Patents

Literature

43results about How to "High precision size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

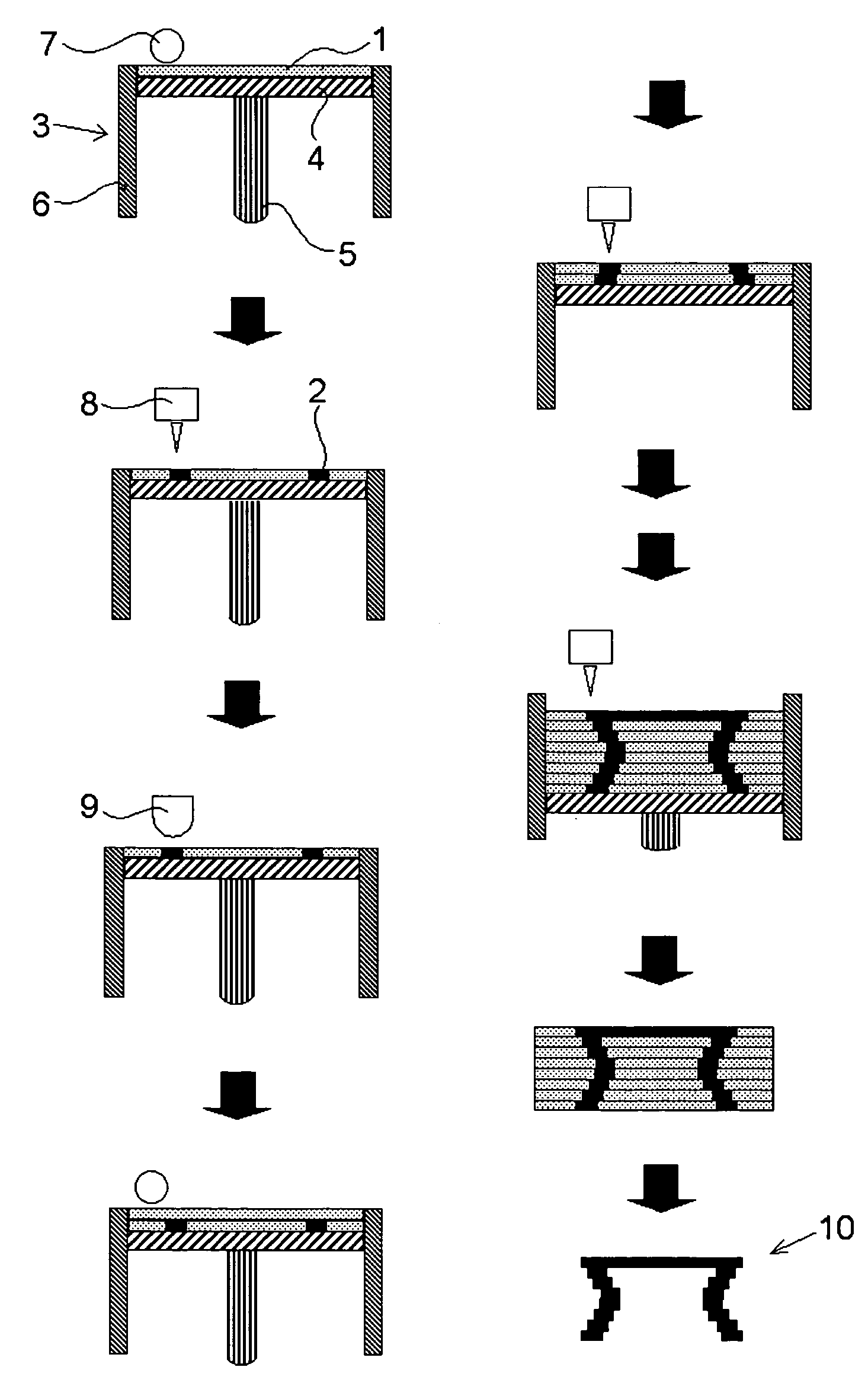

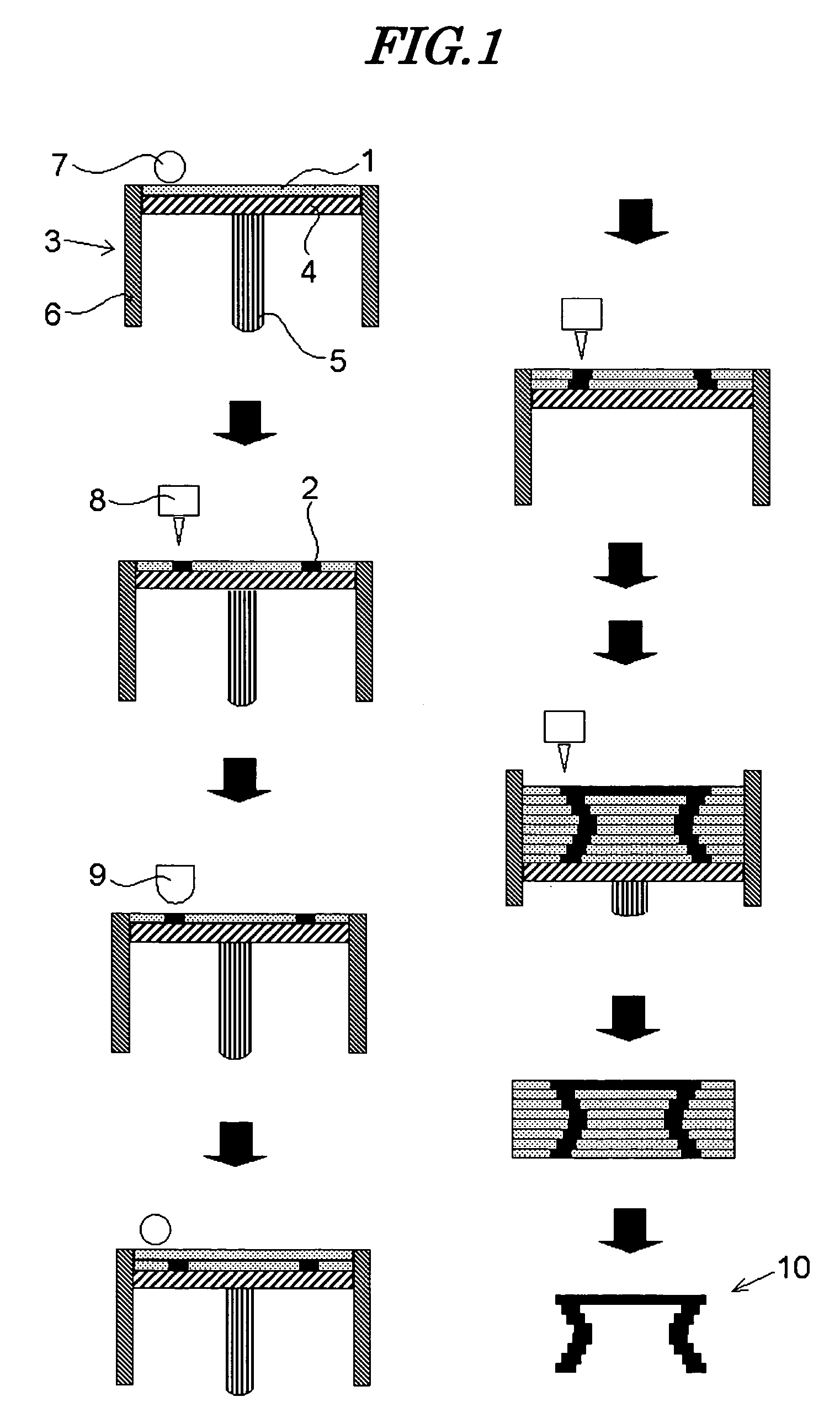

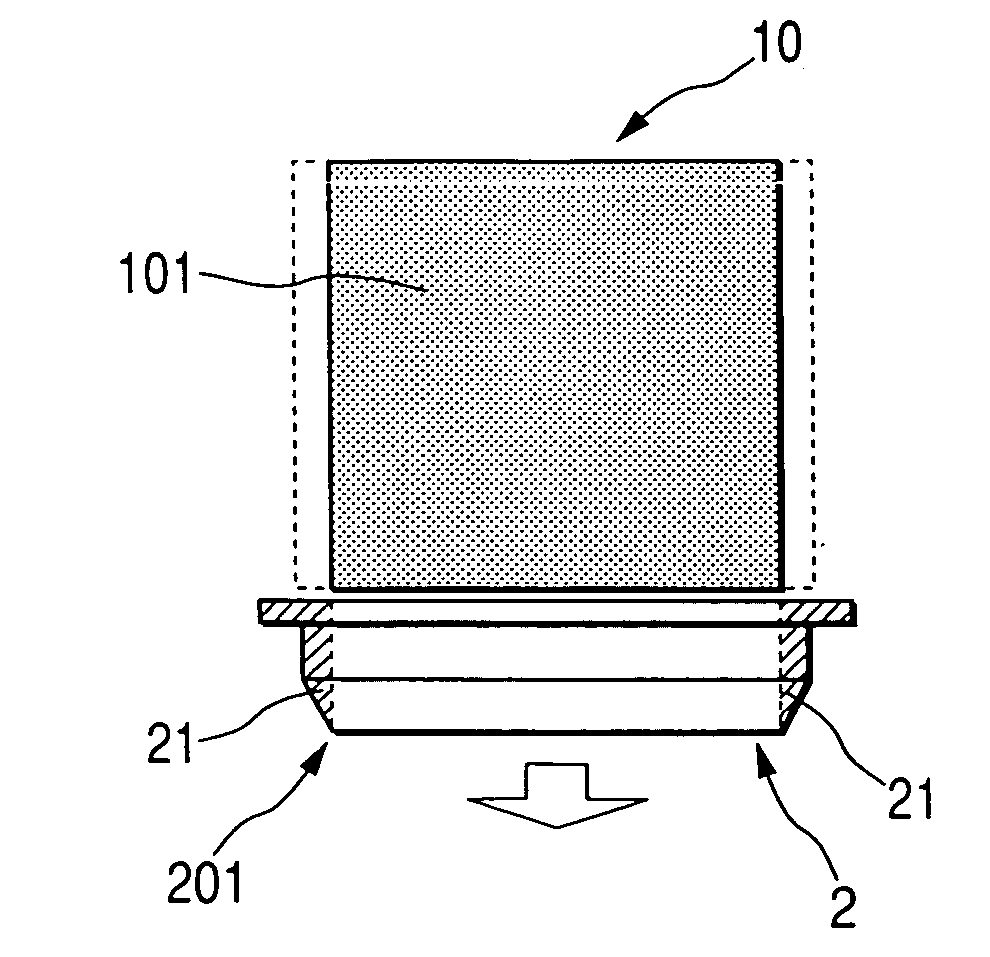

Process for producing three-dimensional model, and three-dimensional model

InactiveUS7300613B2Low costHigh strengthAdditive manufacturing apparatusCeramic shaping apparatusDimensional modelingShape formation

A process for producing a three-dimensional model is provided. The process includes a step (layer formation step) of forming a layer of a powder material, the layer having a predetermined thickness, a step (cross-sectional shape formation step) of imagewise bonding the powder material layer by a binder according to sliced cross-sectional data of a modeled object so as to give a cross-sectional shape, and sequentially repeating the above steps. The surface gloss of the three-dimensional model obtained when measured at 20° is 20% or more. Furthermore, production equipment used in the above process is provided. Moreover, a three-dimensional model is provided that contains a powder material and a binder and is formed by imagewise curing the binder, the three-dimensional model having a surface gloss when measured at 20° of 20% or more.

