Cooling and purifying system of spent fuel pool

A technology of spent fuel pool and purification system, applied in the field of spent fuel pool cooling and purification system, can solve problems such as endangering the safety of stored fuel, loss of coolant, and excessive equipment, so as to improve safety and economy, and reduce the loss of cooling. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

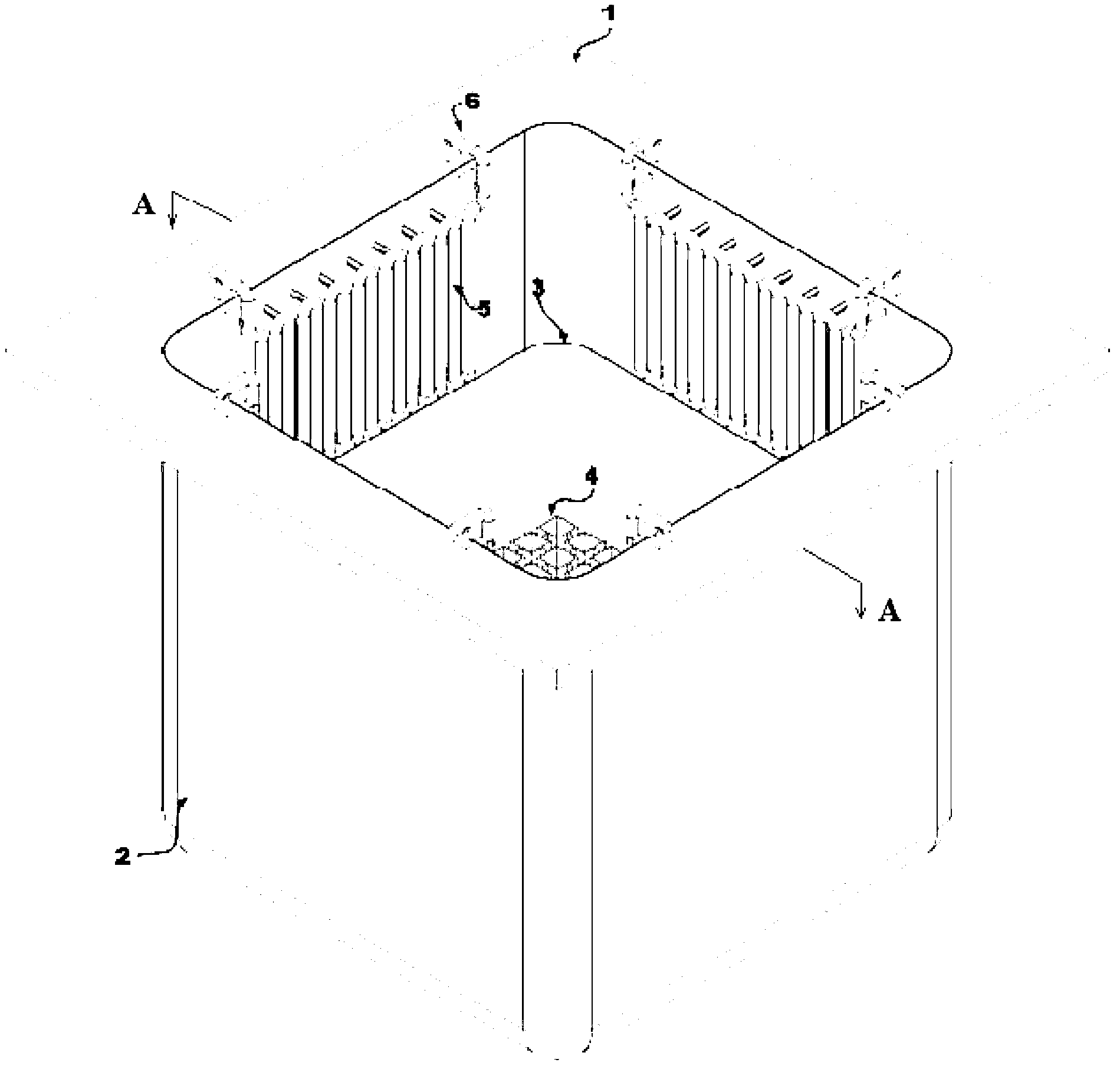

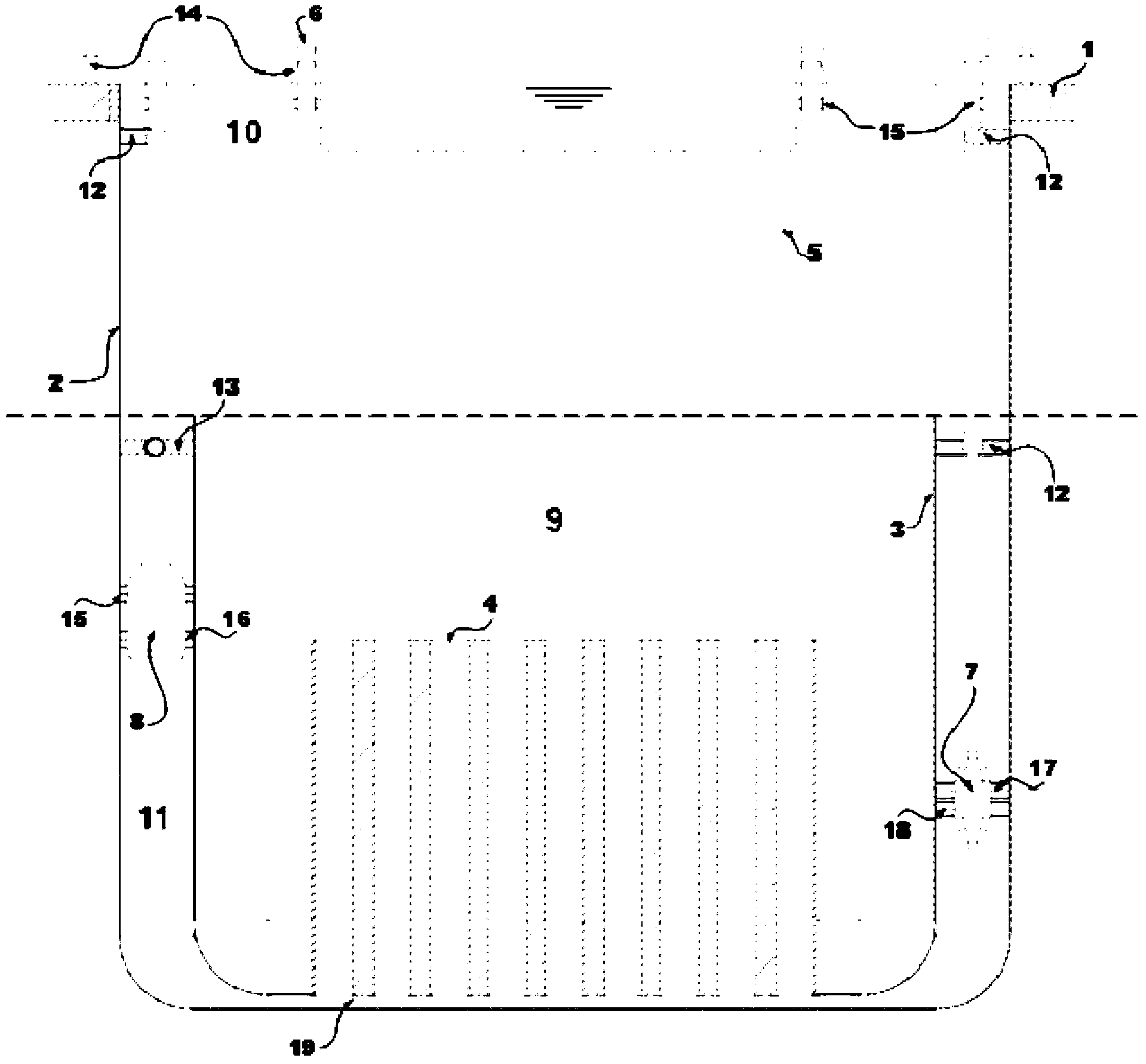

