secateurs

A technology of pruning machine and driving motor, applied in the field of pruning machine, can solve the problems of blade burr, less than ideal, limited shear force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

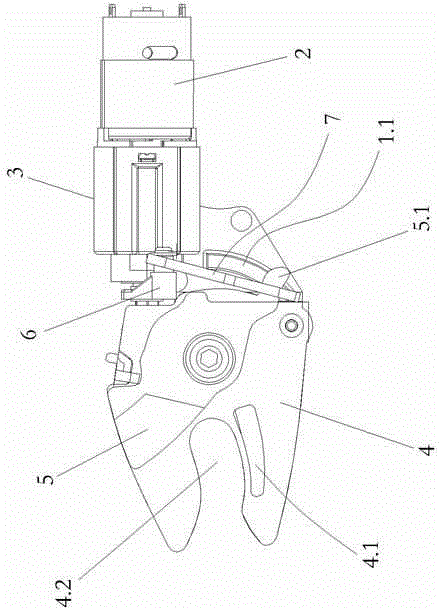

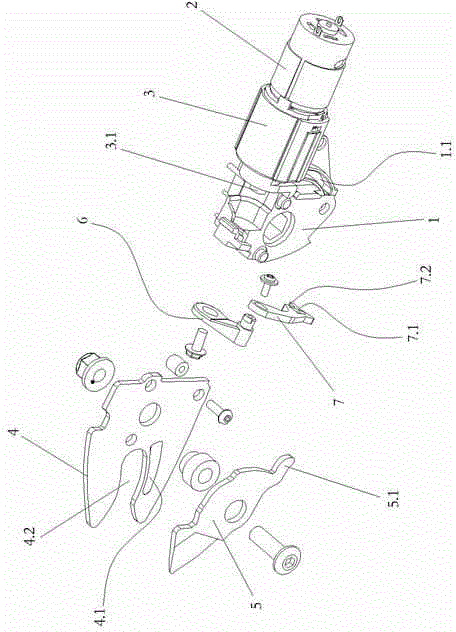

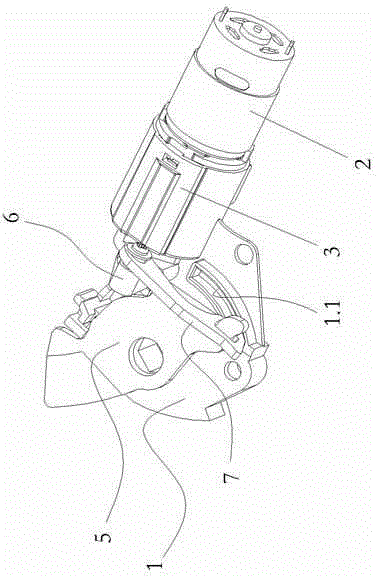

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, pruning machine of the present invention, it comprises support 1, is provided with driving motor 2, reduction box 3, static blade 4 and moving blade 5 on support 1, driving motor 2 is assembled with reduction box 3 and is connected, and moving blade 5 is connected with static The blade 4 is hingedly fitted, and the blade surface of the movable blade 5 close to the static blade 4 is attached to the blade surface of the static blade 4 close to the movable blade 5 .

[0015] The pruning machine also includes a fork 6 and a connecting piece 7, the fork 6 is connected and fixed with the output shaft 3.1 of the reduction box 3, the front end of the connecting piece 7 is hinged with the fork 6, and the rear end is movably connected with the moving blade 5; 4 At least one first edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com