Owner:FUJIFILM CORP +1

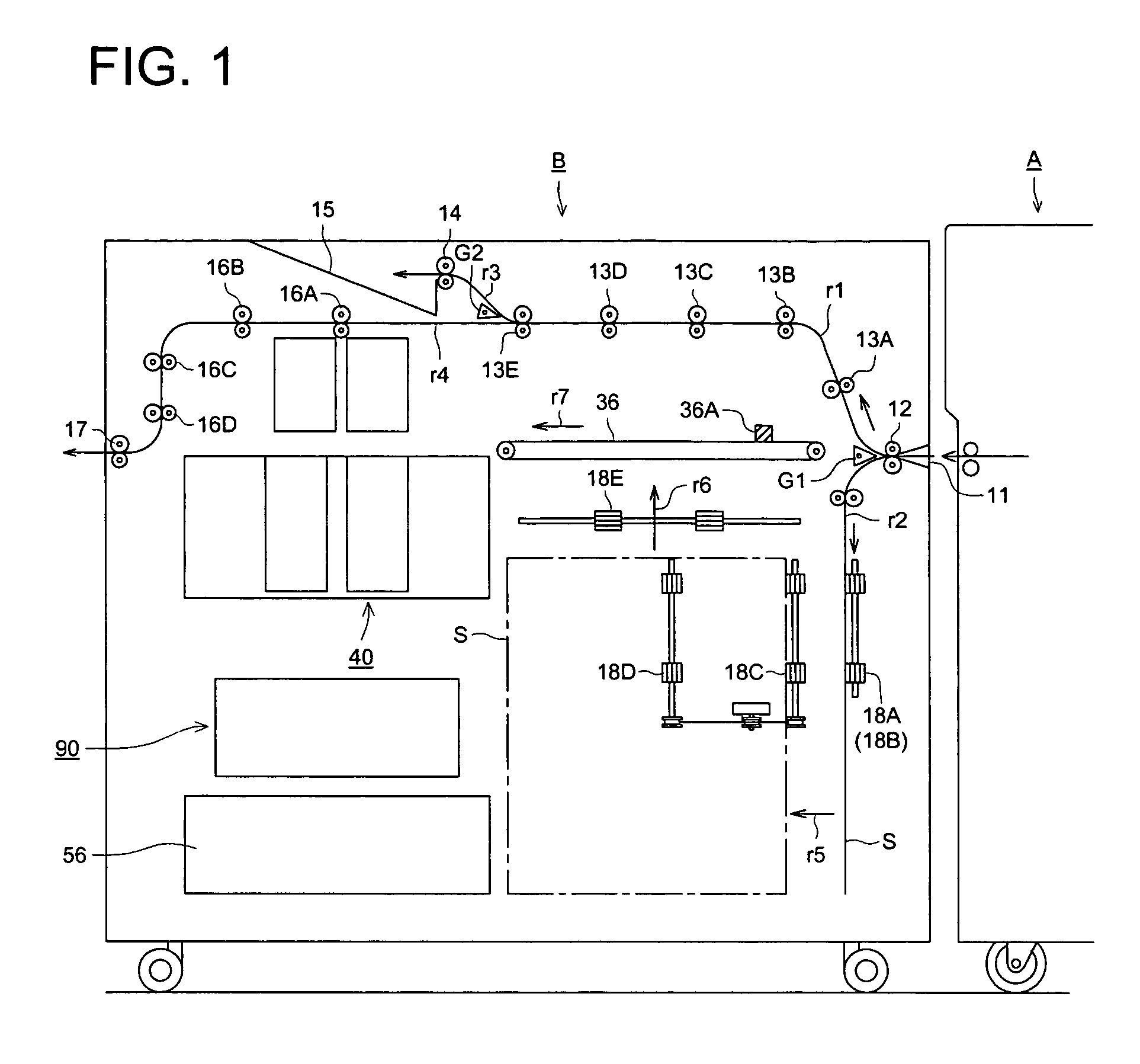

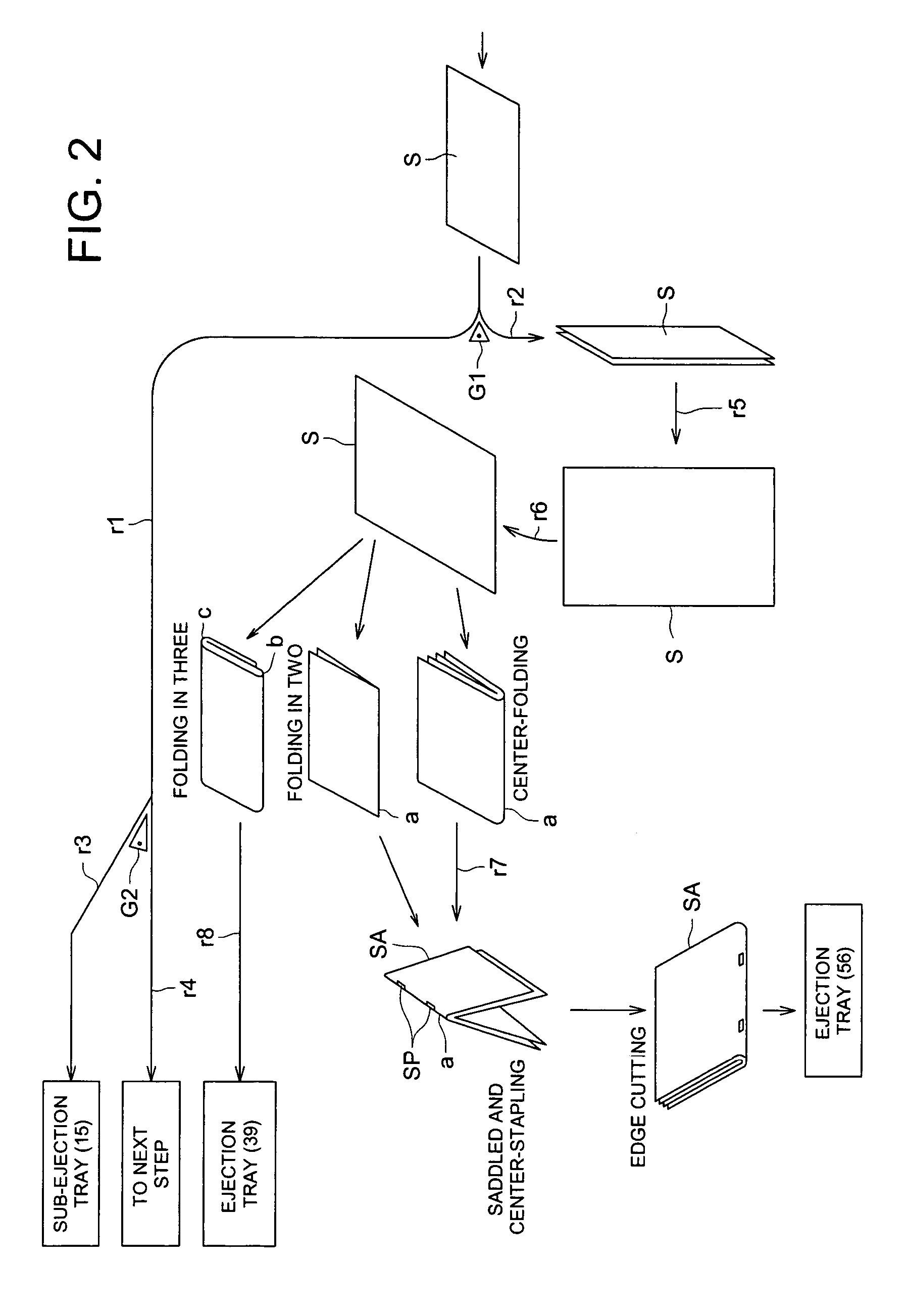

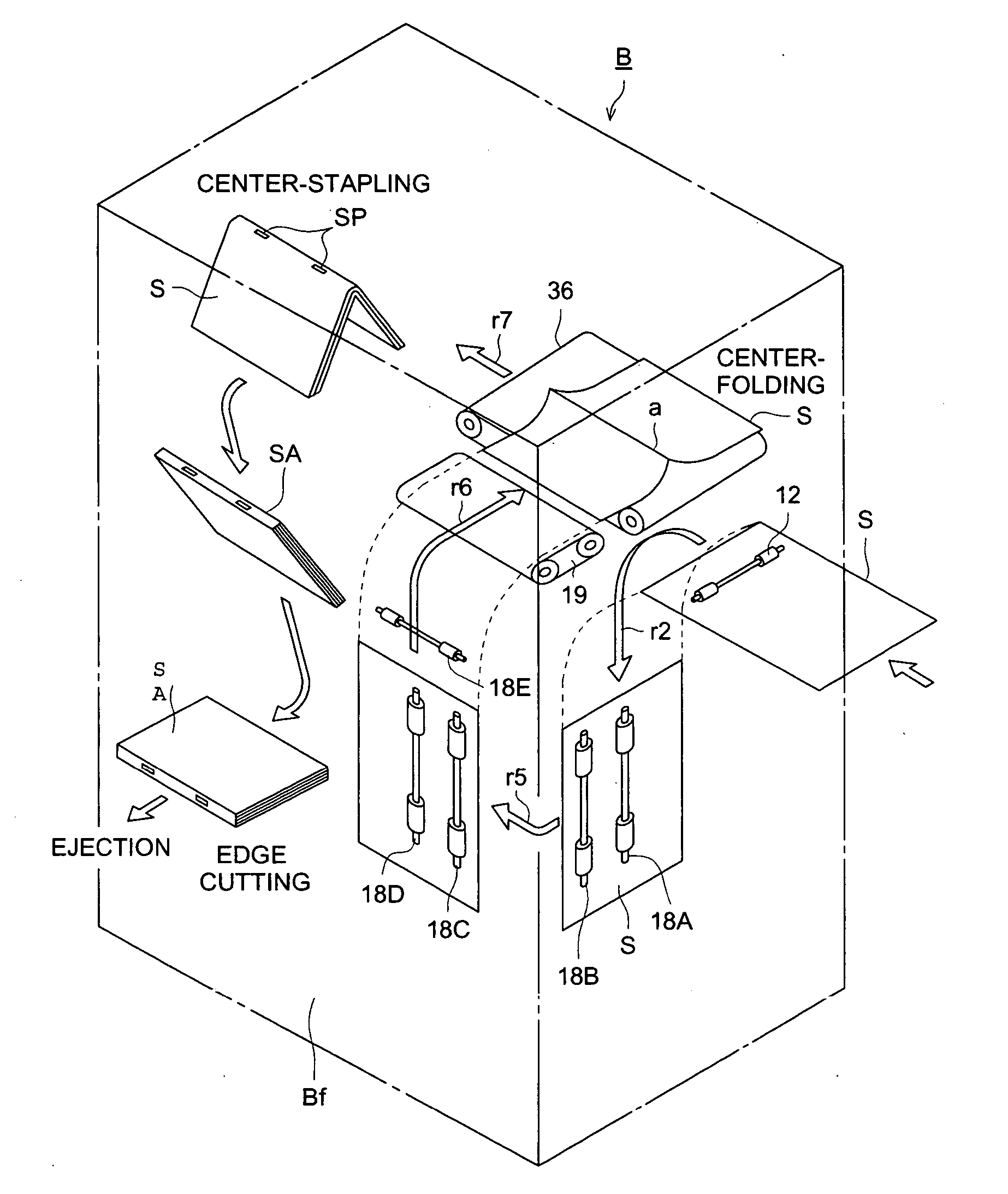

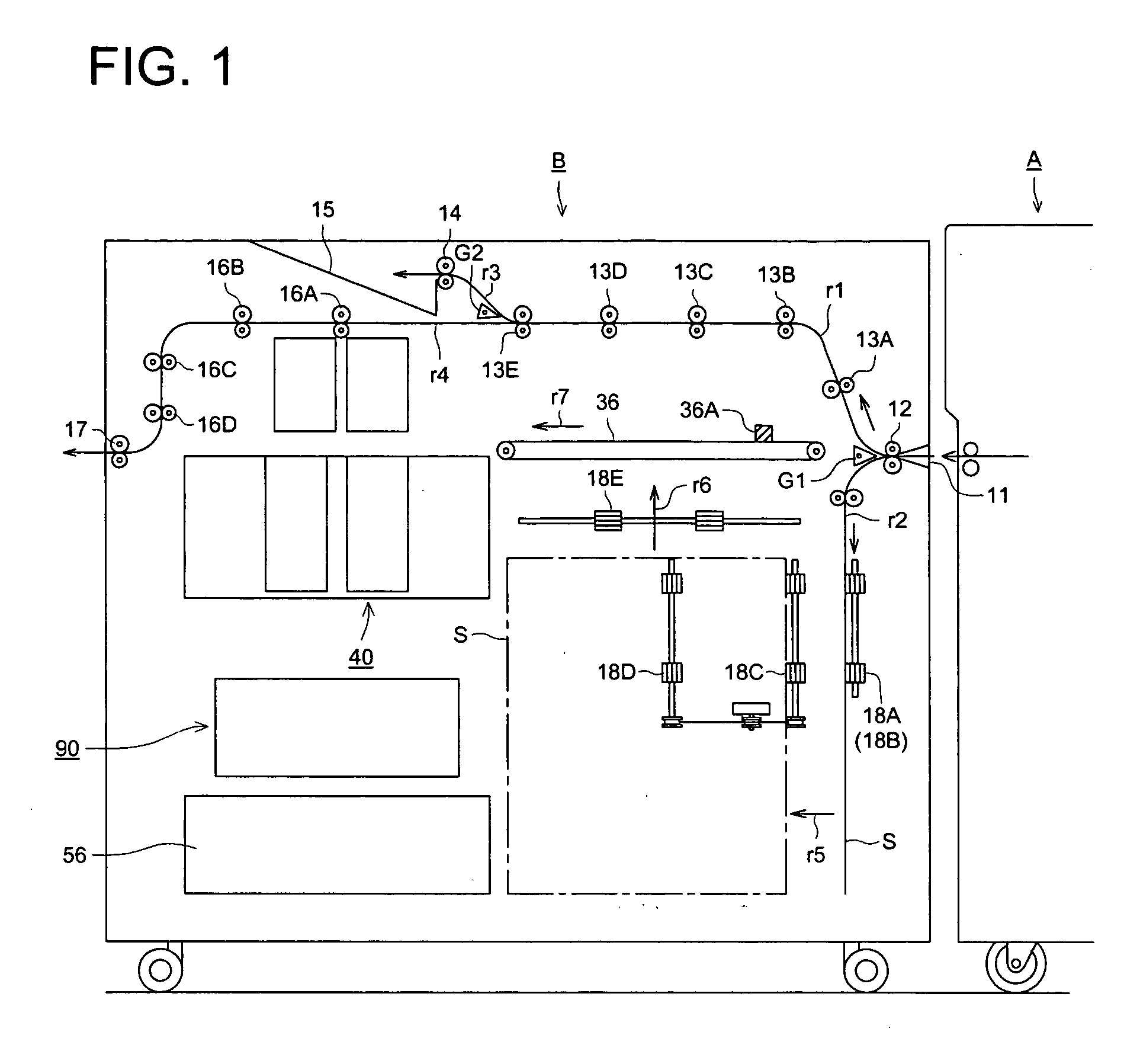

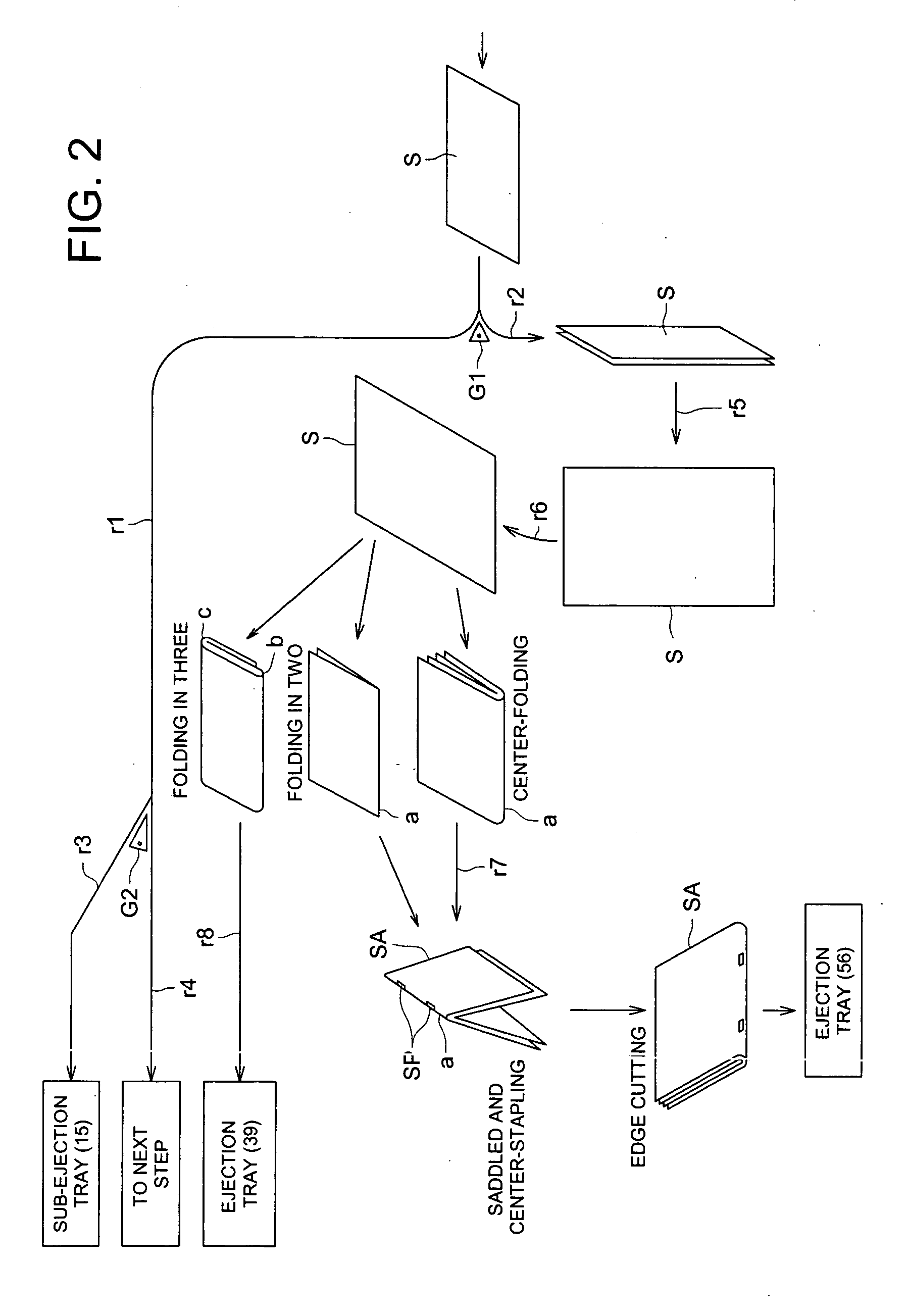

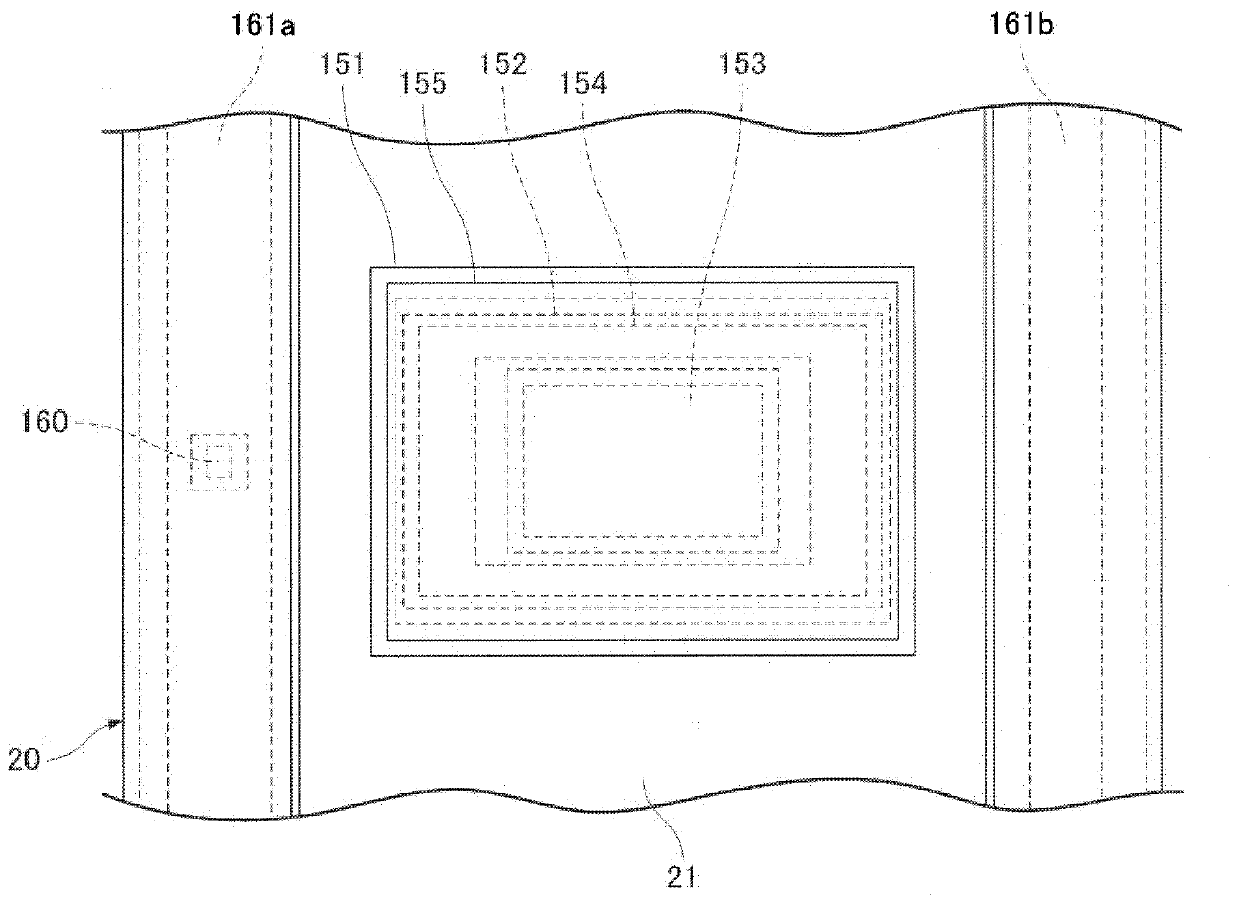

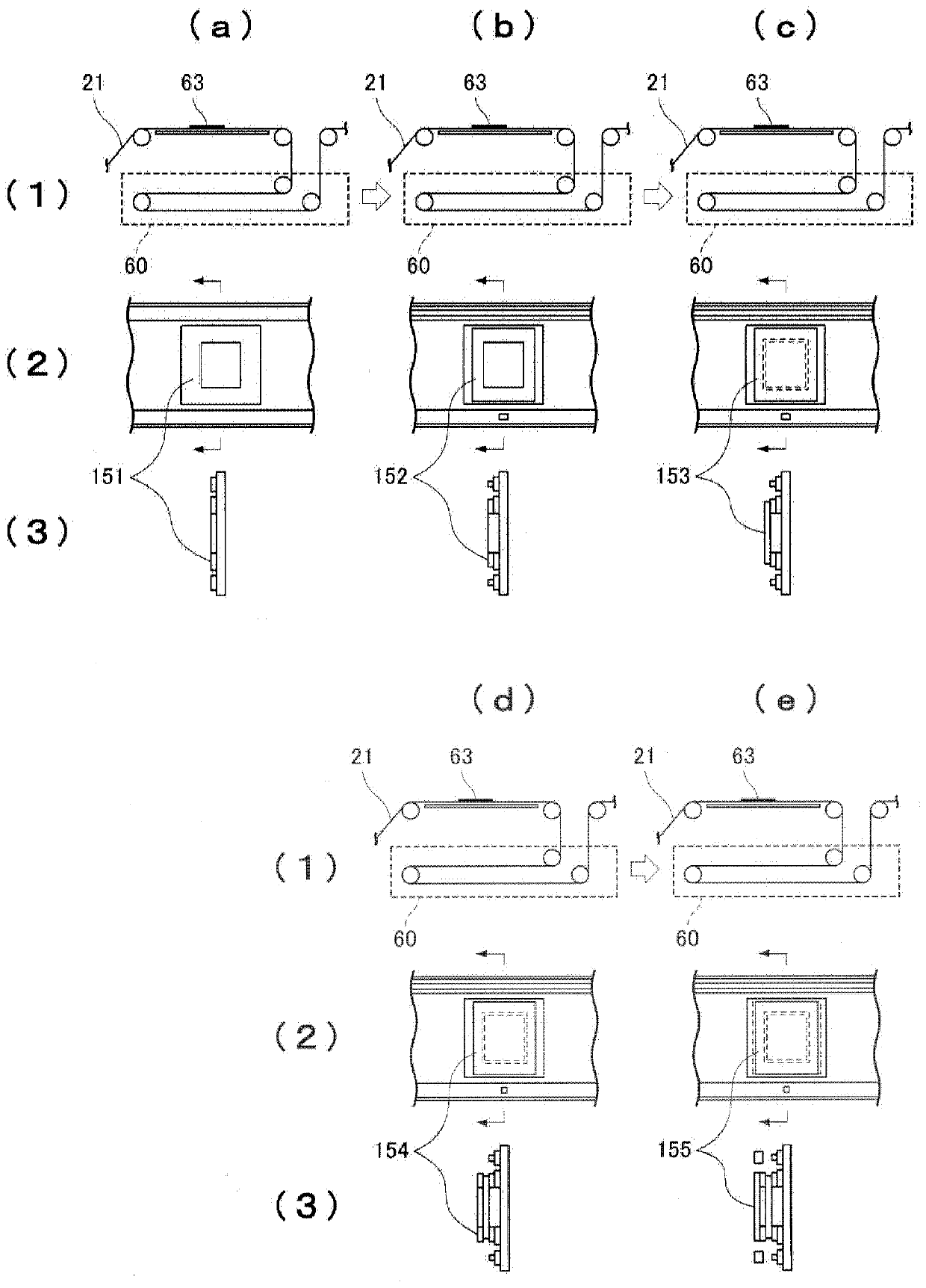

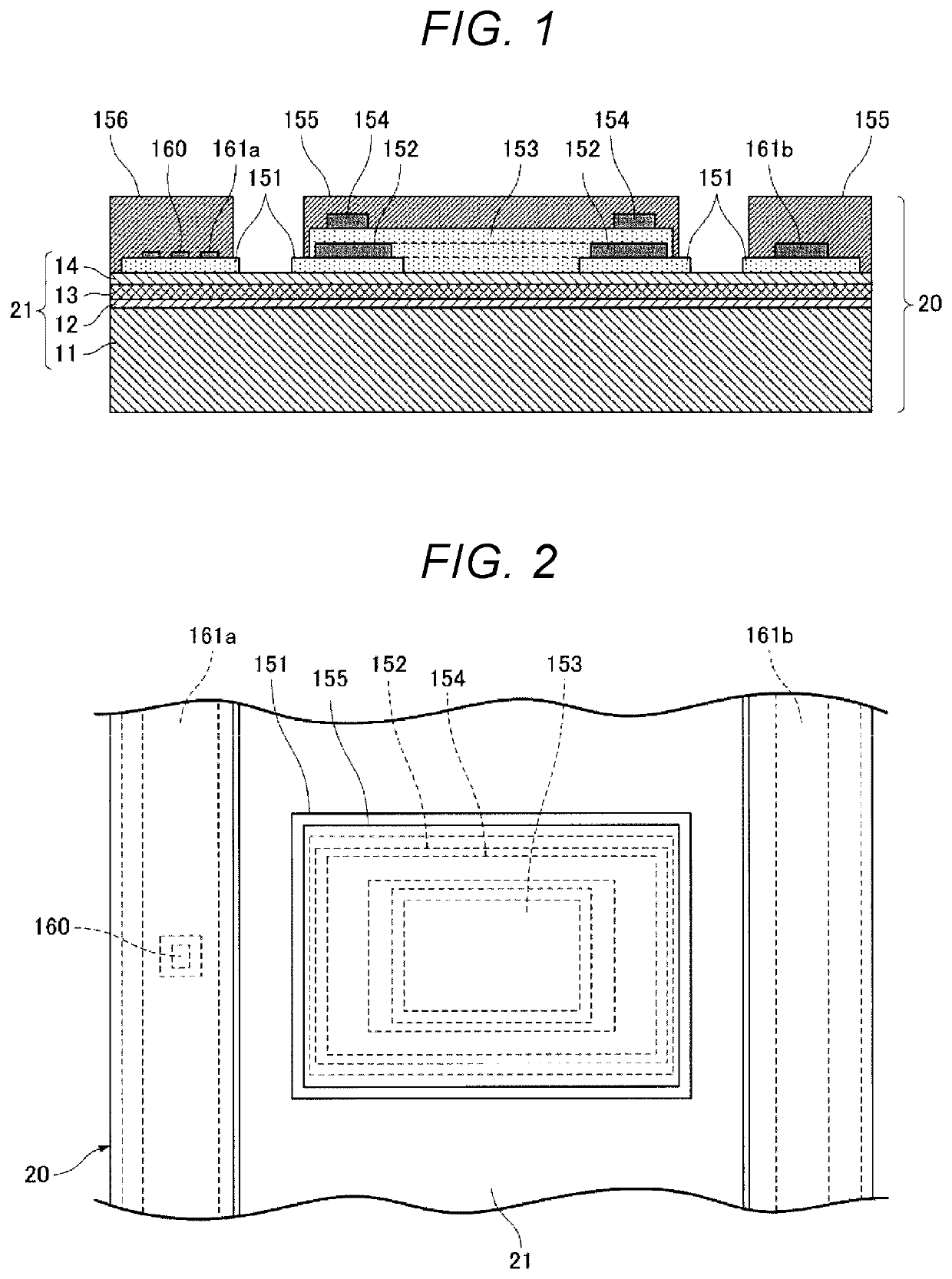

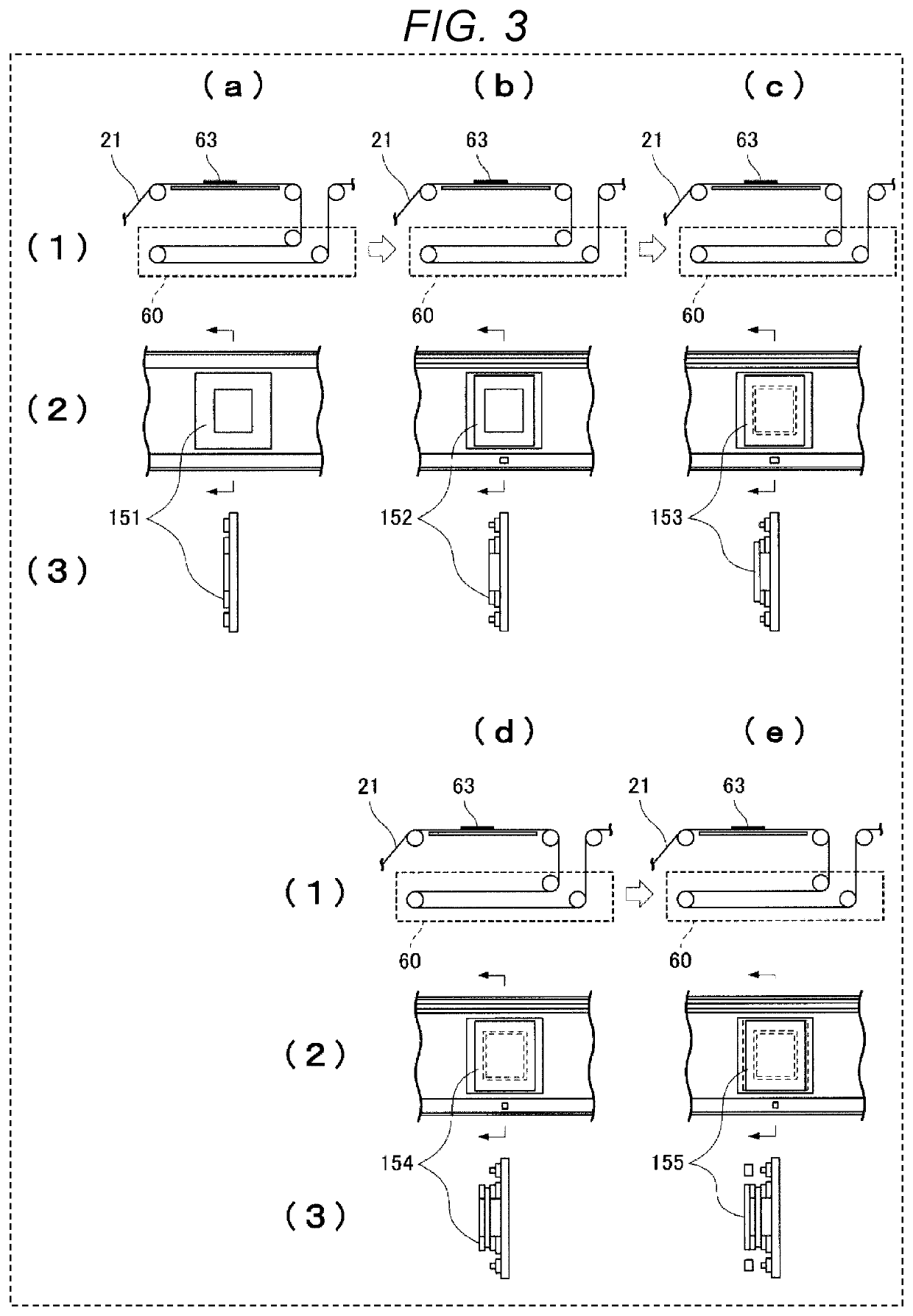

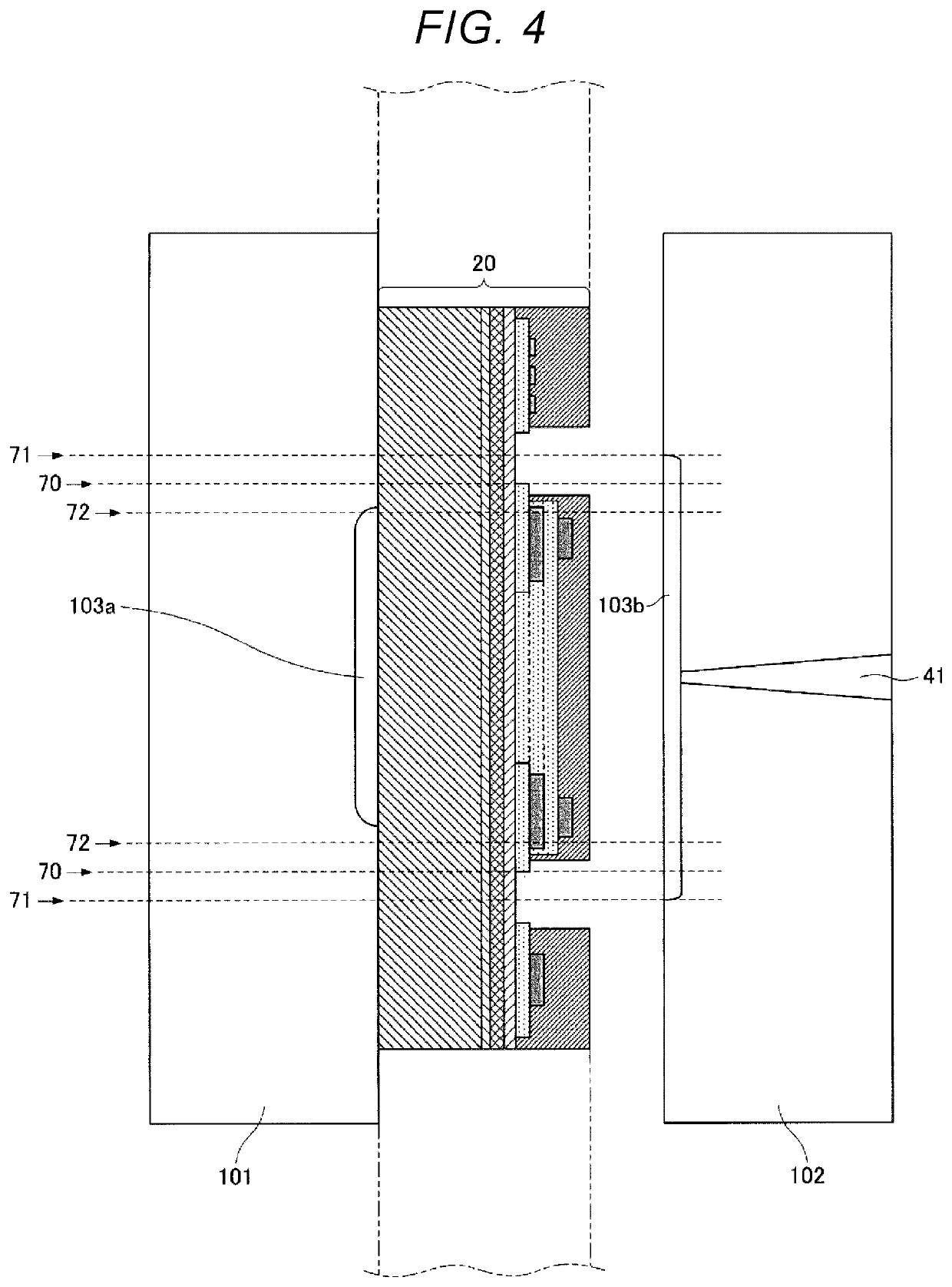

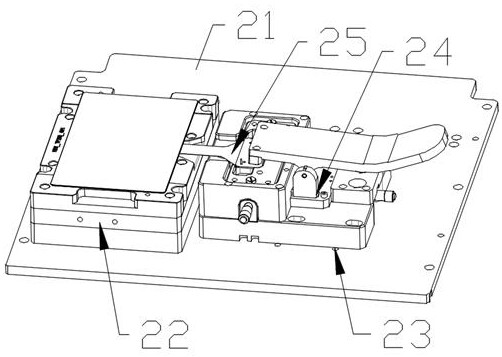

Finisher and image forming apparatus equipped therewith

ActiveUS7328893B2High precision sizeSimple configurationMechanical working/deformationFunction indicatorsEngineeringMechanical engineering

A finisher for finishing a booklet having a bundle of center-folded sheets, includes: a detector for detecting an end on a side of a folded portion of the booklet: a moving device for conveying the booklet by movement thereof; a controller for controlling the movement of the moving device; and a cutting device for cutting an edge on a side opposite to the end of the booklet, which has been conveyed by the moving device to a cutting position. The controller controls the movement of the moving device from a position where the detector has detected the end of the folded portion to the cutting position so that a size of a booklet after being cut is kept constant for each of sheet sizes.

