Optical device coupling device

A technology of coupling device and optical device, which is applied to the coupling of optical waveguides, etc., can solve the problems of unqualified product performance, displacement, and inability to guarantee product electrical performance parameters, and achieve the effect of ensuring accuracy and coupling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

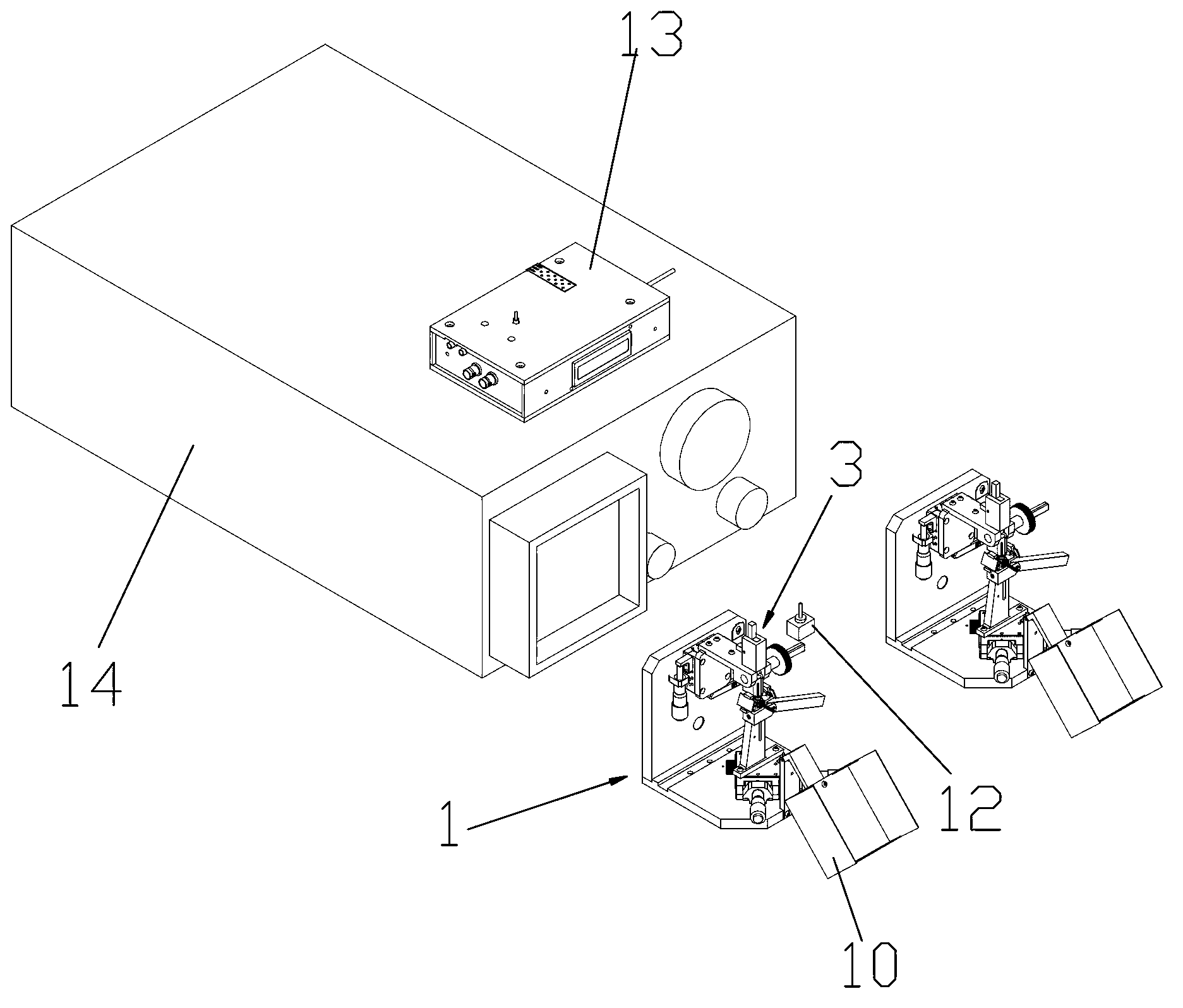

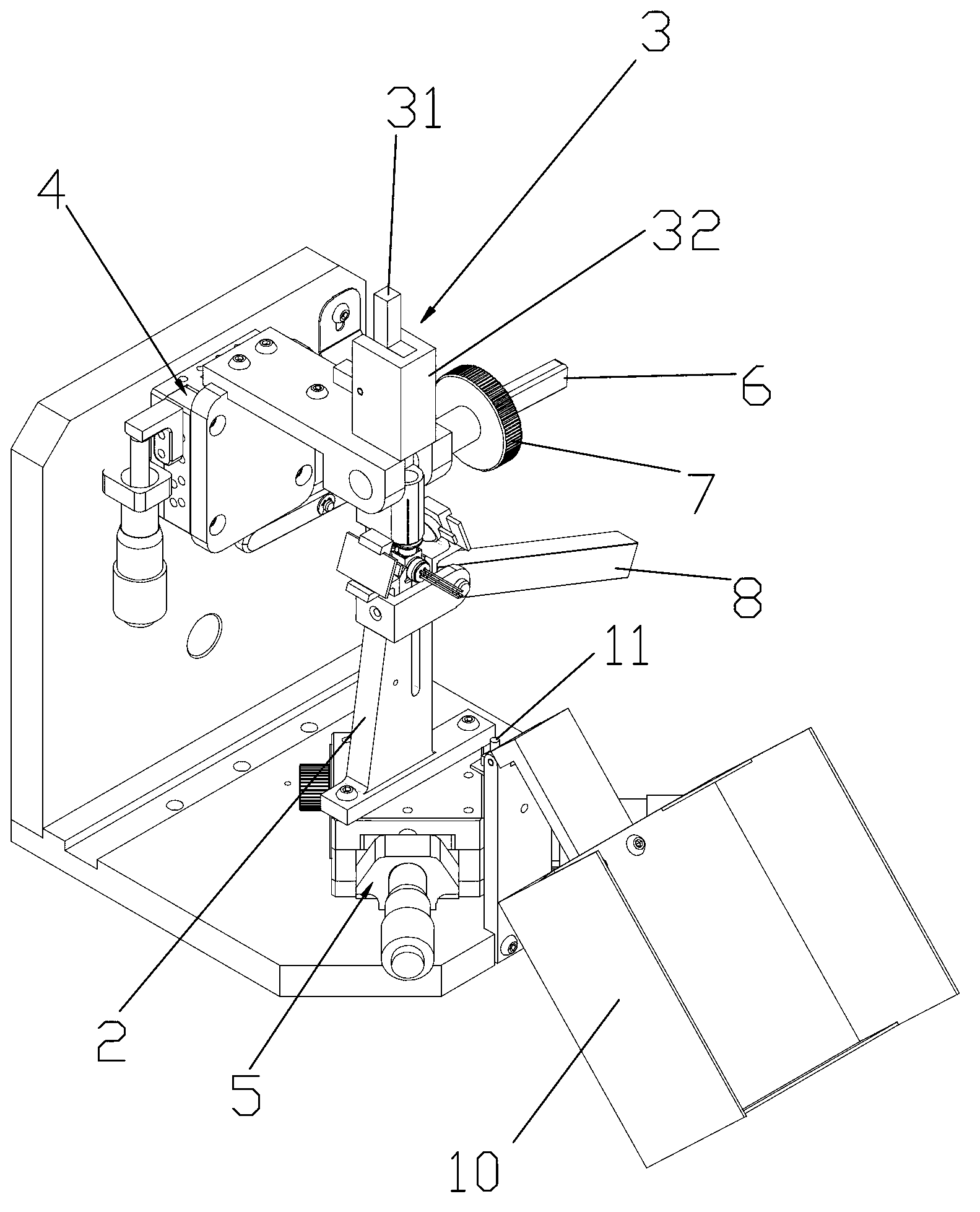

