A pulse power supply control system for electrostatic dust removal

A pulsed power supply and control system technology, applied in the field of electrostatic precipitators, can solve problems such as slow dynamic response speed, power consumption, and inability to adjust output voltage immediately, achieve fast recovery of electric field energy, reduce volume and weight, and overcome back corona live effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

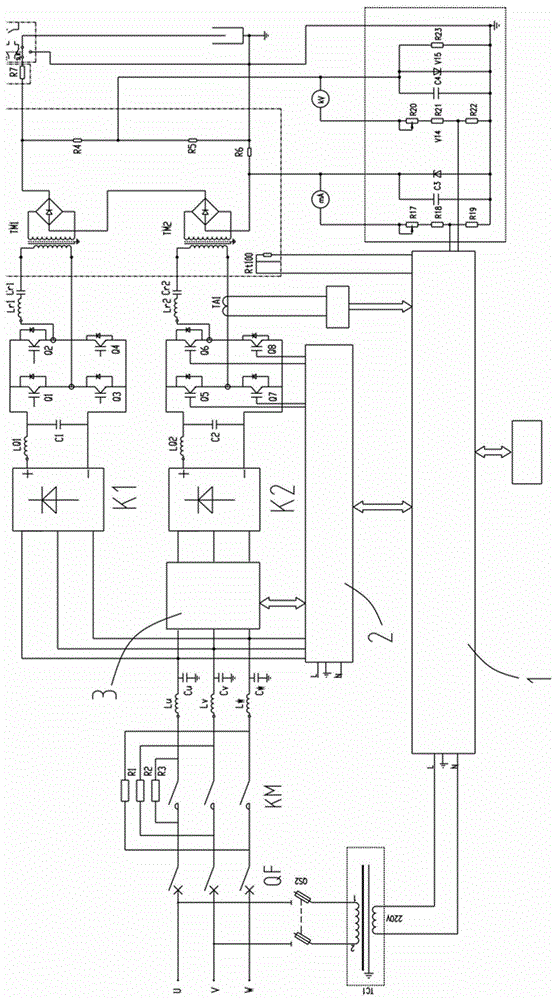

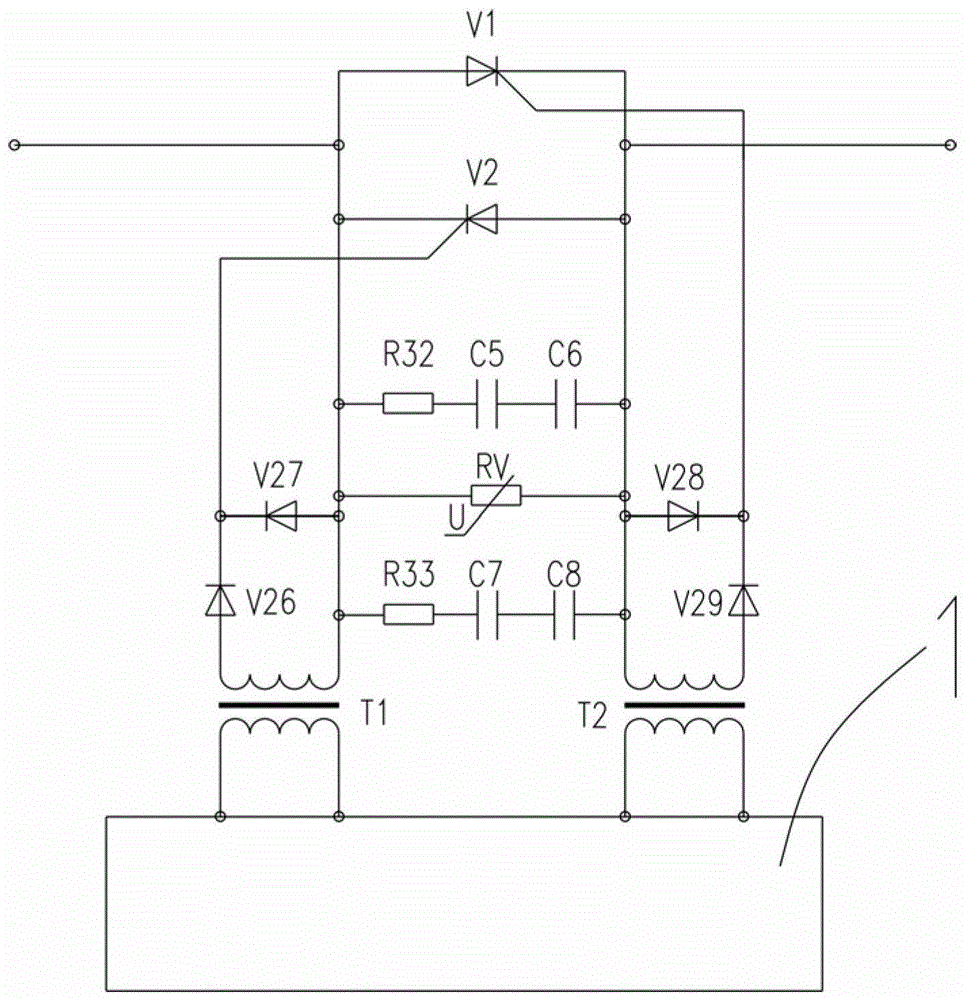

[0017] Such as Figure 1-2 As shown, an electrostatic precipitator pulse power supply control system includes a main circuit, a controller and a trigger drive sampling circuit. The main circuit includes a first circuit that provides a continuous fundamental wave voltage to the dust collector and a discontinuous voltage to the dust collector. The second loop of the pulse voltage; the controller controls the fundamental voltage to be lower than the full breakdown voltage of the spark discharge inside the electric field of the dust collector, and the controller controls the high-current pulse voltage to be three times the fundamental voltage and superimposed on the fundamental vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com