Owner:KONICA MINOLTA BUSINESS TECH INC

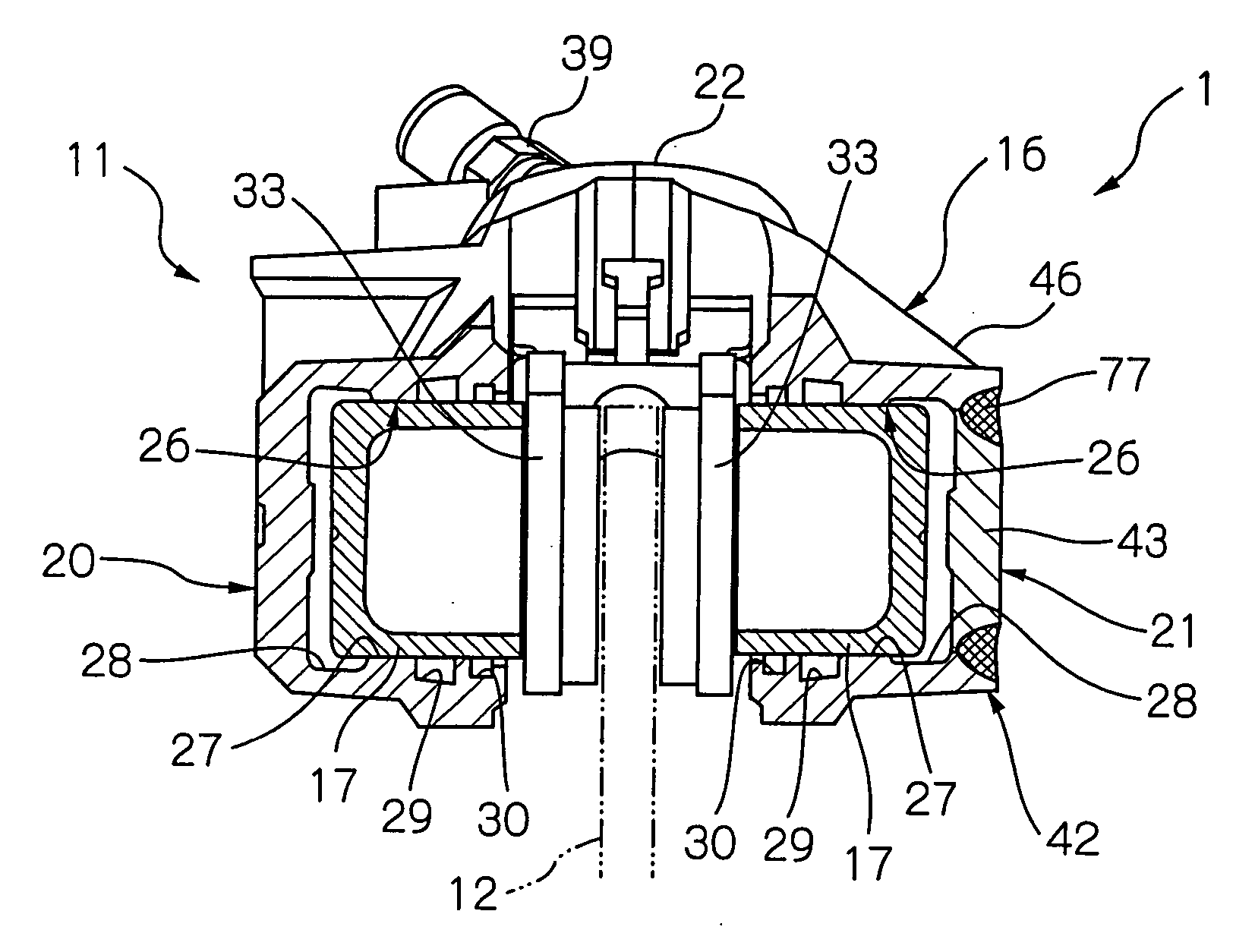

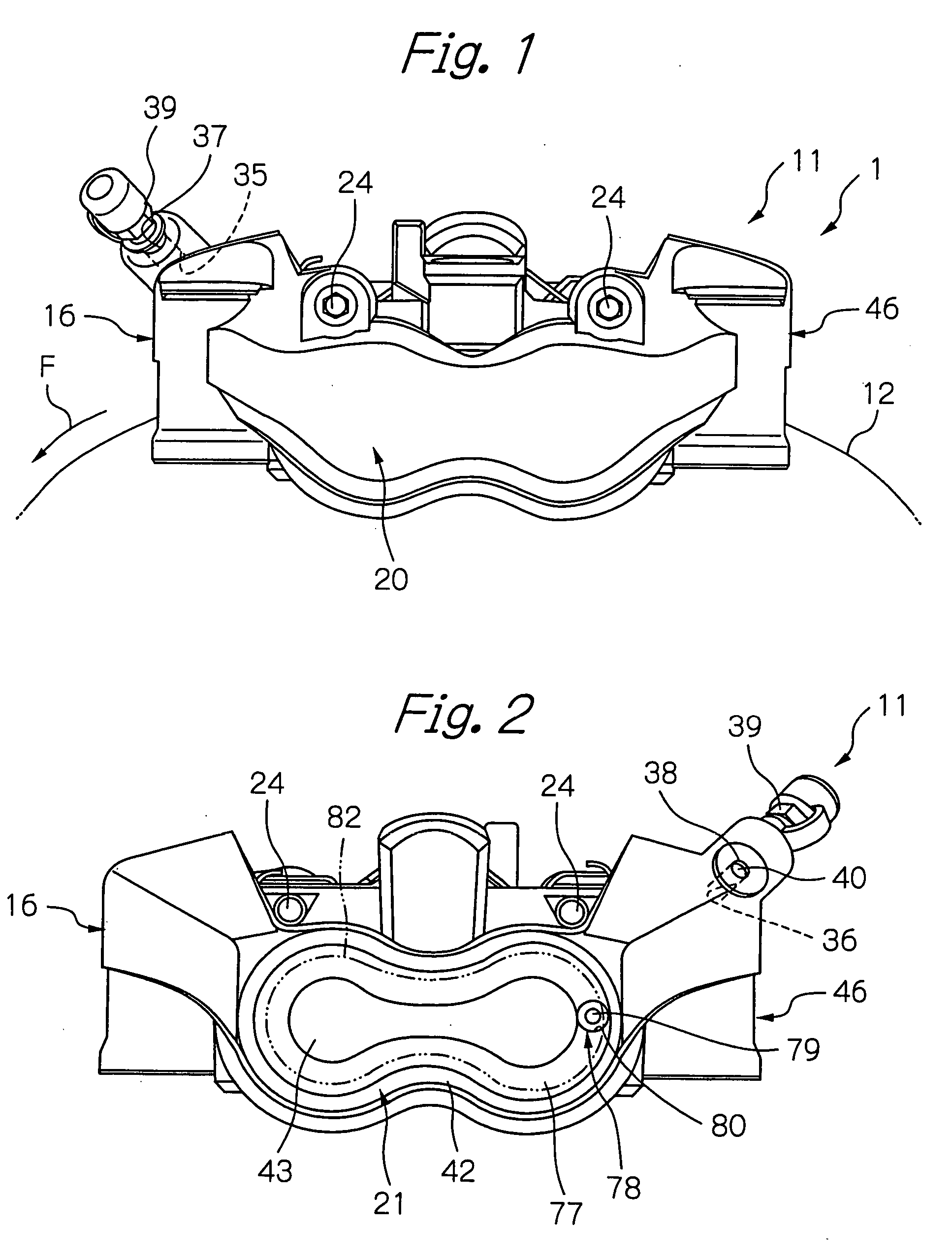

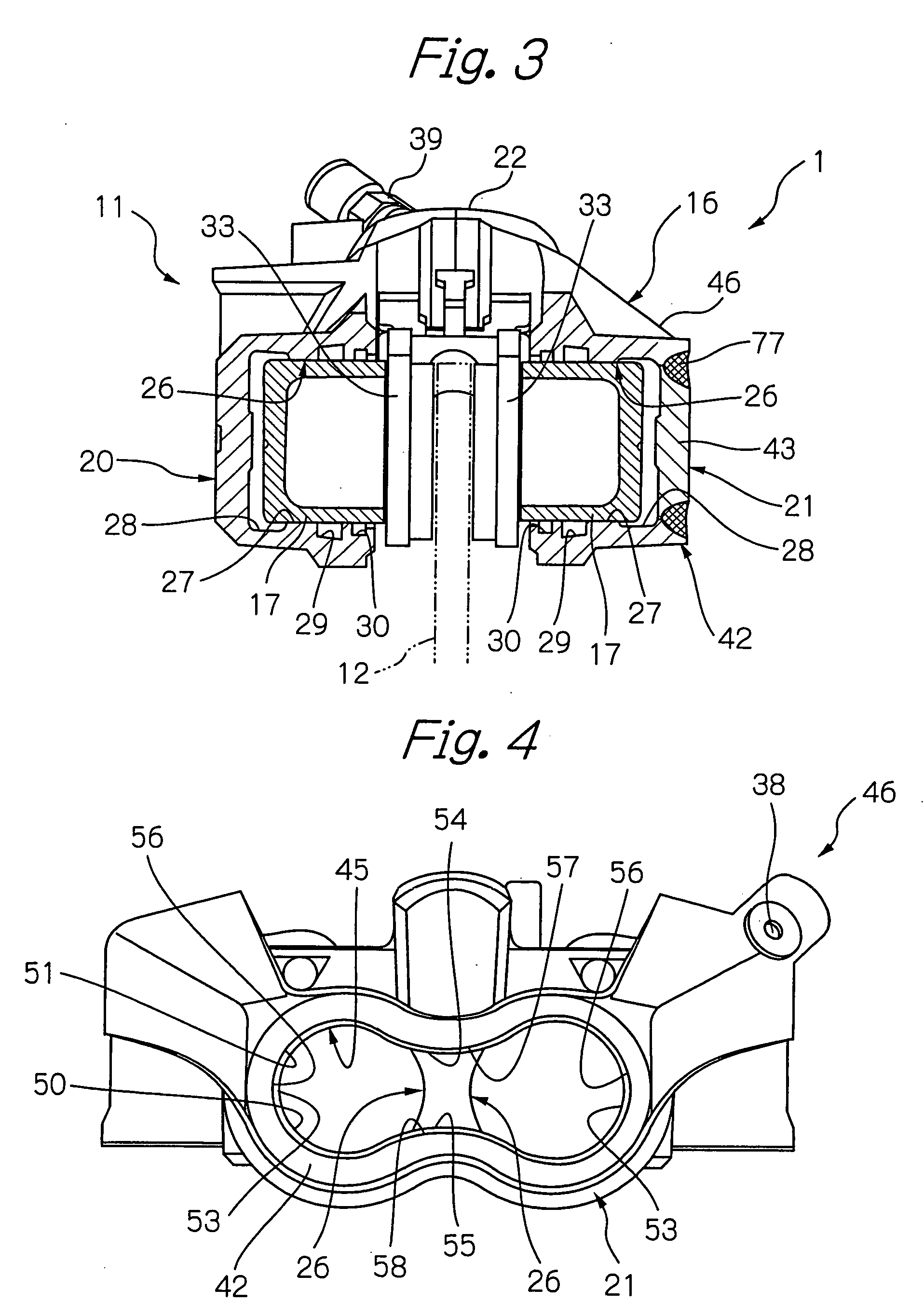

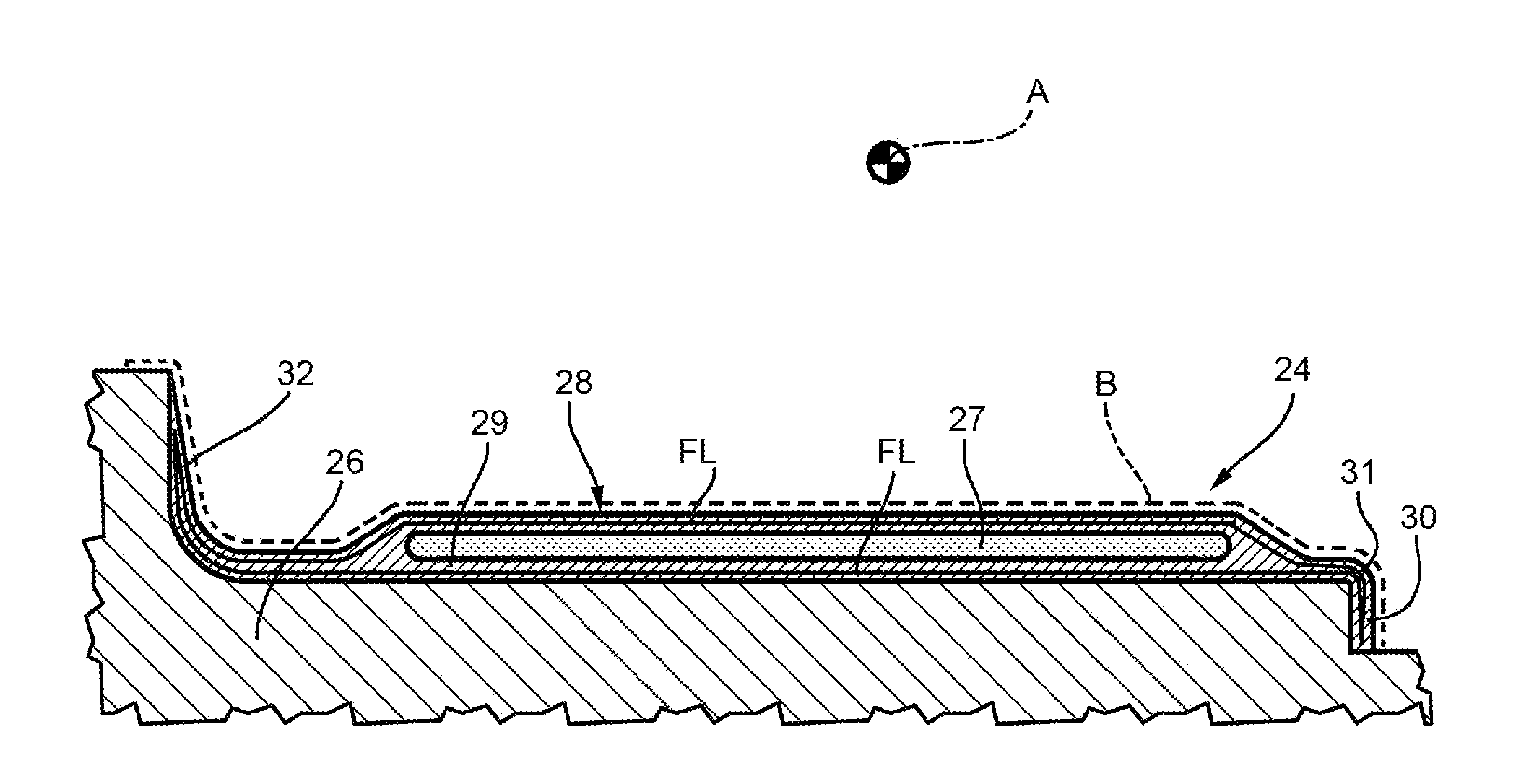

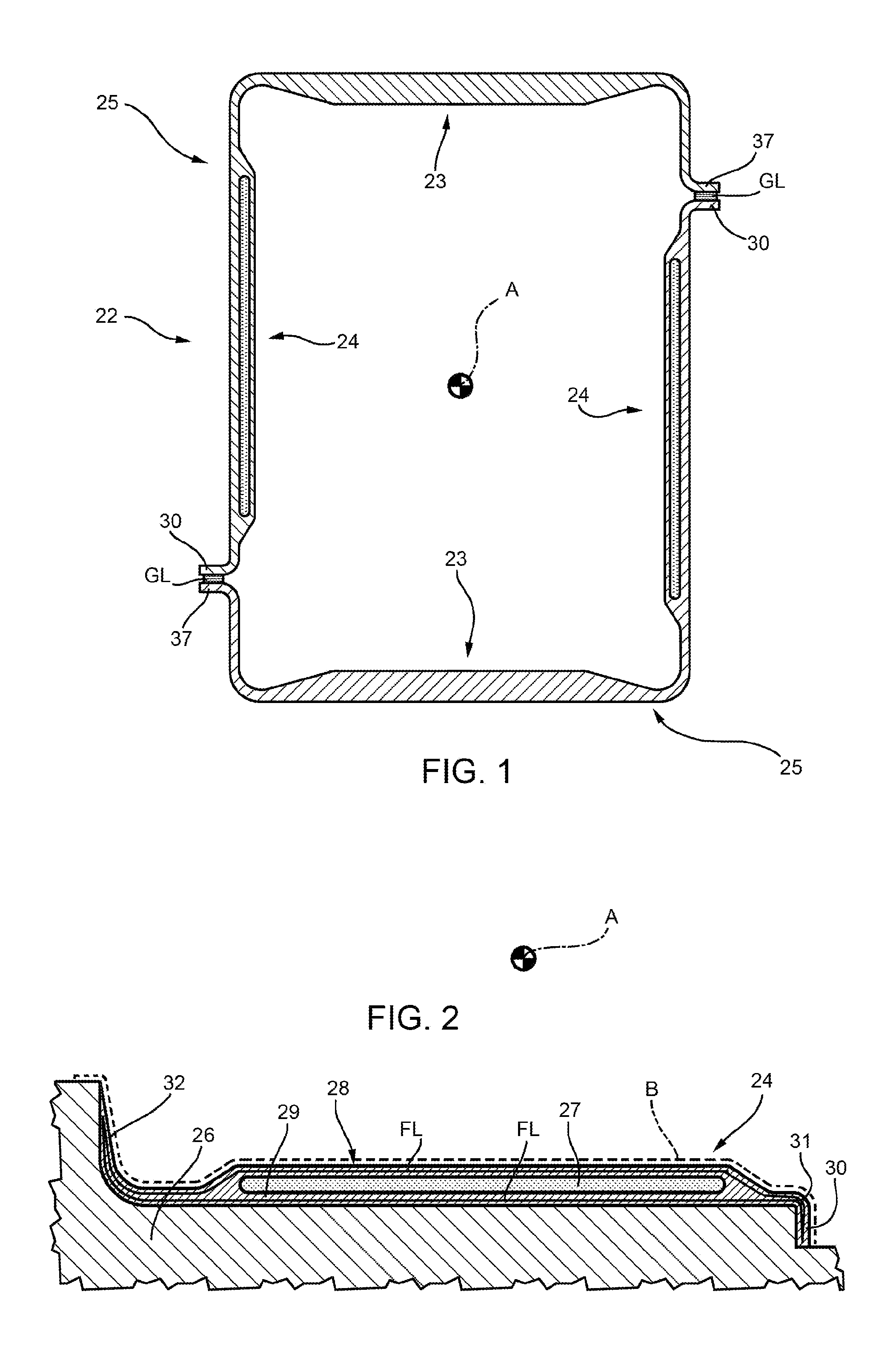

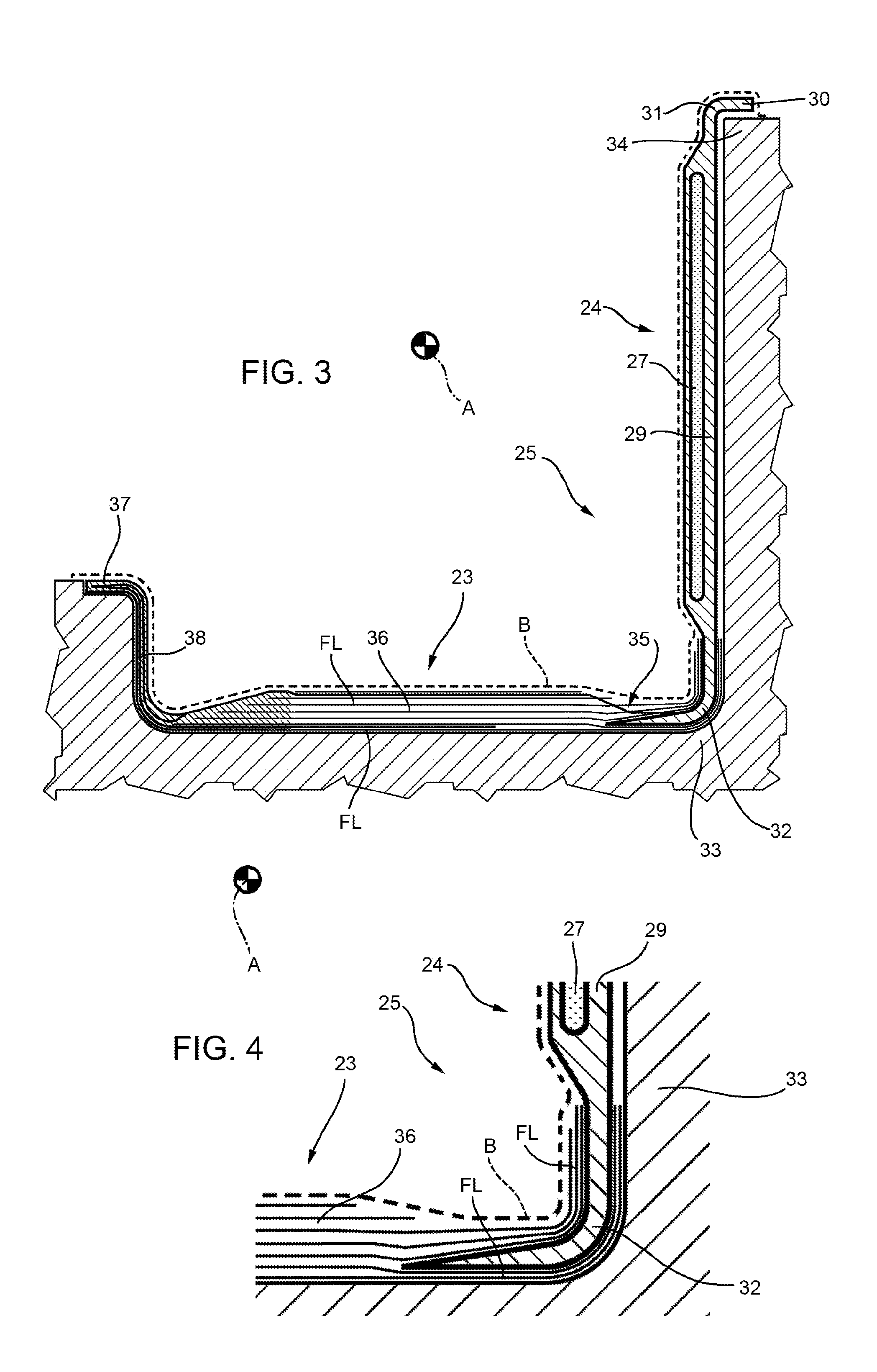

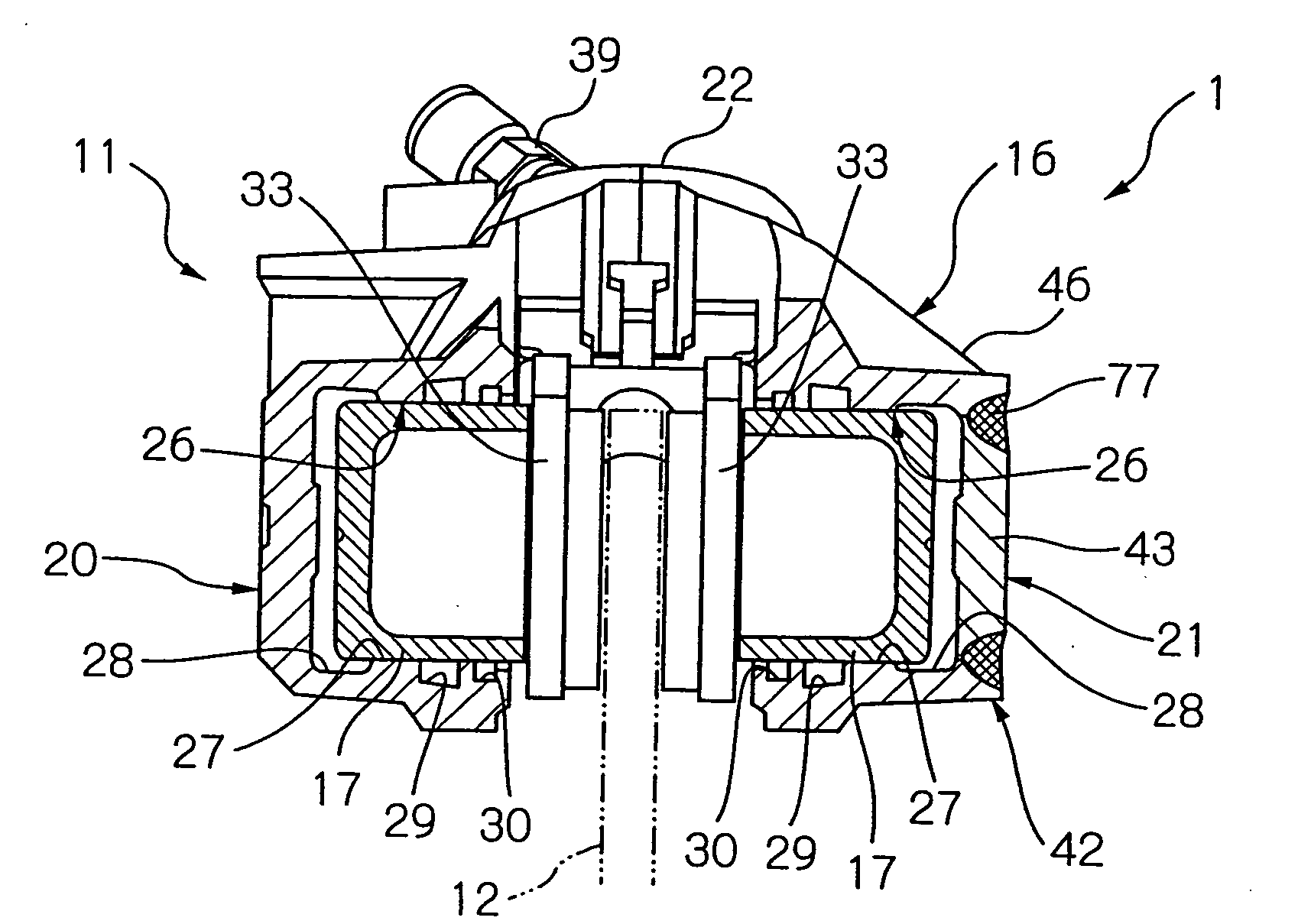

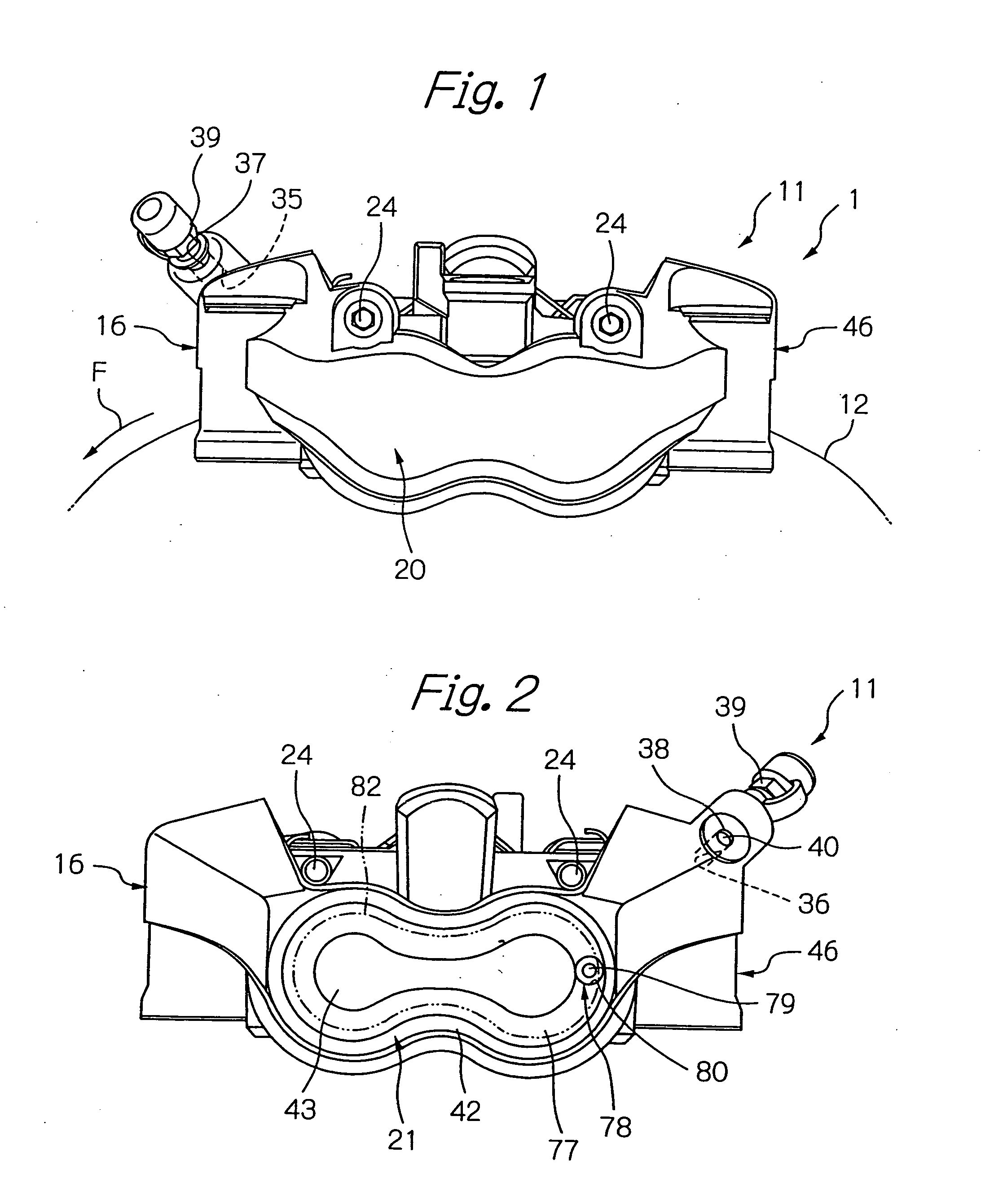

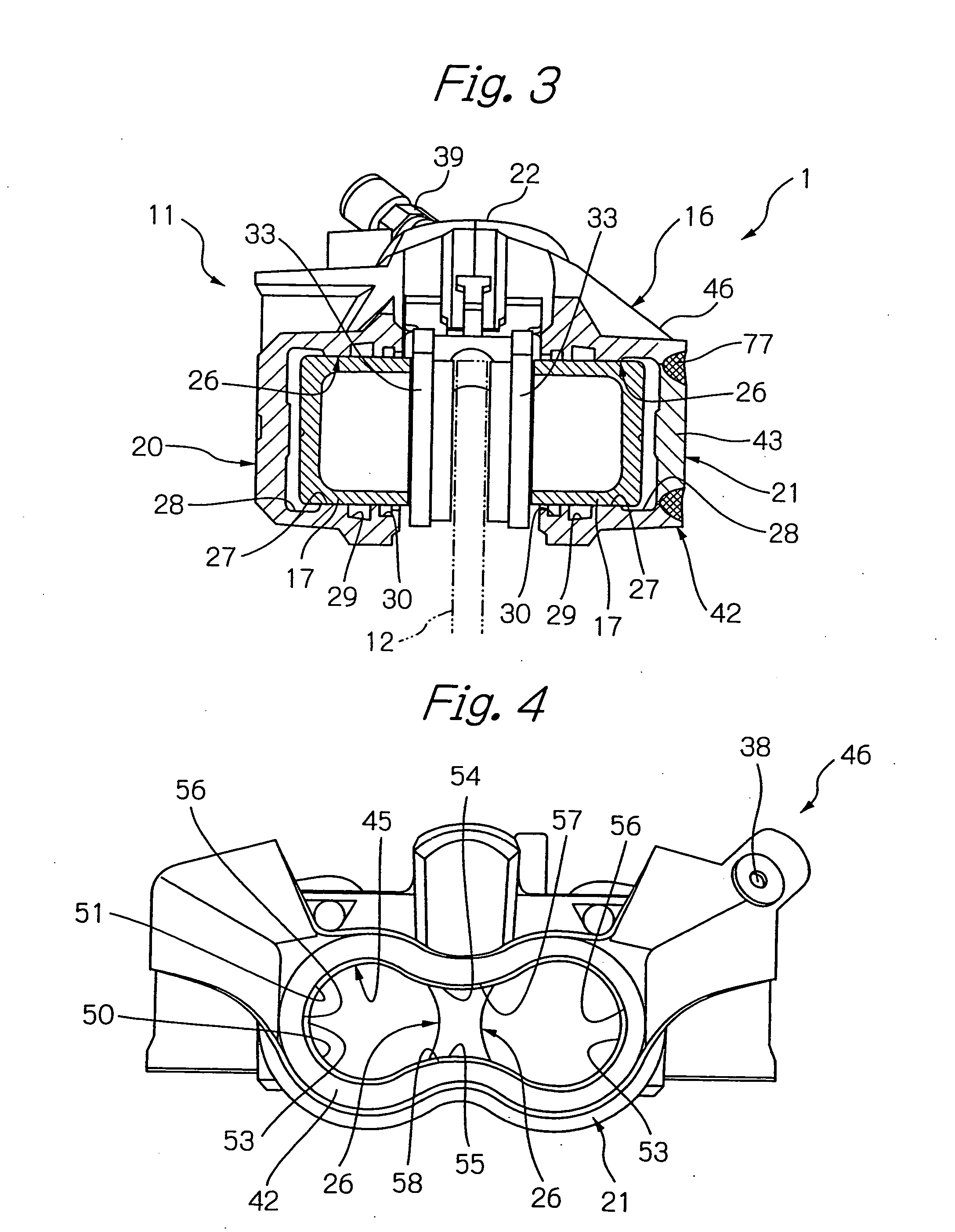

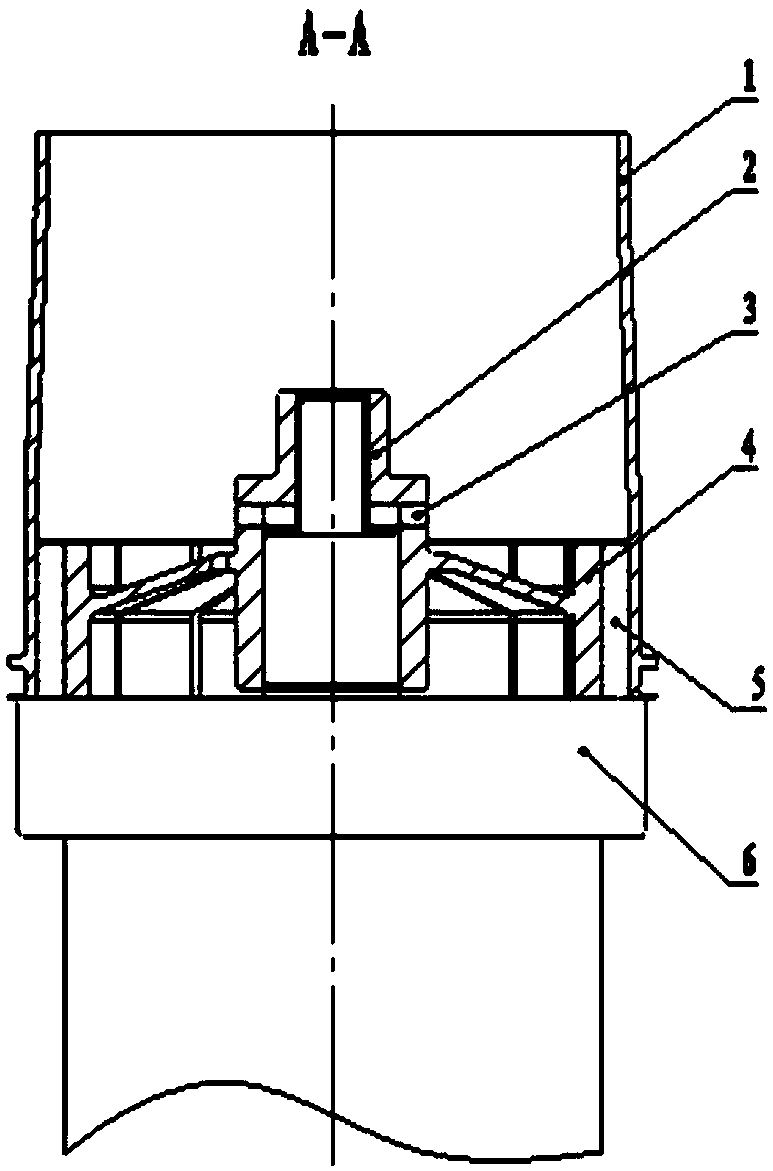

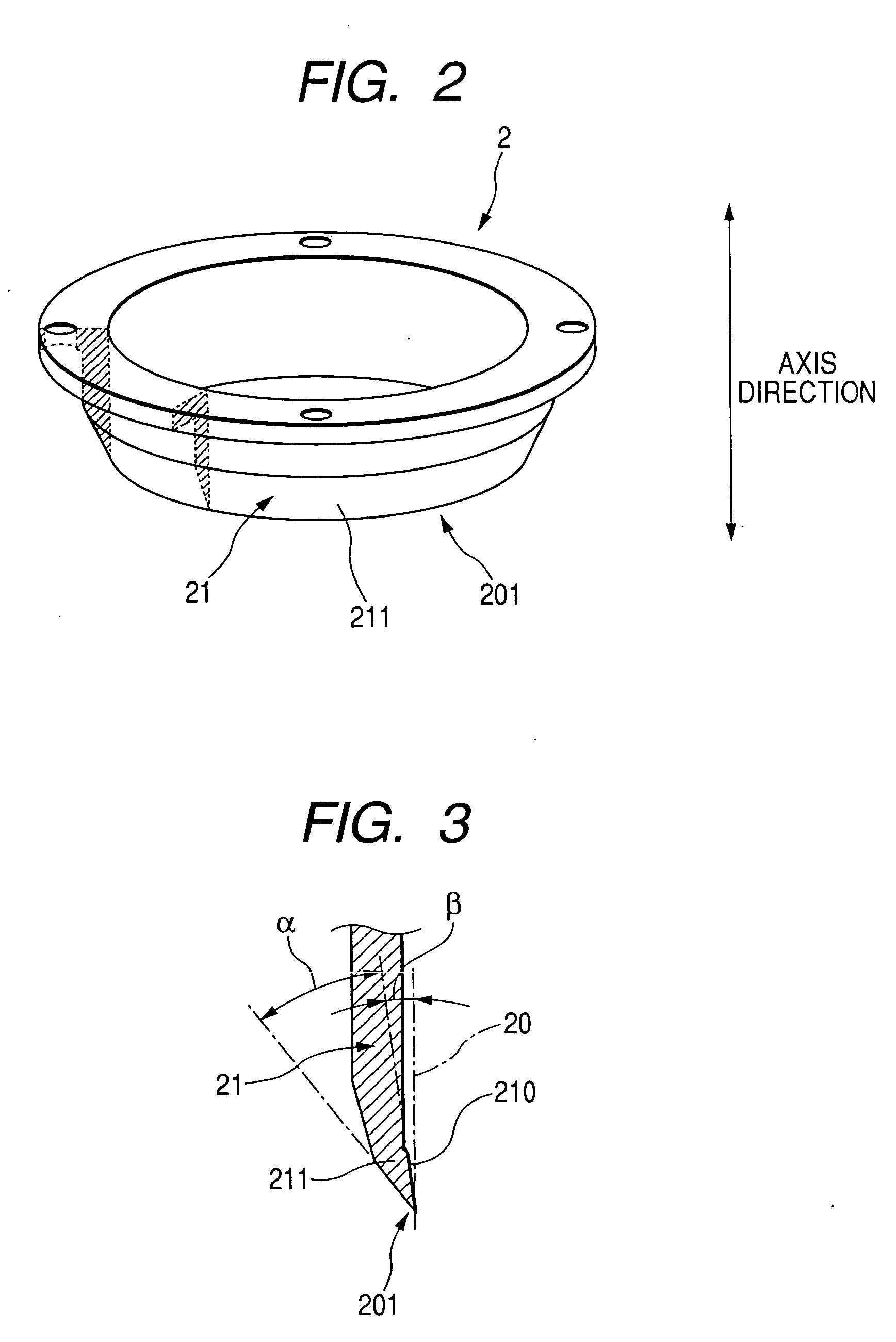

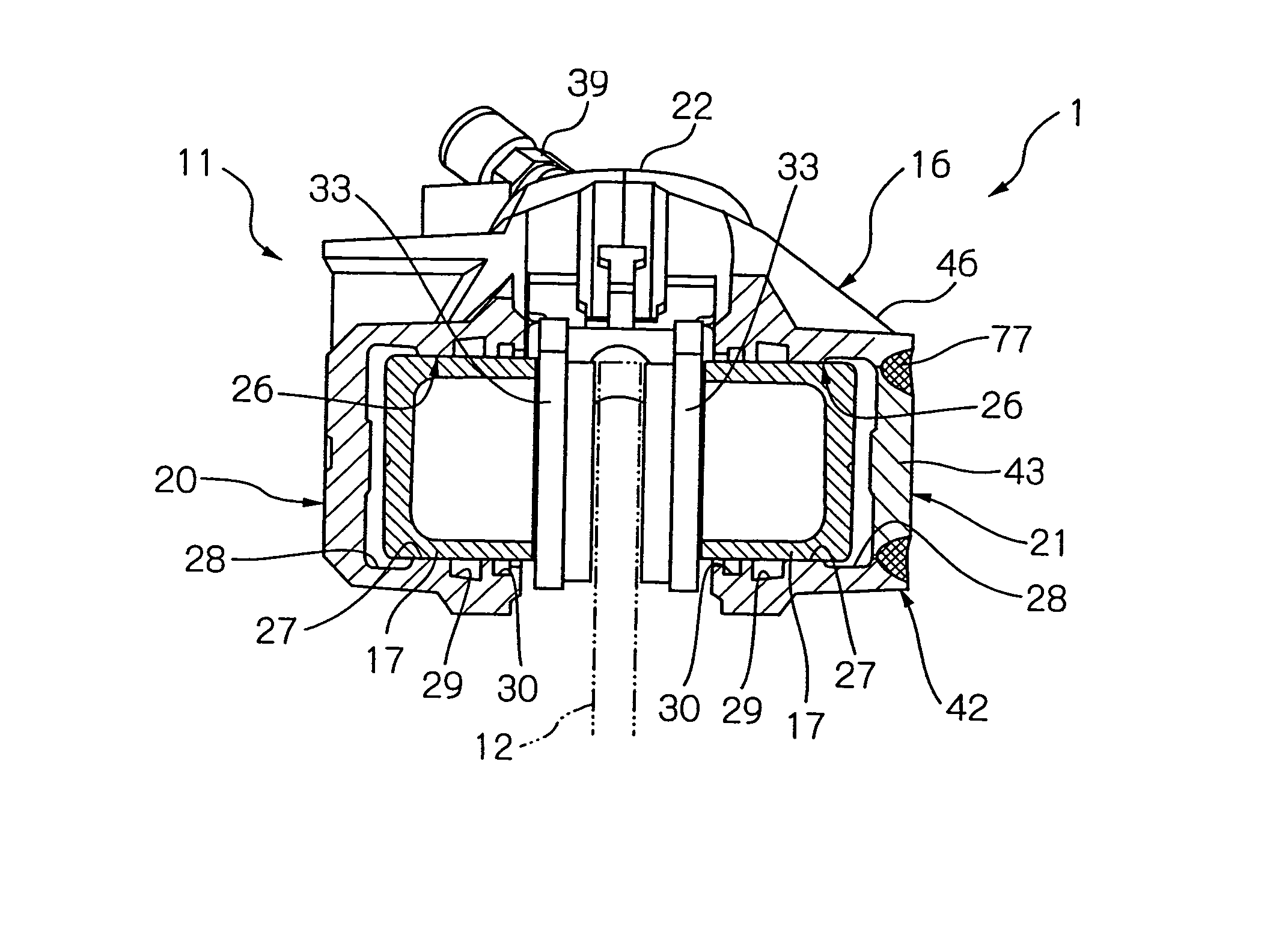

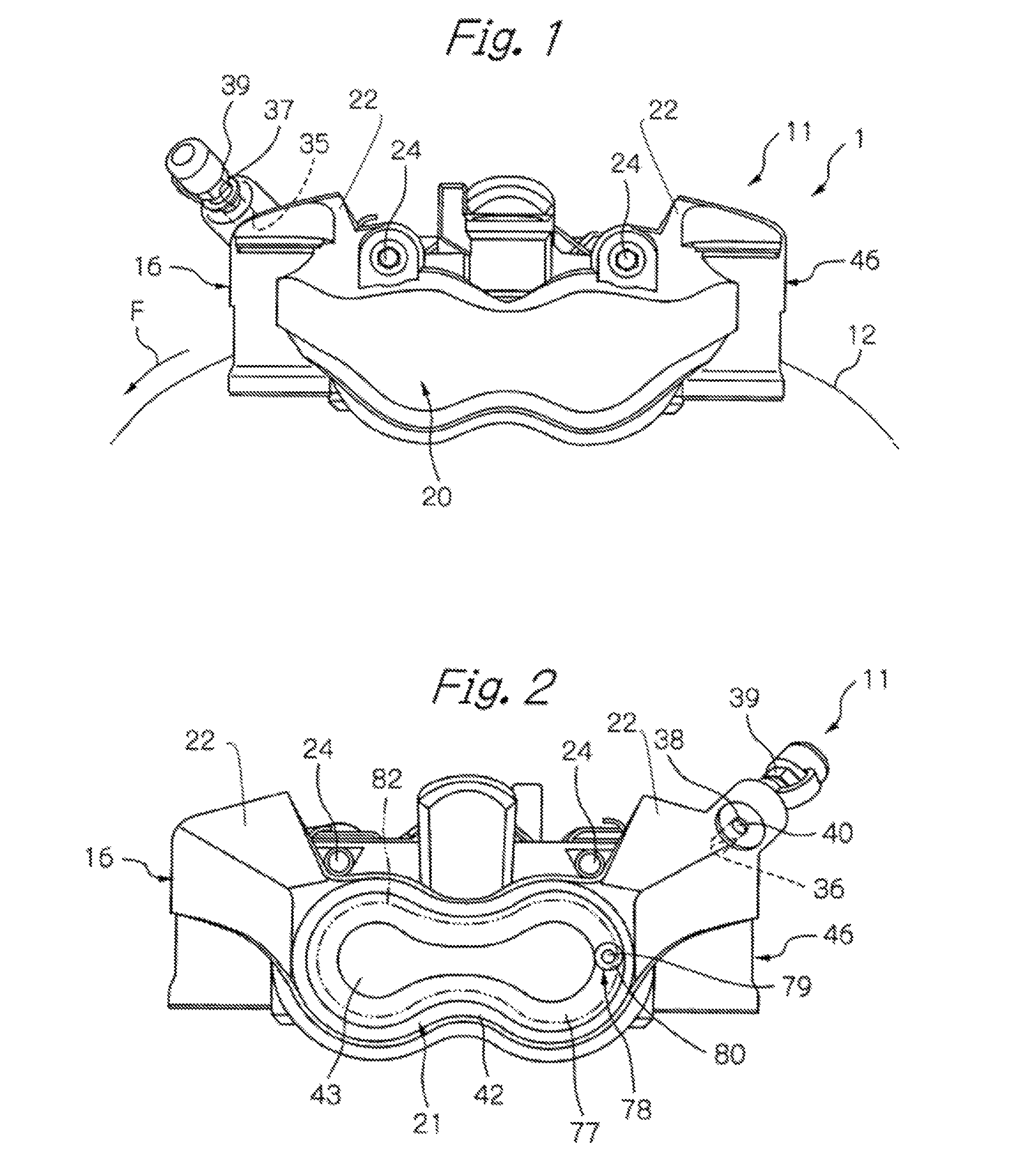

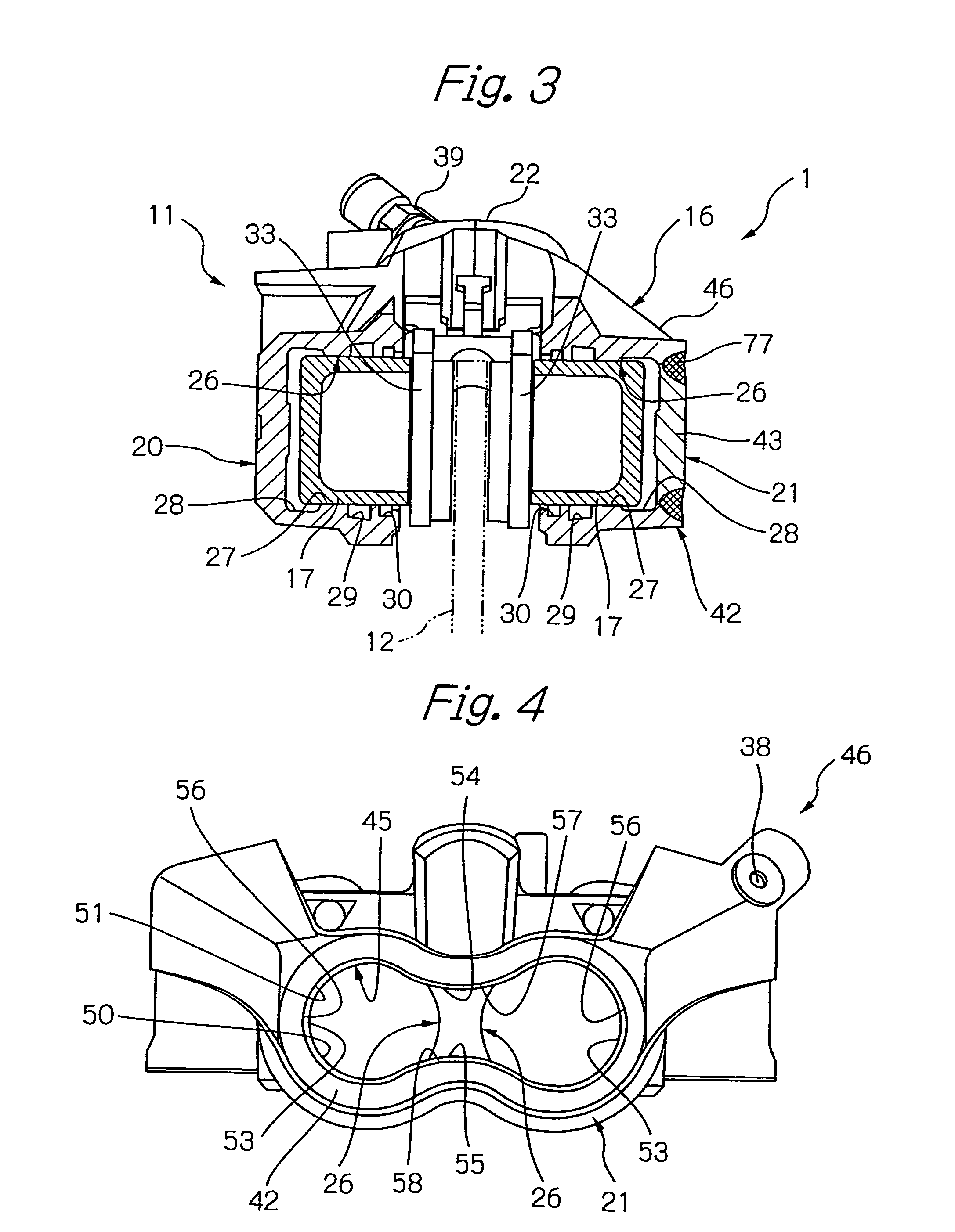

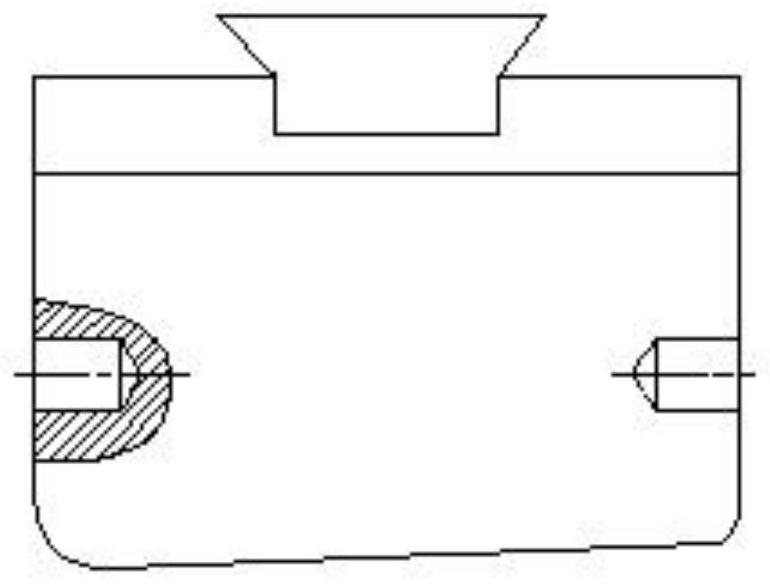

Cylinder apparatus and disk brake

ActiveUS20060175156A1No reduction in strengthHigh strengthAxially engaging brakesBraking action transmissionEngineeringMechanical engineering

The present invention provides a cylinder apparatus wherein although an opening of a cylinder body is closed by a covering member, processing and parts' costs are reduced, fluid leakage is prevented, and the apparatus can be reduced in size. A cylinder apparatus in which a piston 17 is caused to slidingly move in a bore 26 of a cylinder 21, the cylinder 21 comprising: a covering member 43 provided in a bottom portion 42 of the cylinder 21; and a cylinder body 46 having an opening that is closed by the covering member 43; the covering member 43 being friction stir welded to the cylinder body 46.

Owner:HITACHI ASTEMO LTD

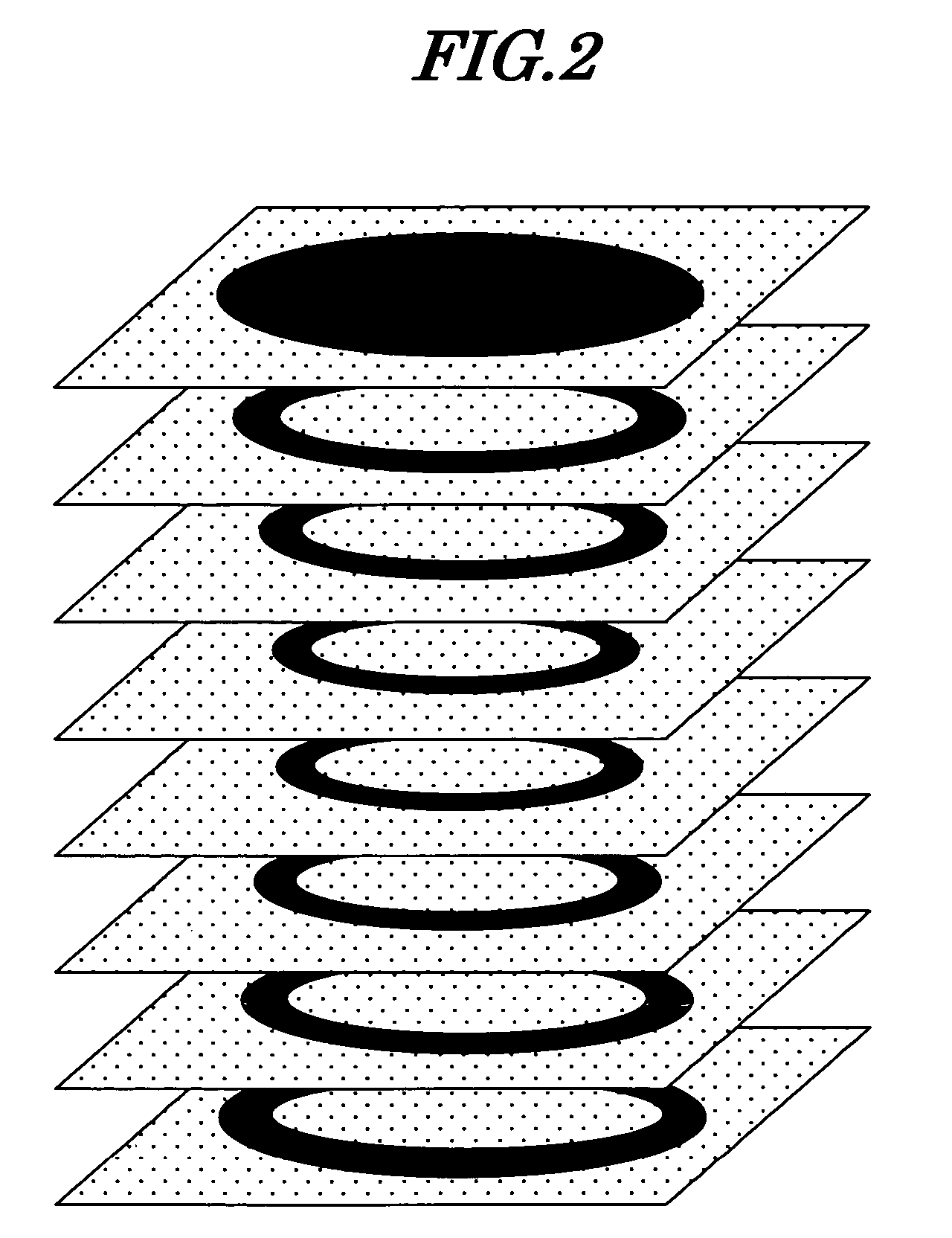

Finisher and image forming apparatus equipped therewith

ActiveUS20050230895A1Easy to controlQuality improvementMechanical working/deformationFunction indicatorsMechanical engineeringEngineering