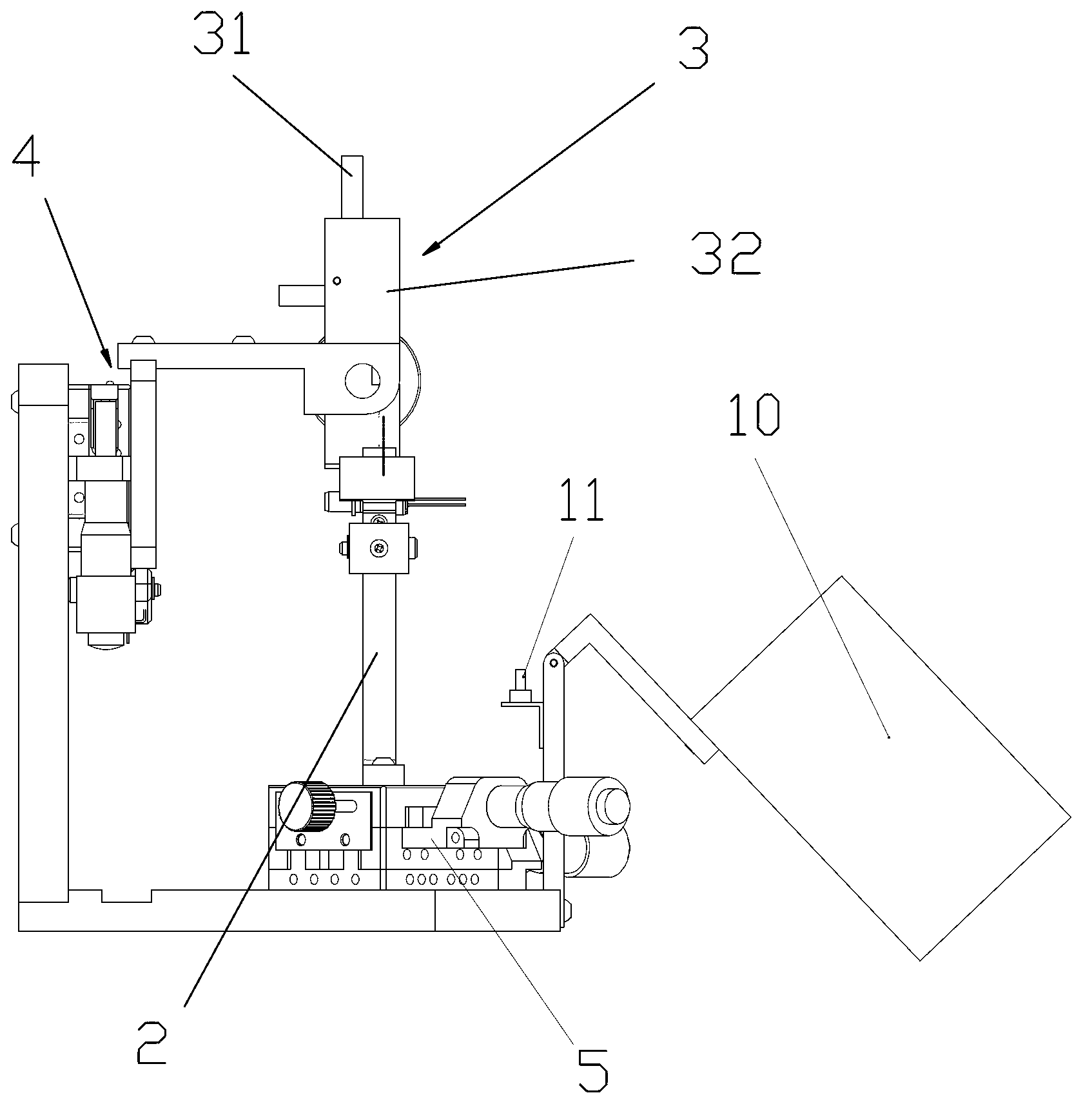

[0030] As shown in the figure, an optical device coupling device disclosed by the present invention includes two coupling fixtures 1, and the coupling fixture 1 includes a base clamp 2, a material return device 3, a fine-tuning frame A4, and a fine-tuning frame B5, through which the fine-tuning frame A4 and The fine-tuning frame B5 adjusts the positions of the stripping device 3 and the base clamp 2, and couples the response voltage signal to dispensing and baking the glue to fix it when it is enlarged.

[0031] The base clamp 2 is arranged on the fine-tuning frame B5, and is used for clamping the semi-finished base. The stripping device 3 is arranged on the fine-tuning frame A4, and comprises stripping bar 31, socket block 32, and stripping bar 31 can move in socket block 32, and the bottom of stripping bar 31 is provided with tube core 91 hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com