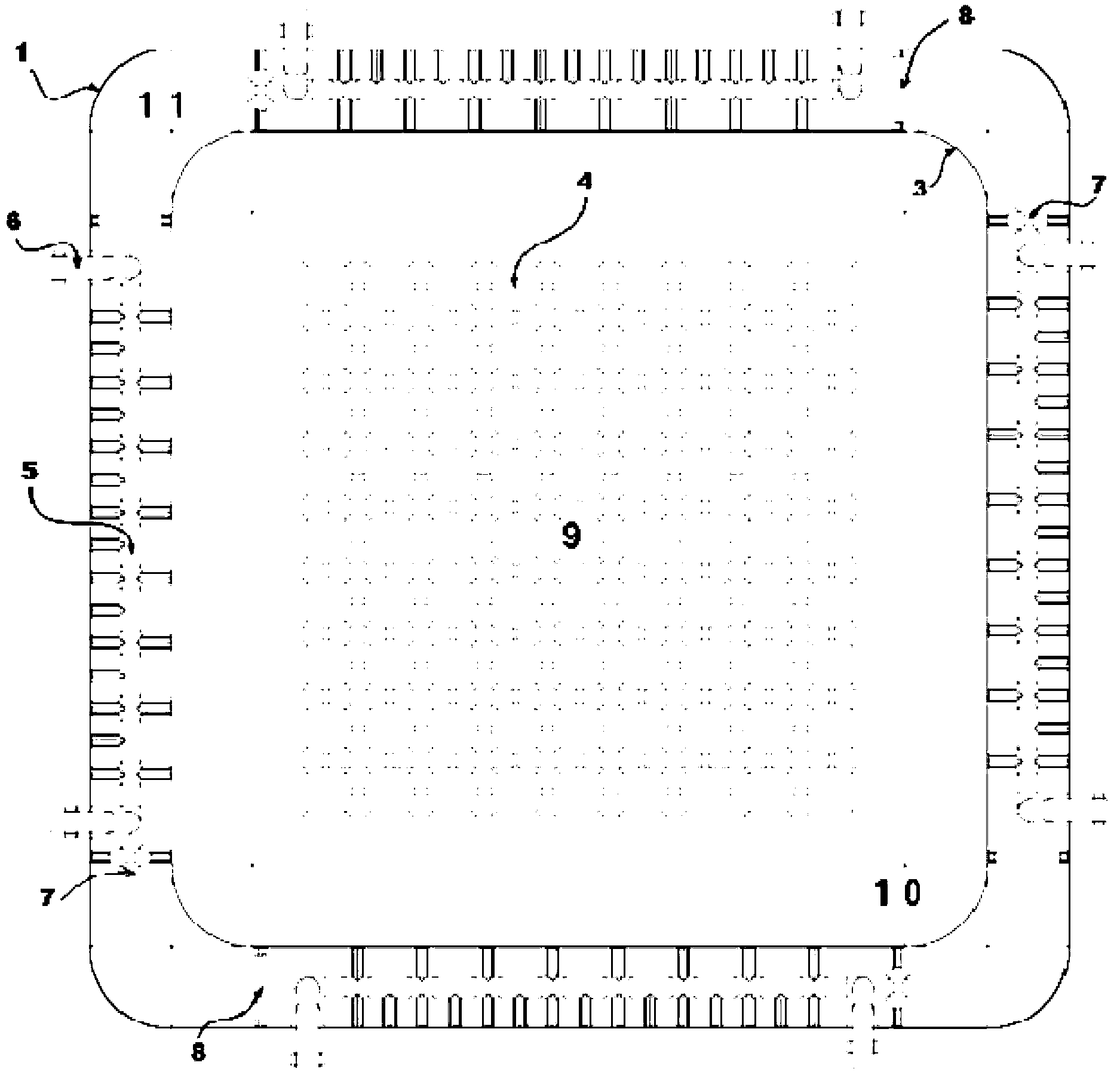

[0022] Such as Figure 1-4 As shown, a spent fuel pool cooling and purification system provided by the present invention is set in the spent fuel pool, and all major equipment is located below the operating plane 1. The system includes a cooling structure 5 located on the upper part of the spent fuel pool, and the cooling The structure 5 is parallel to the vertical direction of the pool wall.

[0023] Such as figure 2 As shown, the inner wall of the spent fuel pool is coated with a metal surface, and the metal surface 2 of the pool wall forms a cubic water body container as a whole. The cooling structure 5 is distributed around the upper part of the water body container and supported by the supporting structures 12, 13, 14.

[0024] The cooling structure 5 can be formed by a plurality of U-shaped cooling pipes arranged side by side in series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com