A finisher for finishing a booklet having a bundle of center-folded sheets, includes: a detector for detecting an end on a side of a folded portion of the booklet: a moving device for conveying the booklet by movement thereof; a controller for controlling the movement of the moving device; and a cutting device for cutting an edge on a side opposite to the end of the booklet, which has been conveyed by the moving device to a cutting position. The controller controls the movement of the moving device from a position where the detector has detected the end of the folded portion to the cutting position so that a size of a booklet after being cut is kept constant for each of sheet sizes.

Owner:KONICA MINOLTA BUSINESS TECH INC

Wind turbine blade tubular spar fabricating method

InactiveUS20130334735A1Drawback can be obviatedHighly precise dimensionFinal product manufactureLaminationTurbine bladeEngineering

A method of fabricating a wind turbine blade tubular spar, wherein the tubular spar extends along a designated axis, is made of reinforced polymer material having fibers arranged in at least two directions, and a polymer matrix incorporating the fibers, and has two caps and two webs; the method including the steps of: molding and cross-linking at least part of a cap or web in composite material; molding and cross-linking an L-shaped structure, which has two opposite parallel flanges, and at least partly incorporates the previously molded, cross-linked cap or web of composite material; repeating the above steps to mold and cross-link a further L-shaped structure; and joining the two cross-linked, L-shaped structures, with the flanges positioned facing in pairs.

