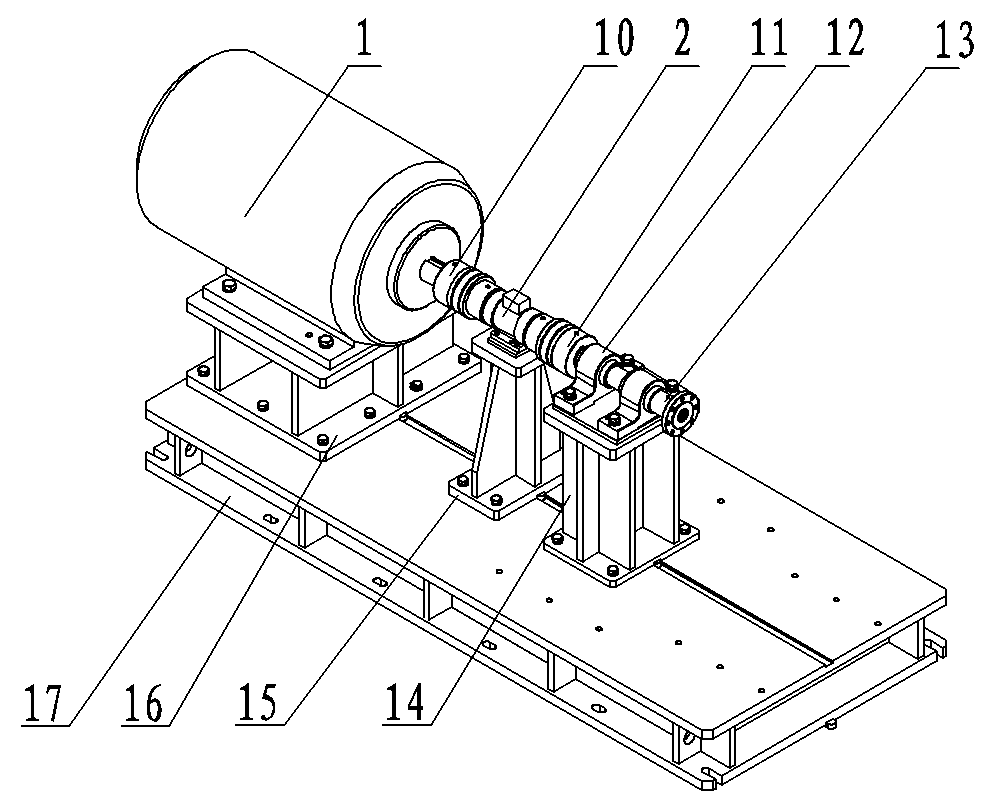

[0025] Such as figure 2 As shown, the drive stand includes a drive transmission chain and a drive base plate 17, the top surface of the drive base plate 17 is provided with a positioning groove, and the bottom surface is equipped with a positioning key matched with the positioning groove of the cast iron base plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com