Integral advancing scraping and rolling compound cutter for flexibly boring, scraping and rolling

A composite tool, flexible technology, applied in the direction of tools, boring heads, manufacturing tools, etc. for lathes, can solve the problems of low work efficiency, affecting the finish, time-consuming and laborious, and achieve the effect of stable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

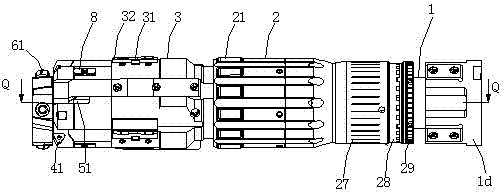

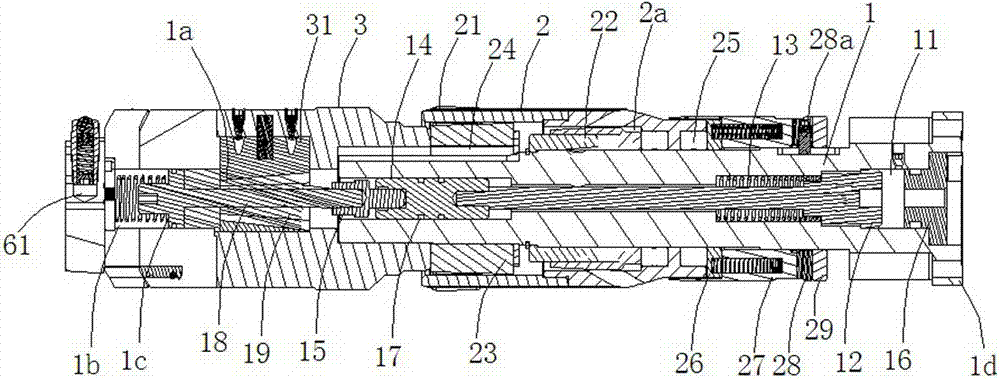

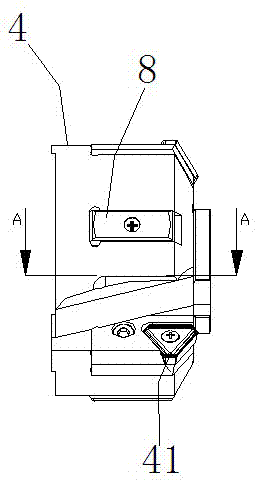

[0031] Figure 1 to Figure 11 Shown is the structural representation of the present invention.

[0032] The reference signs are: main shaft 1, first cavity 11, ejector rod 12, reverse spring 13, ball sleeve 14, ball head 15, plug 16, sealing ring 17, telescopic rod 18, inner telescopic support sleeve 19 , Outer telescopic support sleeve 1a, size adjustment device 1b, spring 1c, connection protrusion 1d, roller head 2, roller 21, telescopic mechanism 22, raceway 23, pin 24, guide support mechanism 25, support sleeve 26, adjustment Seat 27, adjusting chuck 28, designated pin 28a, locking ring 29, second cavity 2a, scraper head 3, scraper block 31, scraper blade 32, fine boring head 4, boring blade 41, two-in-one boring head 5 , boring tool block 51, floating boring head 6, floating head 61, floating mechanism sleeve 61a, guide ball 61b, flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com