Owner:WINDFIN

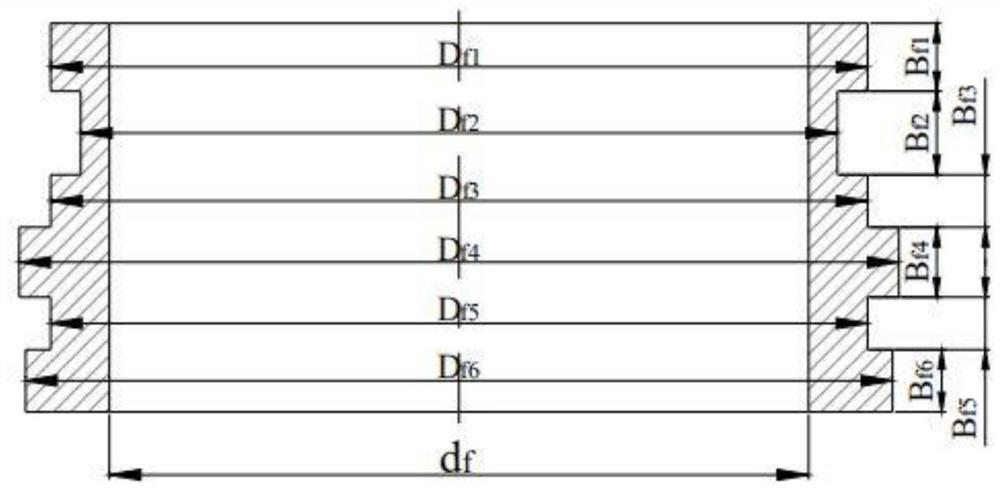

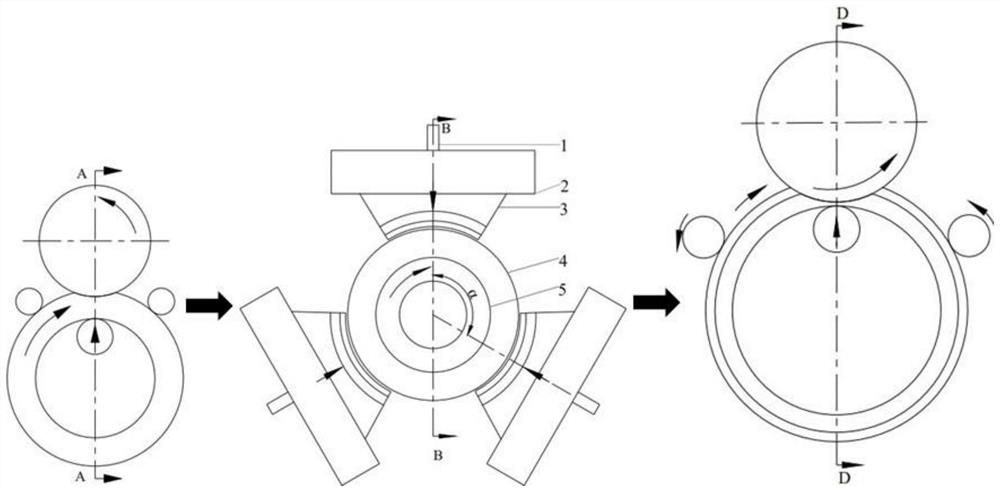

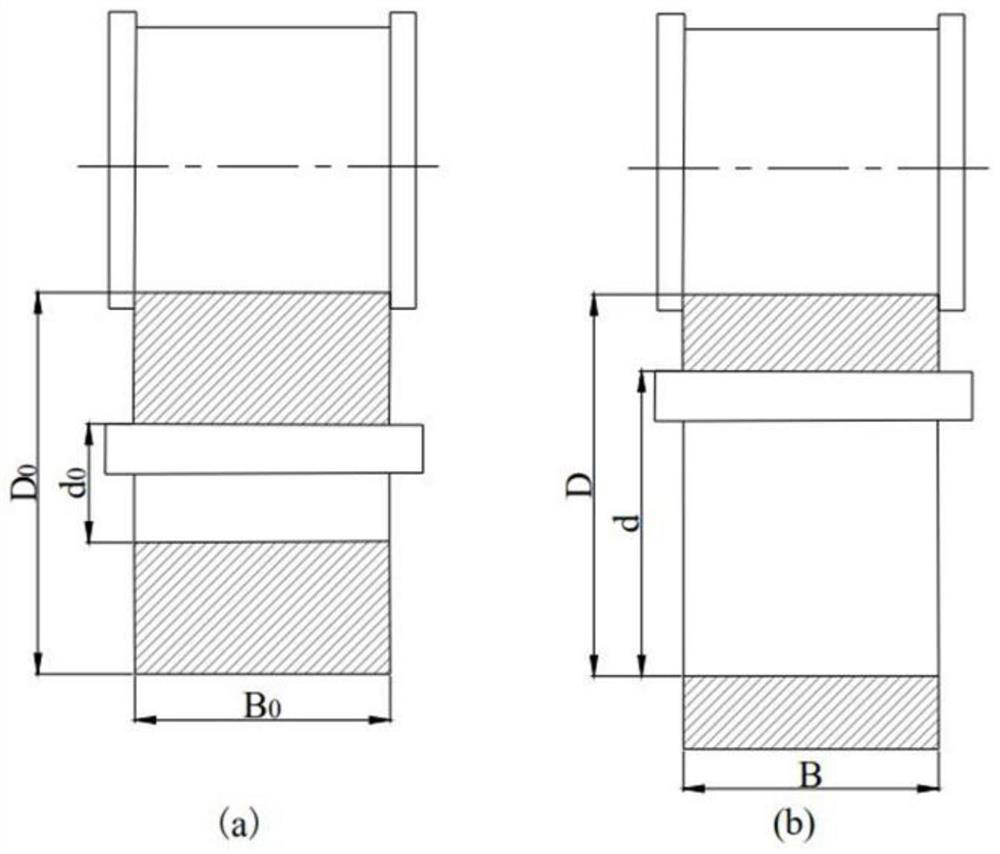

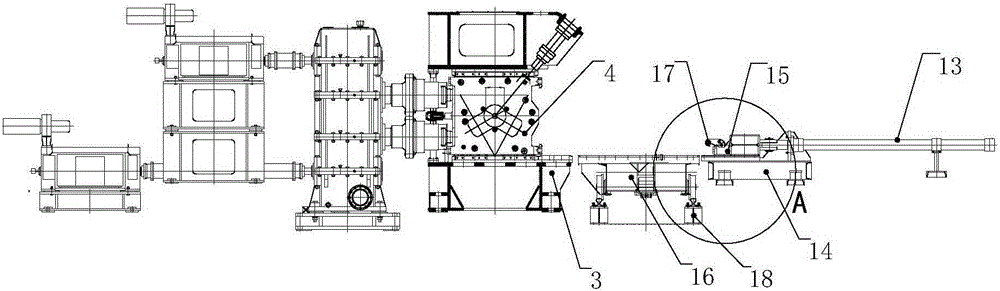

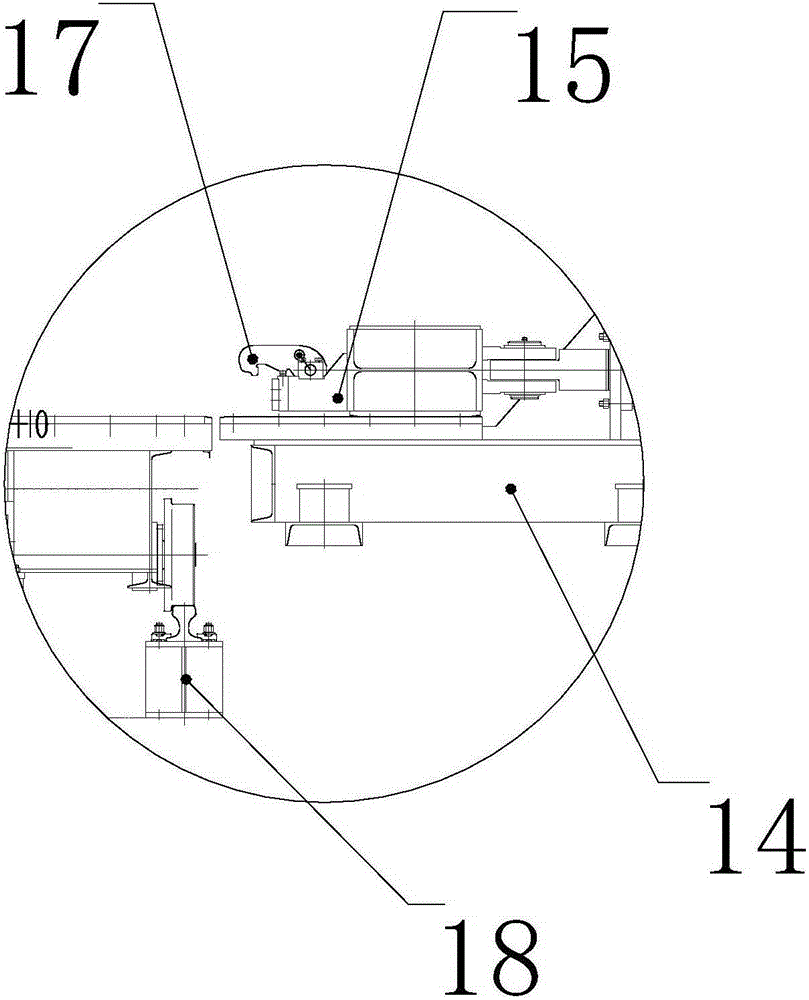

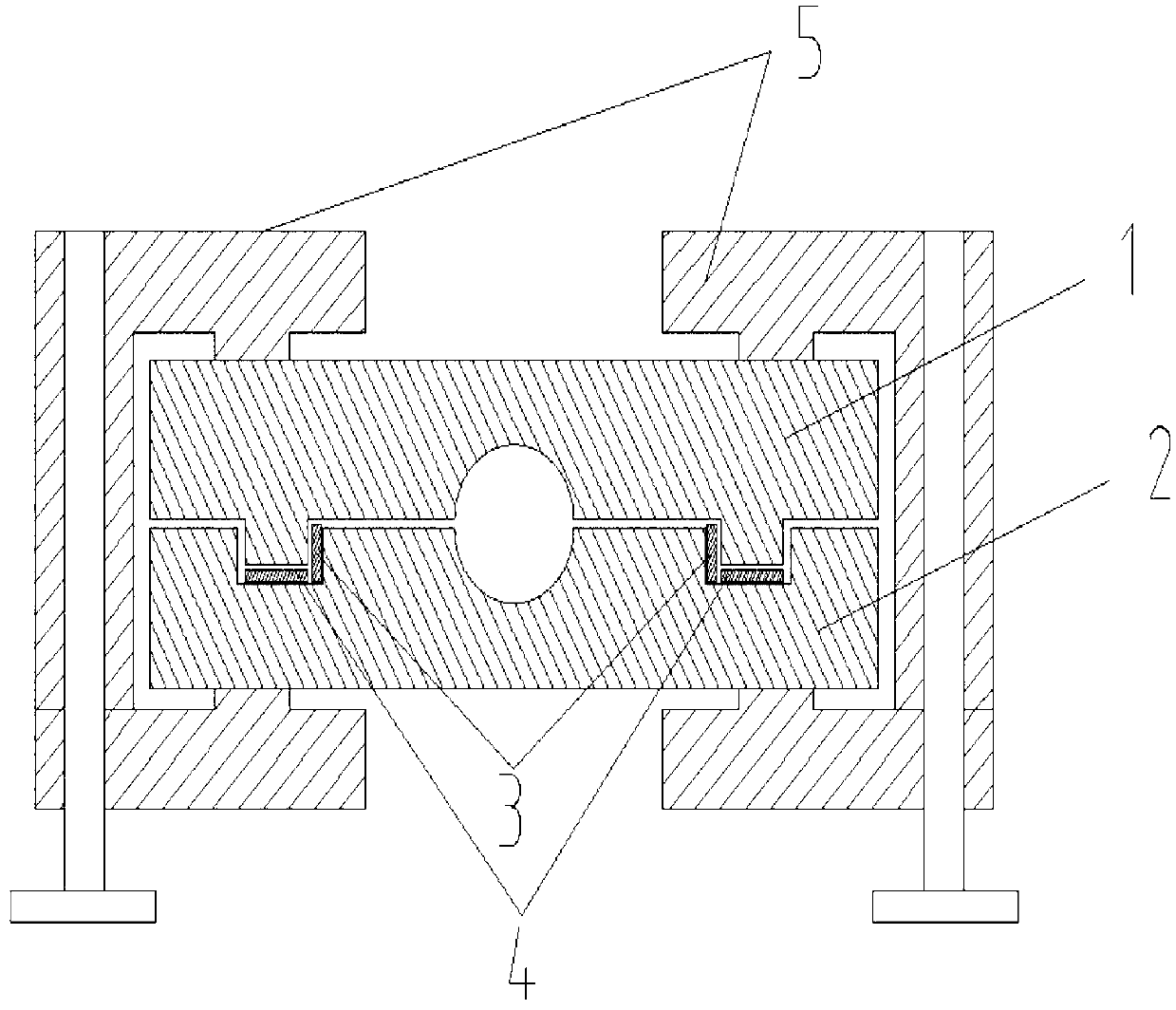

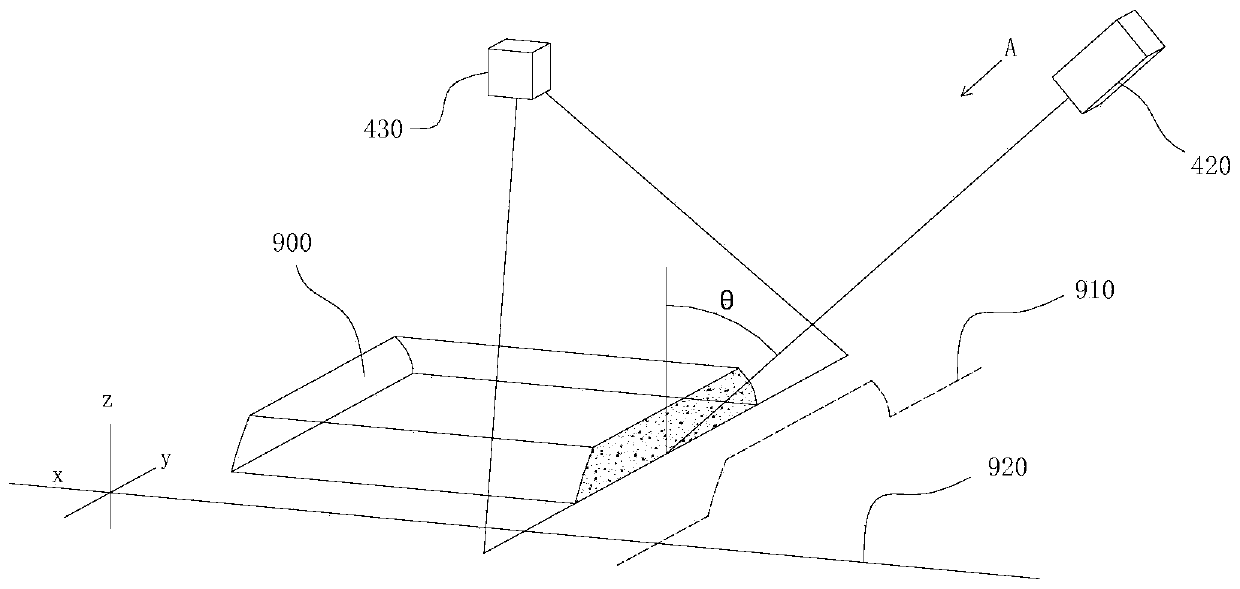

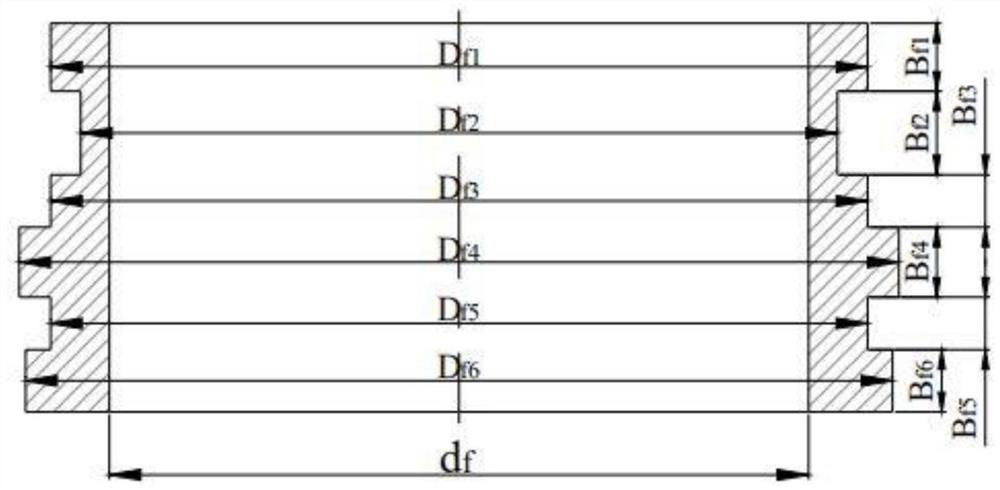

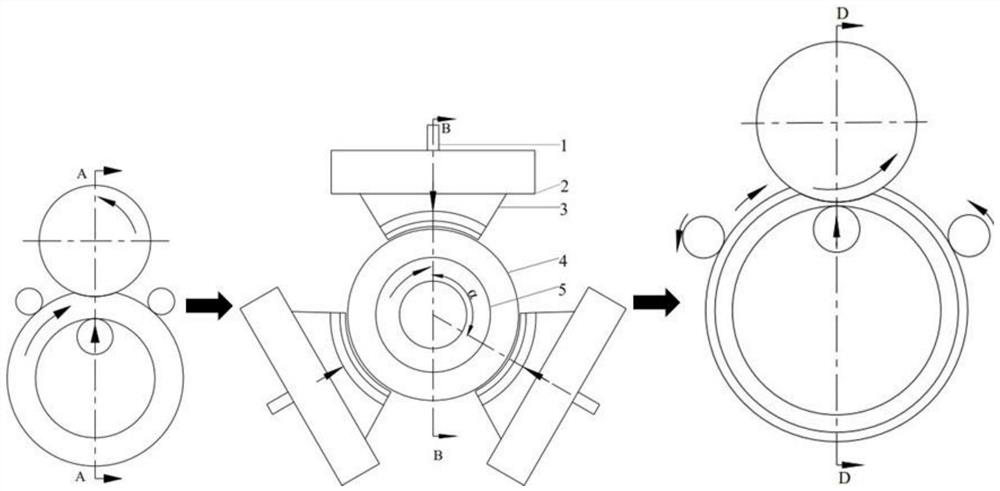

Rolling-extruding composite near-net forming method for large ring piece having outer contour with abrupt-change section

ActiveCN113084054AInhibit growthPrevent axial movementGeometric CADSpecial data processing applicationsPunchingEnergy consumption

The invention discloses a rolling-extruding composite near-net forming method for a large ring piece having an outer contour with an abrupt-change section. The rolling-extruding composite near-net forming method for the large ring piece having the outer contour with the abrupt-change section comprises the following steps: S1, a blank obtained after upsetting and punching is subjected to pre-rolling forming, and a large-diameter ring blank with the rectangular section and uniform wall thickness is obtained; S2, the ring blank subjected to the pre-rolling forming is placed on an extrusion die, the extrusion die comprises a core die with limiting flanges at the two ends and a plurality of petal dies evenly distributed around the axis, the petal dies are provided with multiple stages of extrusion blocks in the axial direction, each stage of extrusion block is controlled by a respective high-pressure push rod to work, multi-direction continuous local incremental radial extrusion is adopted, and the abrupt-change contour of the outer surface of the ring blank is formed step by step in the axial direction, and a special-shaped ring blank is obtained; and S3, the special-shaped ring blank is subjected to radial closed type near-net rolling forming, and the target ring piece is obtained. The method is smaller in forming force, lower in energy consumption, capable of restraining the outer diameter of the ring piece from being increased, high in material utilization rate and capable of greatly improving the comprehensive performance of products.

Owner:WUHAN UNIV OF TECH

Cylinder apparatus and disk brake

ActiveUS20080289916A1High precision sizeReduce processing costsValve arrangementsAxially engaging brakesEngineeringMechanical engineering

A method of manufacturing a cylinder apparatus wherein although an opening of a cylinder body is closed by a covering member, processing and parts costs are reduced, fluid leakage is prevented, and the apparatus can be reduced in size. The cylinder apparatus includes a piston (17) which is caused to slidingly move in a bore (26) of a cylinder (21). The cylinder 21 includes a covering member (43) provided in a bottom portion (42) of the cylinder (21), and a cylinder body (46) having an opening that is closed by the covering member (43). The covering member (43) is friction stir welded to the cylinder body (46).

Owner:HITACHI ASTEMO LTD

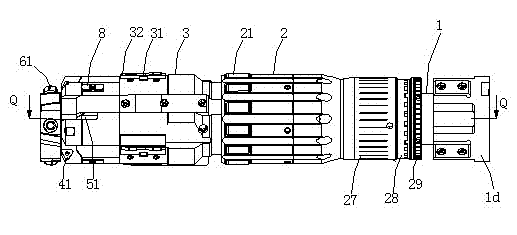

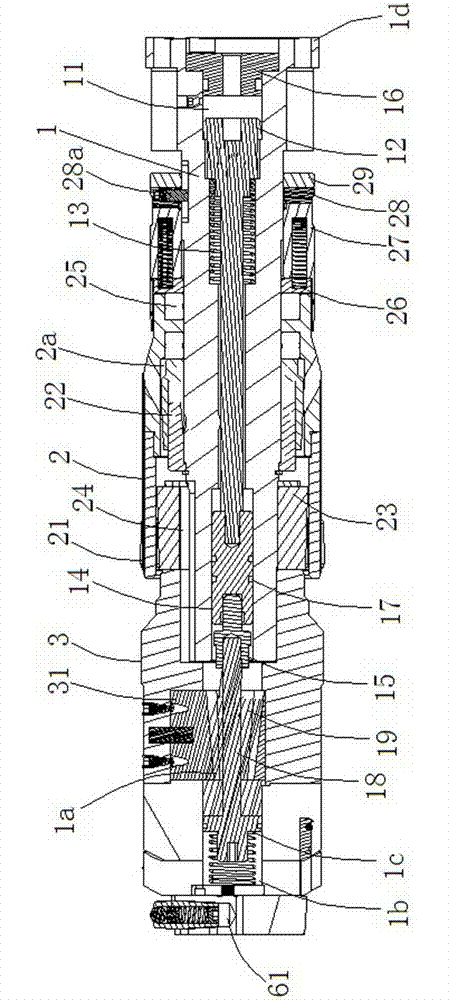

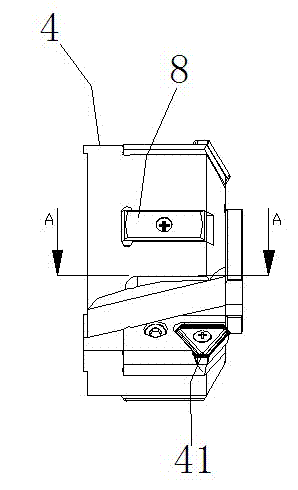

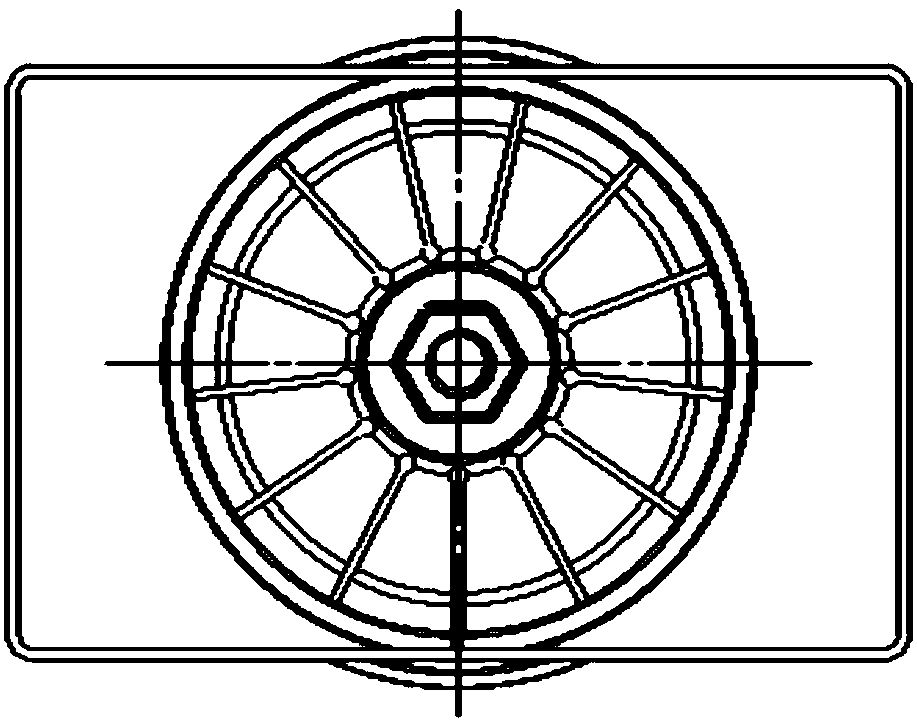

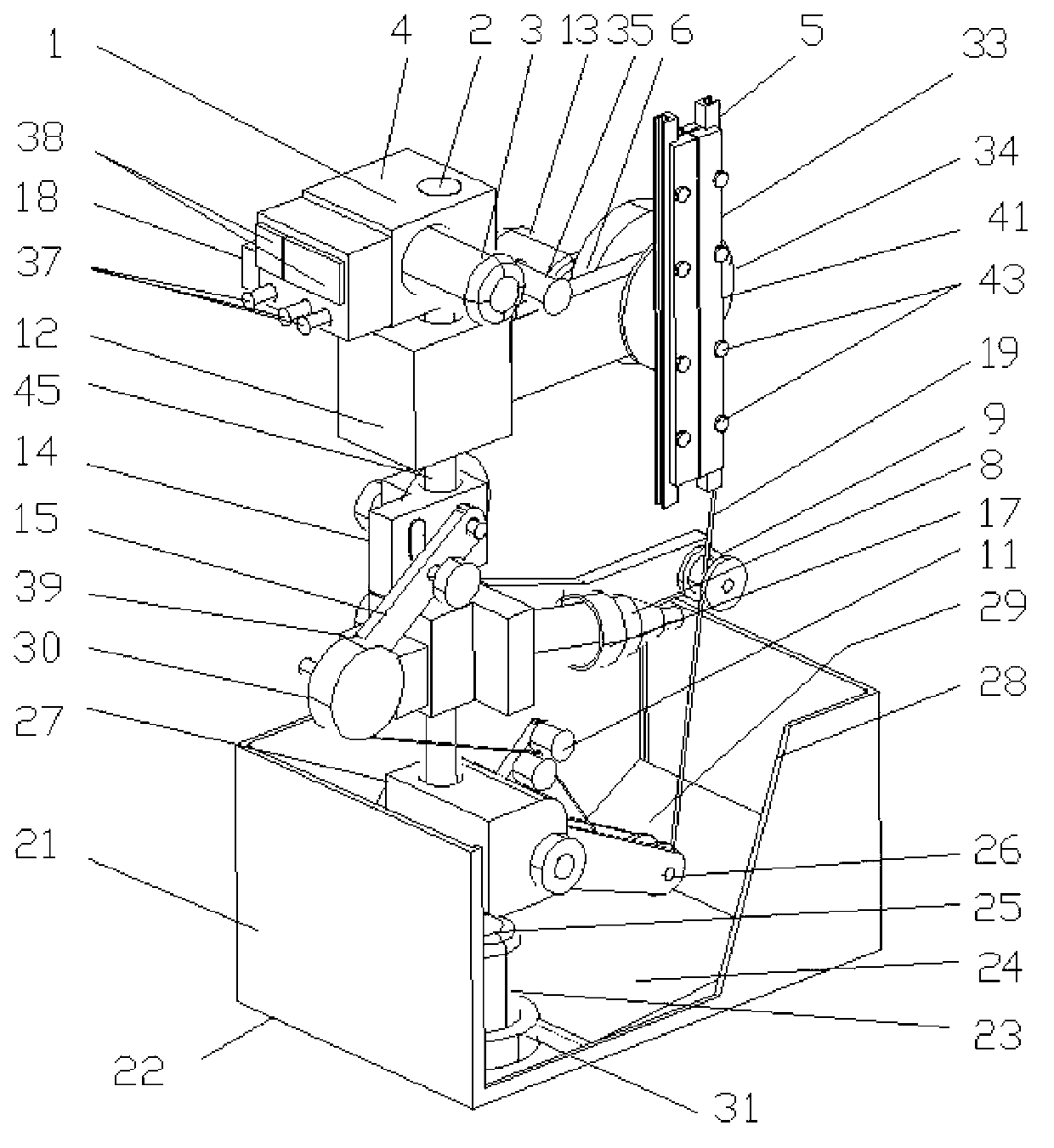

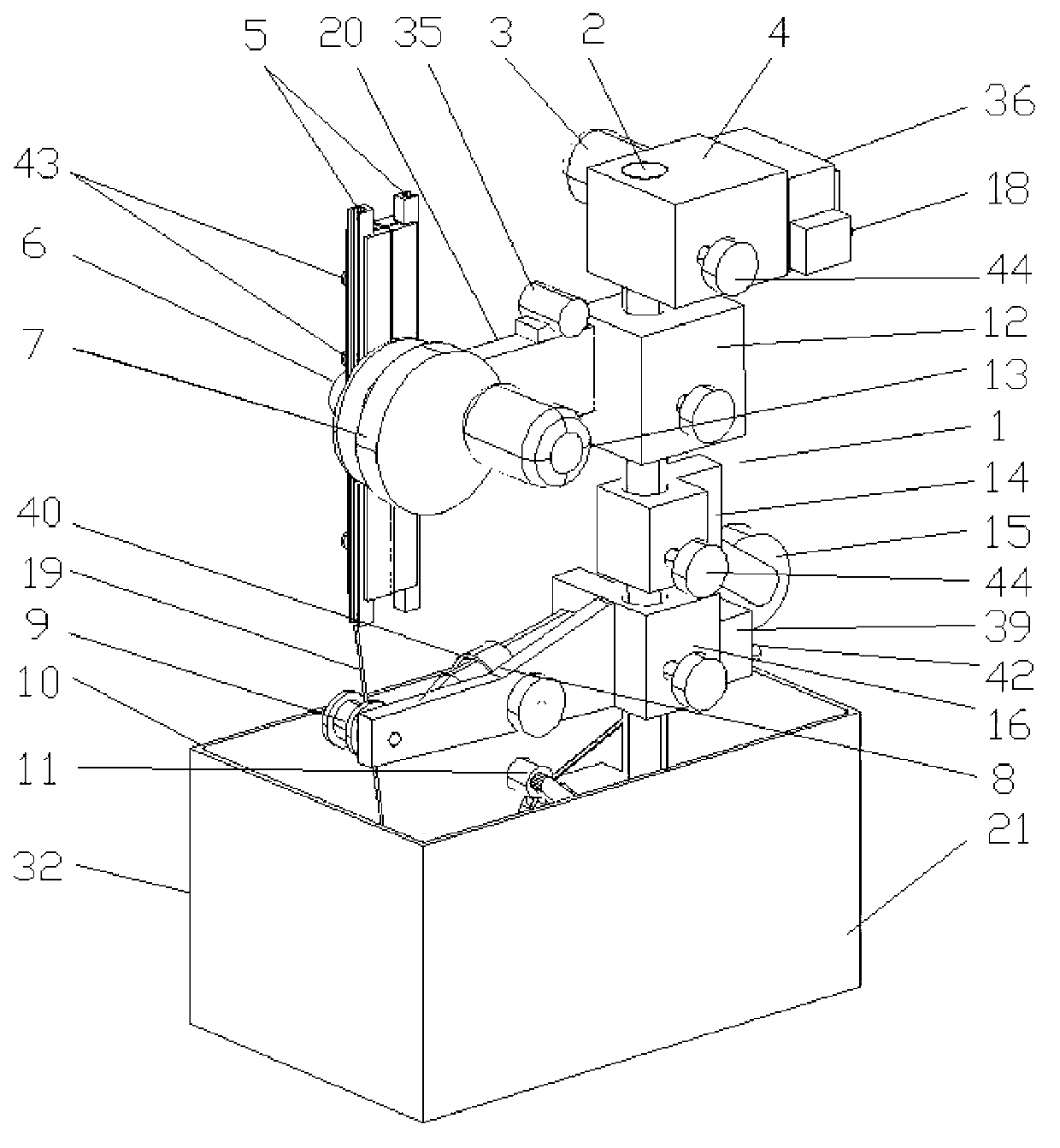

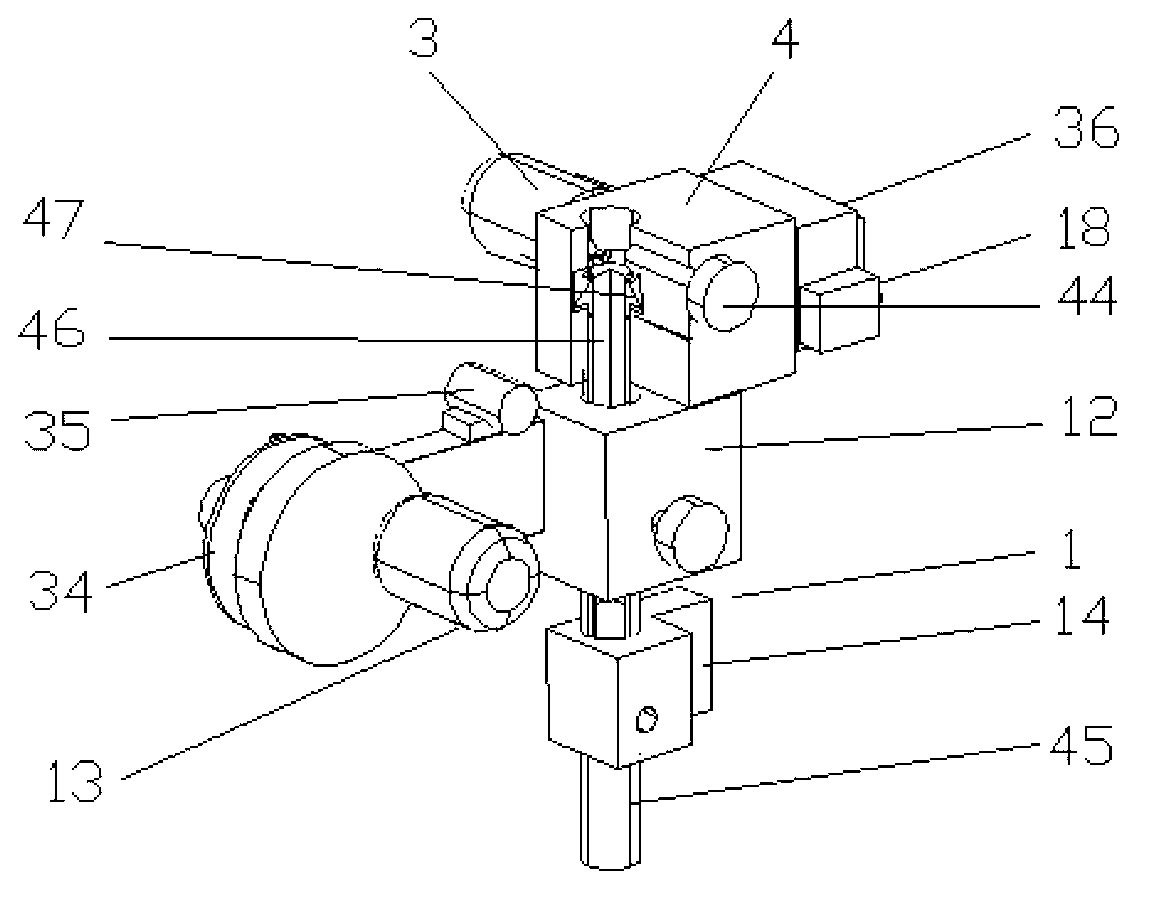

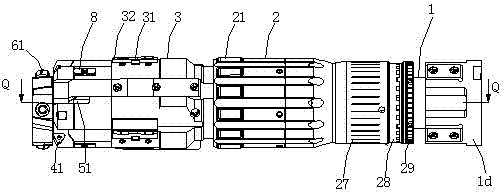

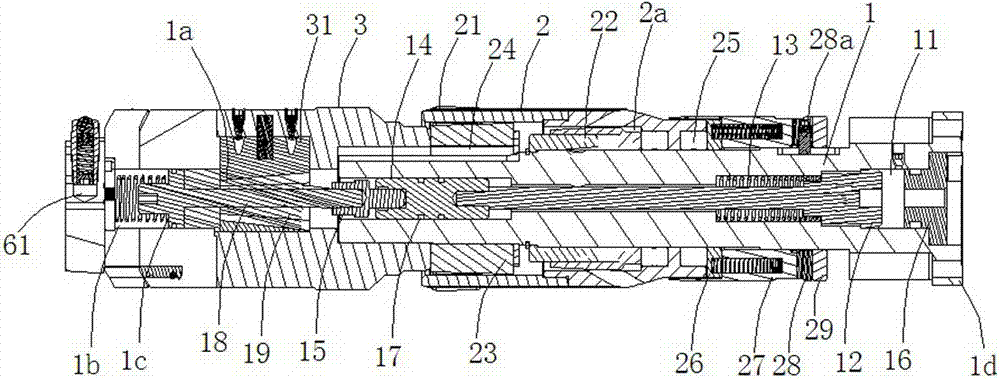

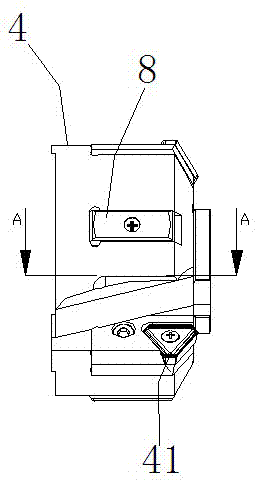

Integral advancing scraping and rolling compound cutter for flexibly boring, scraping and rolling

ActiveCN103028748AStable efficiencyEliminate errorsTurning toolsOther manufacturing equipments/toolsShape controlEngineering

The invention discloses an integral advancing scraping and rolling compound cutter for flexibly boring, scraping and rolling. A scraping head, a boring head and a rolling head are integrated, and scraping and rolling processing are performed during advancing. The integral advancing scraping and rolling compound cutter is simple in overall structure, is convenient to manufacture, and is low in cost; high-accuracy size and shape control and good guidance can be realized, scraping becomes smoother, and wave marks and errors on a processing surface of an inner hole in a previous procedure can be eliminated, so that a completed surface becomes smoother, and a better surface profile is formed; and moreover, a plurality of processing procedures are completed continuously, so that processing time is saved.

Owner:宁波市精恒凯翔机械有限公司

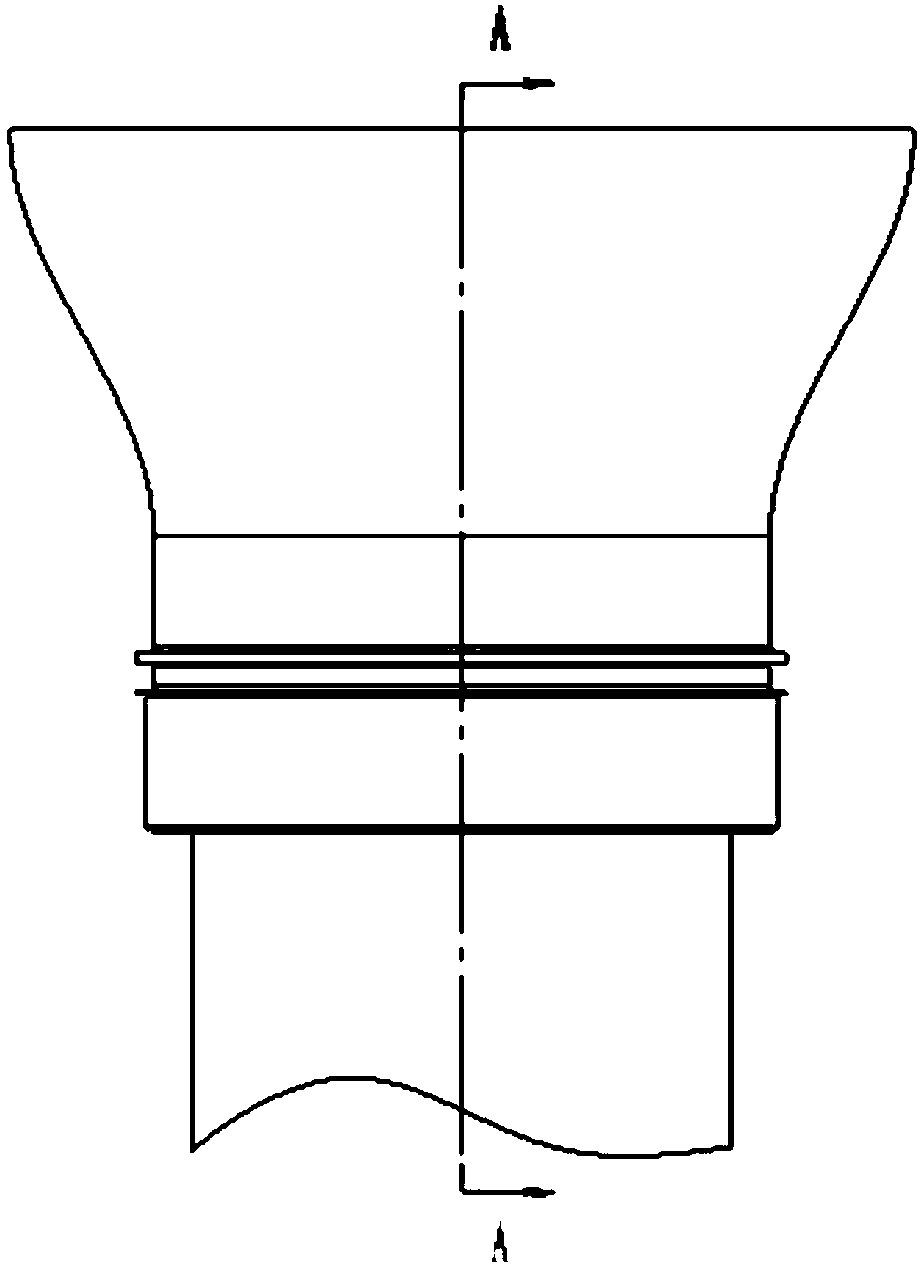

Method and fixture for controlling turning deformation of ultra-thin wall aluminum alloy high-precision nozzle sealing groove

InactiveCN109622990AAvoid clamping deformationReduce vibrationWork clamping meansTurning machinesEngineeringMachining process

The invention discloses a method and fixture for controlling a turning deformation of an ultra-thin wall aluminum alloy high-precision nozzle sealing groove. The fixture comprises an elastic expansionsleeve support body (4) with a continuously variable outer diameter, an opening expansion ring (5) and a fixture body (6); the elastic expansion sleeve support body (4) and the fixture body (6) are detachably connected; and the opening expansion ring (5) is arranged on the outer peripheral surface of the elastic expansion sleeve support body (4); and the fixture body (6) is connected to a machinetool. According to the method and the fixture, the inner hole positioning of the nozzle of a special-shaped sealing groove is utilized, and the evenly distributed clamping force in the circumferential direction when the fixture is positioned and clamped is ensured by relying on a fixture profile and the arc inner surface of the nozzle is fitly close to 360 DEG, so that the clamping deformation and turning deformation of an ultra-thin wall aluminum alloy part are avoided; and meanwhile, the direction of clamping force is symmetrically stressed with a contact point of a tool and a part during the machining process, so that the deformation of the part is effectively controlled.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

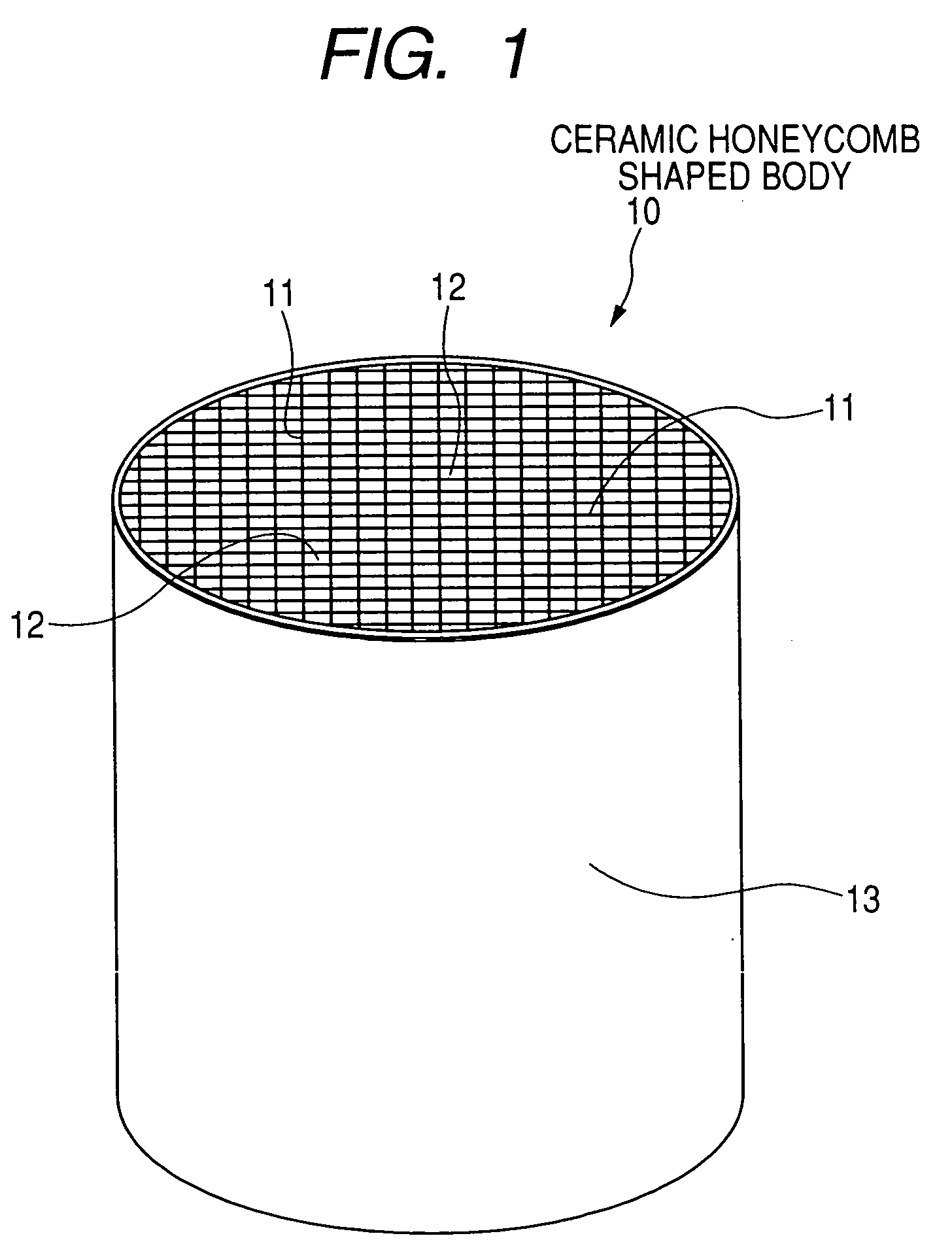

Manufacturing method of producing ceramic honeycomb structure body

InactiveUS20070096370A1Easy to produceHigh precision sizeAuxillary shaping apparatusClaywaresHoneycomb structureTissue skin

In a manufacturing method of producing ceramic honeycomb structure bodies, an extrusion molding step extrudes a ceramic raw material to make a ceramic honeycomb molded body having an outer peripheral skin part, plural cell walls arranged in a honeycomb structure shape, and plural cells surrounded by the cell walls. A cutting step cuts the ceramic honeycomb molded body into plural ceramic honeycomb shaped bodies of a predetermined length. A drying step dries each ceramic honeycomb shaped body, and a working step cuts and removes the outer peripheral part thereof. A burning step burns the worked ceramic honeycomb shaped bodies to produce the ceramic honeycomb structure bodies. In the working step, a cutting tool for blanking having a cutting tooth formed at a front part thereof is relatively moved in the axis direction of the ceramic honeycomb shaped body in order to cut and remove the outer peripheral part including at lease the outer peripheral skin part.

Owner:DENSO CORP

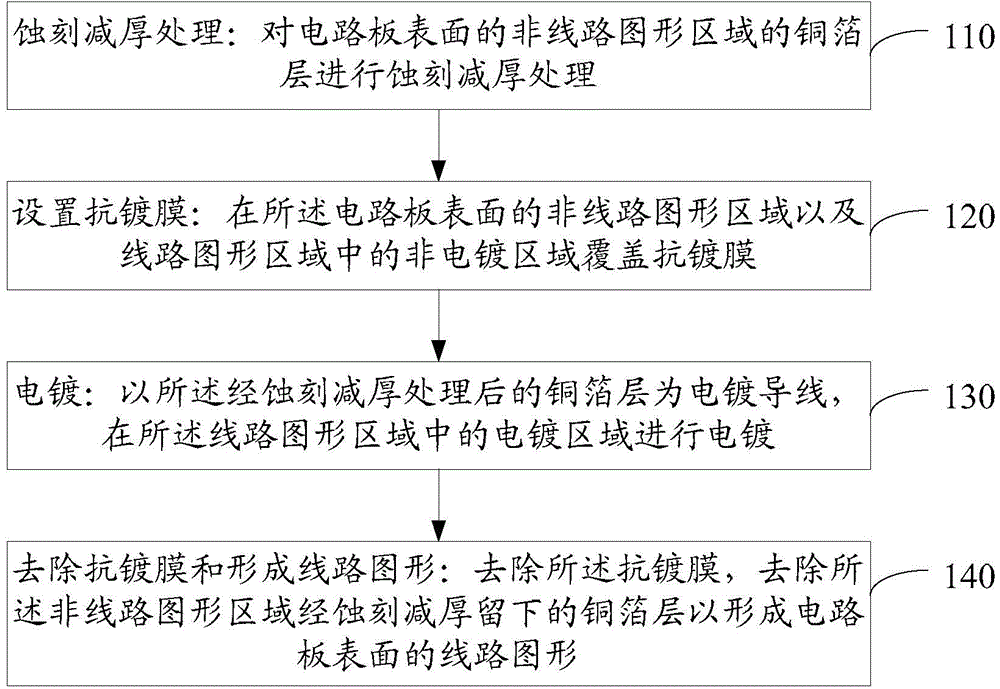

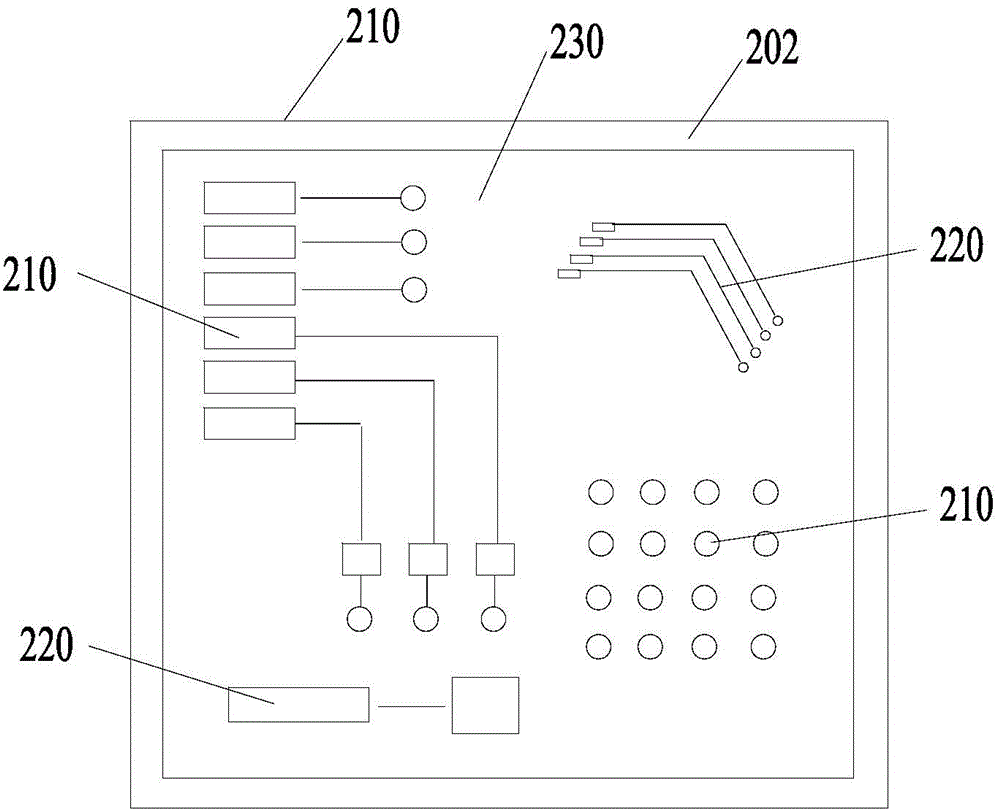

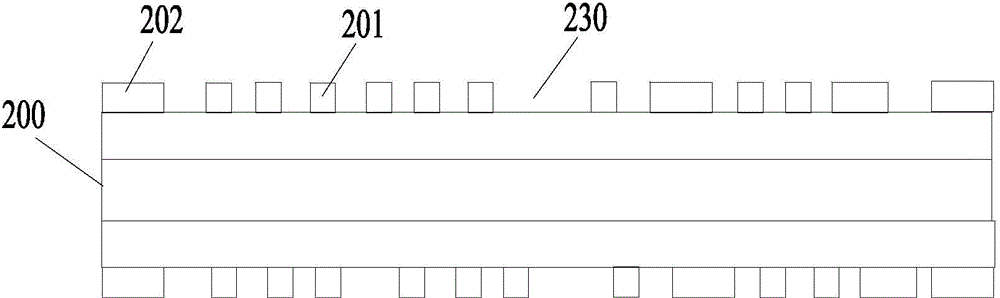

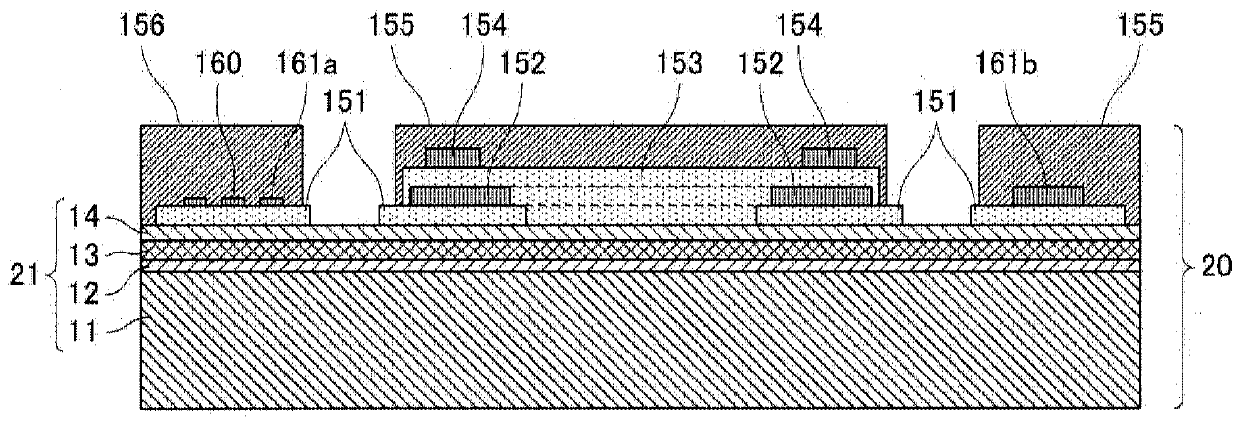

Method for electroplating surface of circuit board

ActiveCN104684265ADoes not affect accuracyHigh densityConductive material chemical/electrolytical removalEtchingReduction treatment

The invention discloses a method for electroplating the surface of a circuit board. The method comprises the following steps: performing etching thickness reduction treatment, namely performing etching thickness reduction treatment on a copper foil layer of a non-line graph region on the surface of the circuit board; arranging an electroplated film, namely covering the non-line graph region and a non-electroplated area in a line graph region on the surface of the circuit board with the electroplated film; performing electroplating, namely performing electroplating on the electroplated area in the line graph region by taking the copper foil layer subjected to the etching thickness reduction treatment as an electroplating wire; removing the electroplated film and forming a line graph, namely removing the electroplated film, and removing the copper foil layer left by etching thickness reduction in the non-line graph region to form the line graph on the surface of the circuit board. According to the technical scheme, the shortcomings of gold plating permeation, incomplete etching, collapse of a gold-plated region, short-circuit risk or the like of a conventional gold plating process are overcome; the method can be used for machining a circuit board with the requirements of high-density line and high-accuracy dimension.

Owner:SHENNAN CIRCUITS

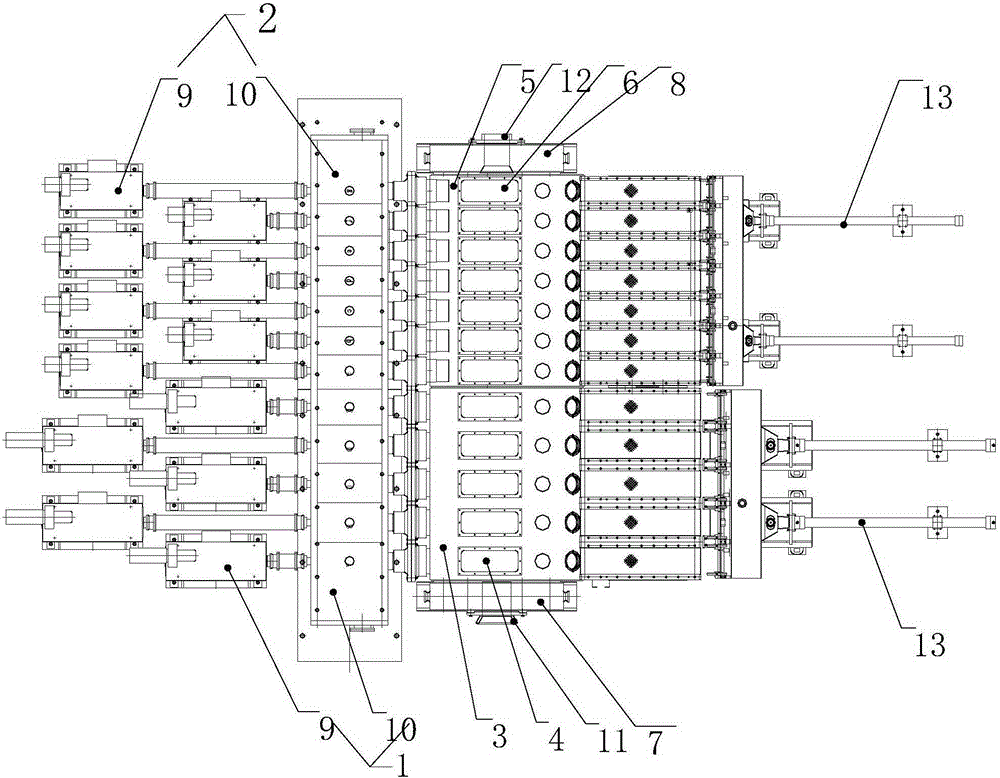

Sizing machine

ActiveCN105170658AReduce the number of replacementsQuality improvementMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

The invention relates to a sizing machine. According to the sizing machine, the number of replaced roller machine frames can be decreased, and the production cost can be saved accordingly. The sizing machine comprises first transmitting devices, second transmitting devices, a first machine base, first roller machine frames, a second machine base and second roller machine frames. The first roller machine frames and the second roller machine frames are sequentially arranged in the rolling direction of steel pipes, the first roller machine frames are fixedly arranged on the first machine base, and the second roller machine frames are fixedly arranged on the second machine base. The outer diameters of largest billet pipes which can be rolled through the first roller machine frames are larger than the outer diameters of largest billet pipes which can be rolled through the second roller machine frames. An inlet archway is arranged on the outer side face of the first machine base, and an outlet archway is arranged on the outer side face of the second machine base. Output shafts of the first transmitting devices are connected with input shafts of the first roller machine frames, the number of the second transmitting devices is equal to the number of the second roller machine frames, and output shafts of the second transmitting devices are connected with input shafts of the second roller machine frames.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

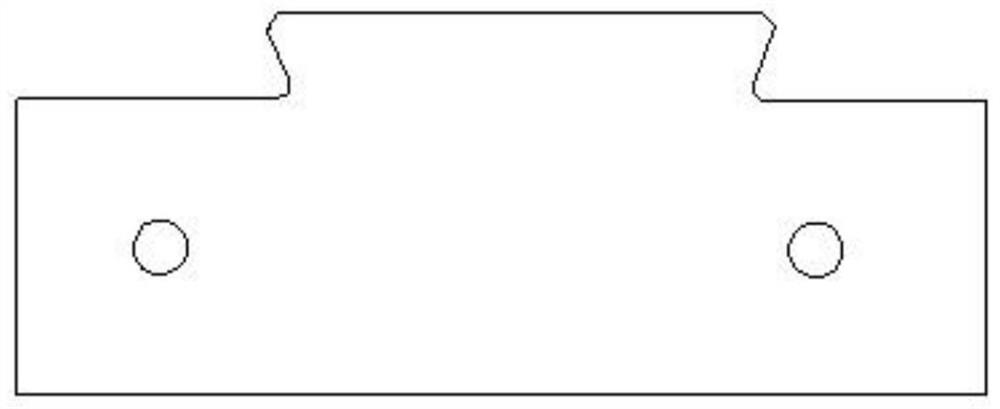

Method for manufacturing memory alloy spacecraft unlocking drive element

ActiveCN103343309ASimple processEasy to implementCosmonautic vehiclesCosmonautic partsShape-memory alloyAlloy

The invention discloses a method for manufacturing a memory alloy spacecraft unlocking drive element. The method comprises the following steps of: cooling a drive element blank and a mold to be below a phase transformation point Mf of a drive element material; pressing the drive element blank in the mold, thus obtaining the spacecraft unlocking drive element. The mold comprises an upper pressing plate, a lower pressing plate, and a clamp, wherein a central hole is formed between the upper pressing plate and the lower pressing plate and is used for accommodating the drive element blank; positioning tanks or positioning tables are respectively arranged on the upper pressing plate and the lower pressing plate for matched positioning. The manufacturing method refers to manufacturing the drive element by compressing a high-precision shape memory alloy bar billet in a detachable mold, and is simple, feasible, convenient in detachment and low in preparation cost; one-step preparation of multiple elements with the axis ratio of less than 5 (the ratio of the length to diameter is less than or equal to 5) can be realized. The drive element prepared by the manufacturing method is uniform in deformation, high in dimensional accuracy and high in drive resilience and recovery strain.

Owner:西安赛特新材料科技股份有限公司

Cylinder apparatus and disk brake

ActiveUS8083035B2High precision sizeReduce processing costsValve arrangementsAxially engaging brakesMechanical engineeringPiston

A method of manufacturing a cylinder apparatus wherein although an opening of a cylinder body is closed by a covering member, processing and parts costs are reduced, fluid leakage is prevented, and the apparatus can be reduced in size. The cylinder apparatus includes a piston (17) which is caused to slidingly move in a bore (26) of a cylinder (21). The cylinder 21 includes a covering member (43) provided in a bottom portion (42) of the cylinder (21), and a cylinder body (46) having an opening that is closed by the covering member (43). The covering member (43) is friction stir welded to the cylinder body (46).

Owner:HITACHI ASTEMO LTD

Method for machining chip mounter guide rail seat through gantry pentahedron numerical control machine tool

InactiveCN104439897AReduce investmentHigh precision sizeMeasurement/indication equipmentsPositioning apparatusStructural engineeringPentahedron

The invention discloses a method for machining a chip mounter guide rail seat through a gantry pentahedron numerical control machine tool. The method comprises the steps that the gantry pentahedron numerical control machine tool is firstly utilized for carrying out rough machining on a green body and machining the faces, corresponding to groove opening faces, of the green body to form a rough locating face; then, the green body is located and clamped with the rough locating face in the first procedure as the datum, side face semifinishing is carried out on the machine tool, and finish machining is carried out on the face corresponding to the rear side face to form a first locating face; the green body is located and clamped again with the first locating face as the standard, rough machining is carried out on the faces corresponding to the inner side groove faces of a sliding groove through the machine tool, and finish machining is carried out on the face corresponding to the lower bottom faces of connecting portions of the green body and the face corresponding to the front side faces of the connecting portions to form a second locating face and a standard face respectively; finally, the green body is located and clamped again with the second locating face as the fine datum face, and finish machining is carried out on holes and the faces corresponding to all the inner side groove faces of the sliding groove. The high-precision size can be machined successfully, and it is guaranteed that the machining quality of the chip mounter guide rail seat is stable 100 percent.

Owner:SUZHOU IND PARK ELECTROMECHANICAL EQUIP

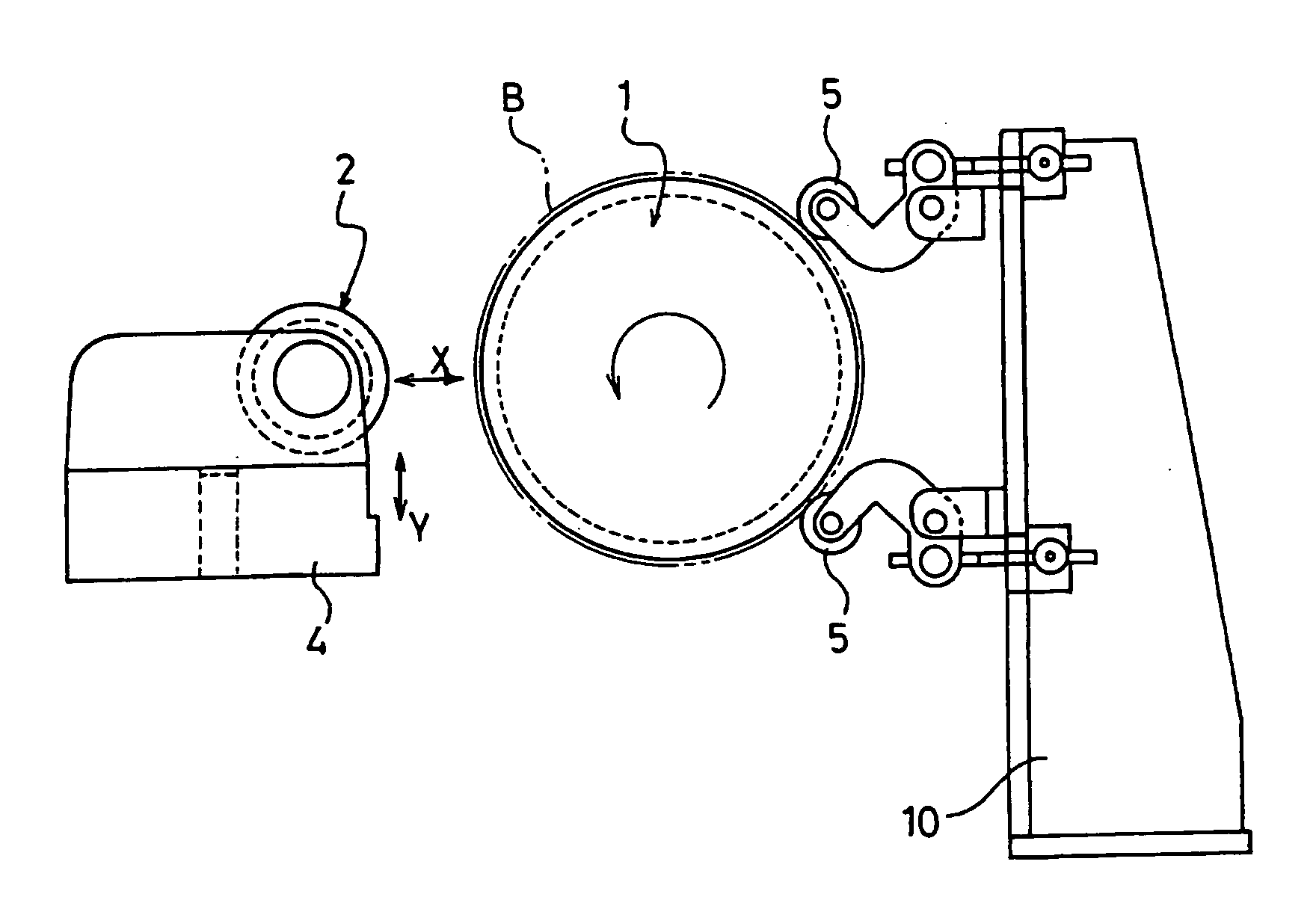

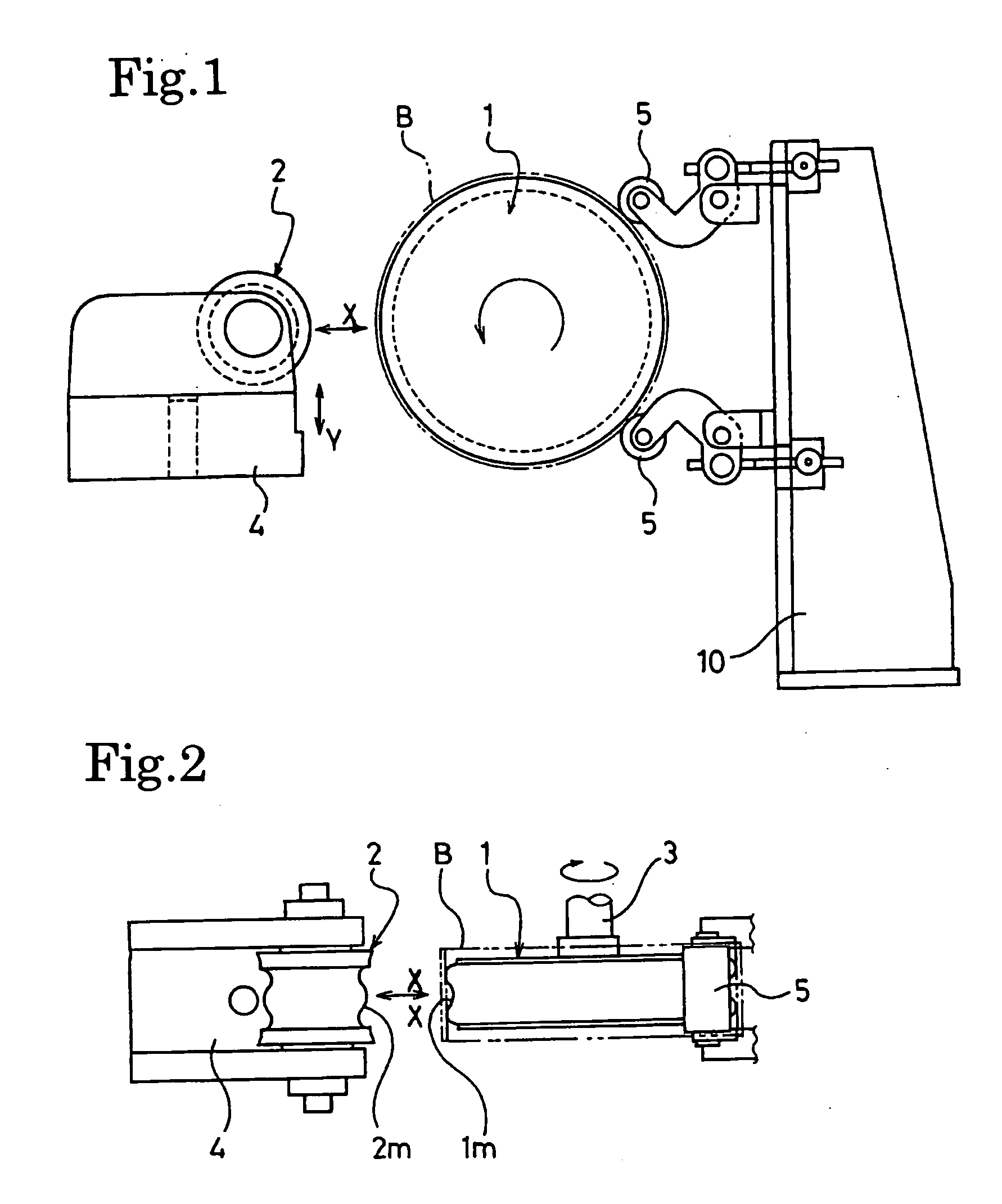

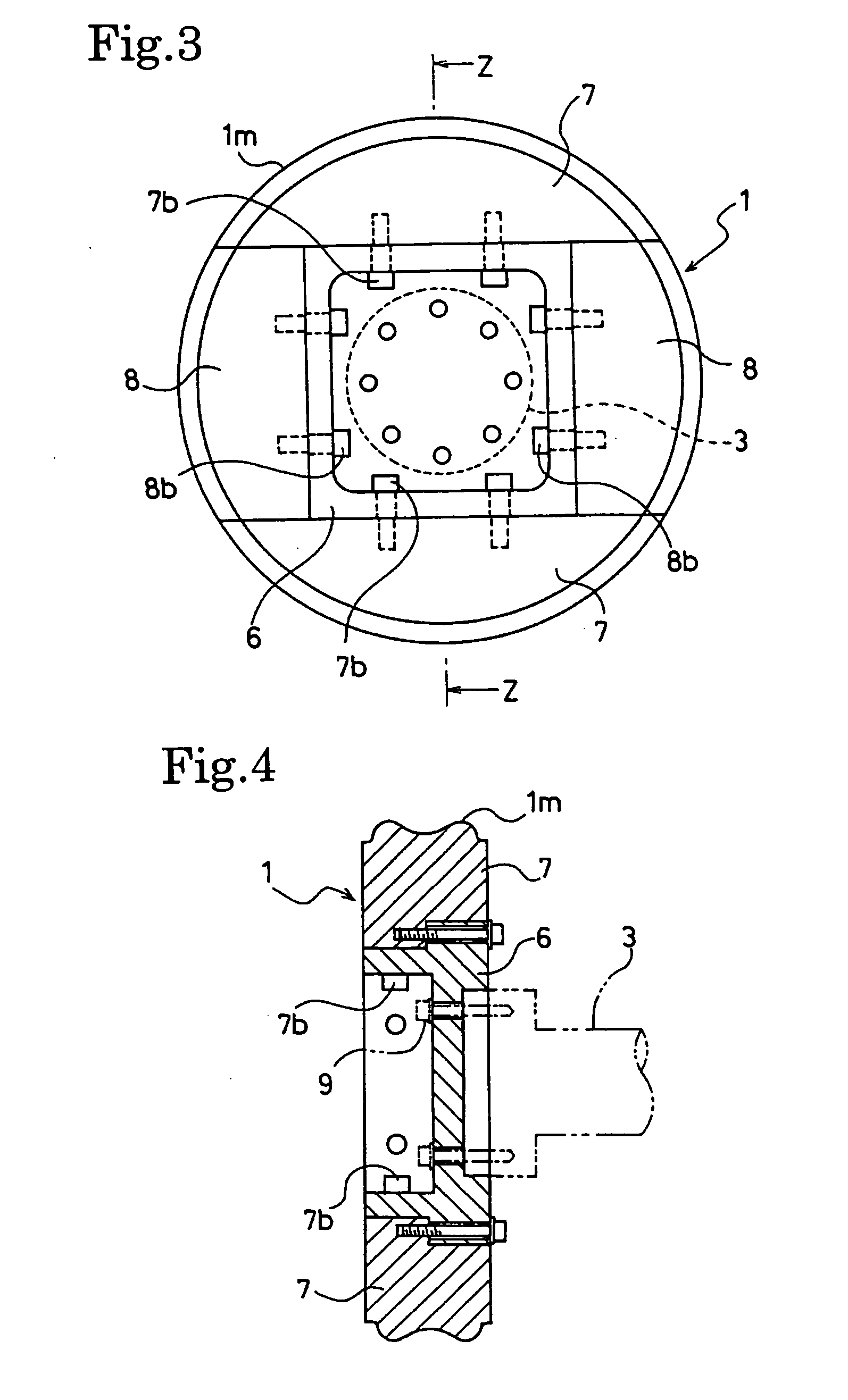

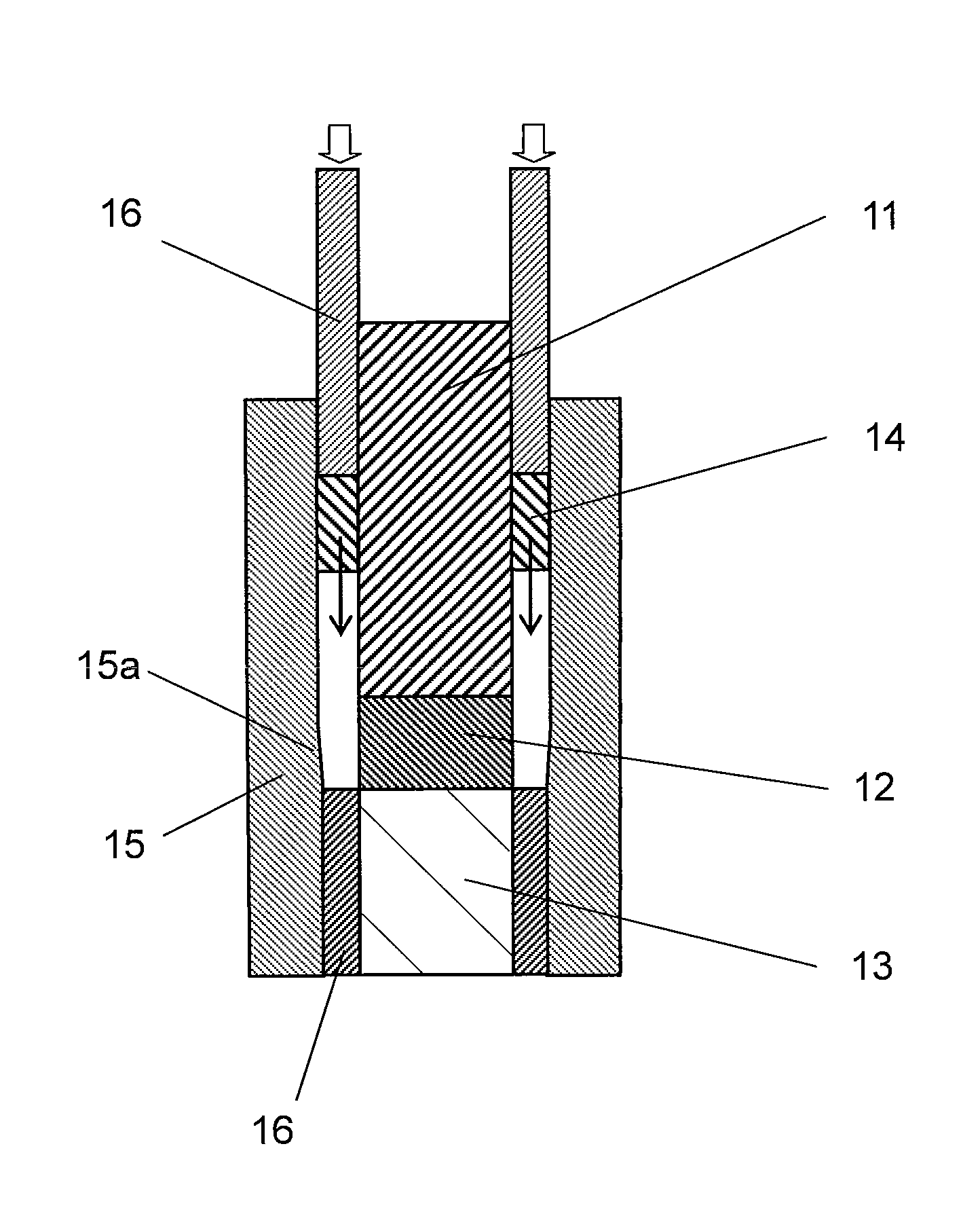

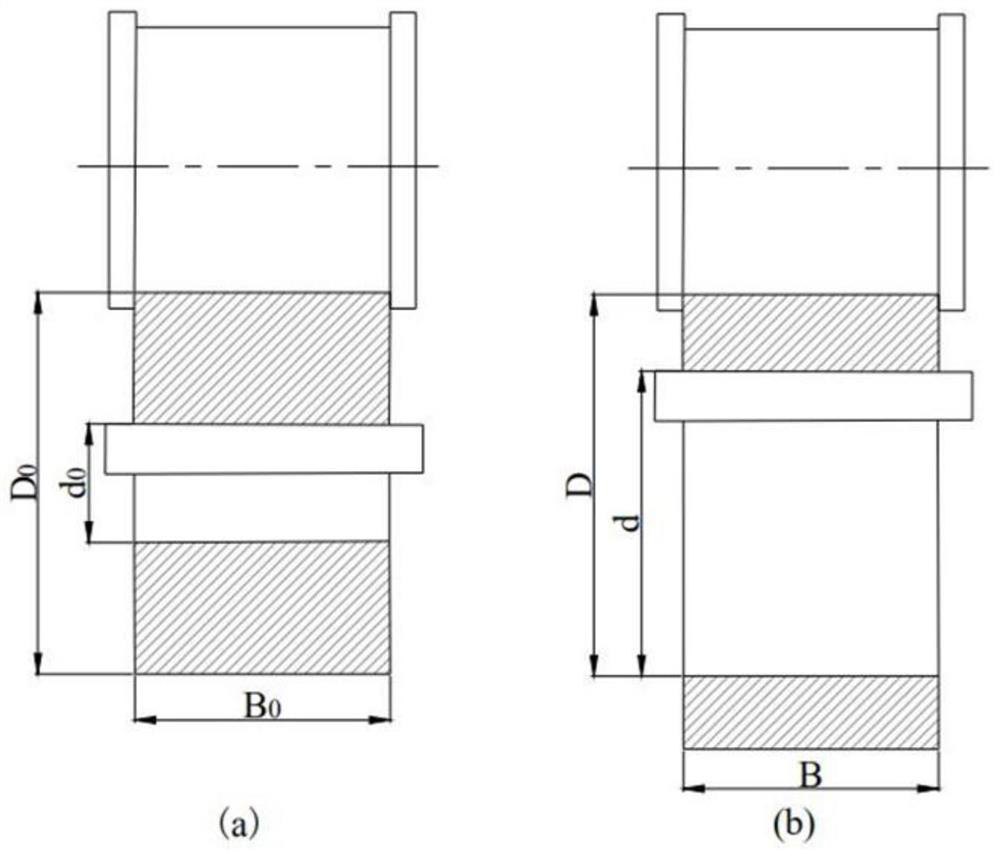

Method and device for manufacturing support body for run flat

A method of manufacturing a support body for run flat, wherein in a case where the circumferential wall of a tubular blank B is pressingly held between inner and outer molding rollers 1 and 2 and where the molding rollers 1 and 2 are rotated to form at least one circumferentially continuous protruding part on the circumferential wall of the tubular blank B to process the tubular blank B into an annular shell, a molding roller having the maximum outer diameter that is substantially the same as the inner diameter of the tubular blank B is used as the inner molding roller 1.

Owner:YOKOHAMA RUBBER CO LTD

Surface treatment of molded resin products

InactiveCN1613634ADamage to dimensional accuracyHigh precisionPretreated surfacesCoatingsAdhesion strengthGrindstone

The object of the present invention is to provide a method for surface treatment of resin molded products, which improves the adhesion strength between the surface of resin molded products that are difficult to print and coat, ink and paint, and does not damage the resin molded products. Dimensional accuracy. The specific method is to add resin moldings that are not easy to print and apply, grinding stones, and water into the treatment tank to make them flow in a vortex shape. By colliding the resin moldings with the grinding stone, ten parts of the resin molding surface can be removed The point average roughness is roughened to 10μm~40μm.

Owner:SUMITOMO RUBBER IND LTD

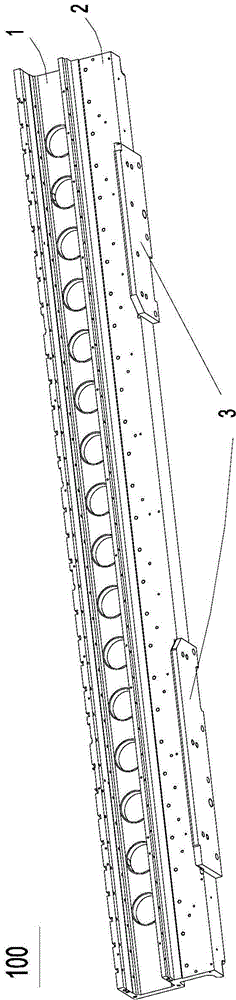

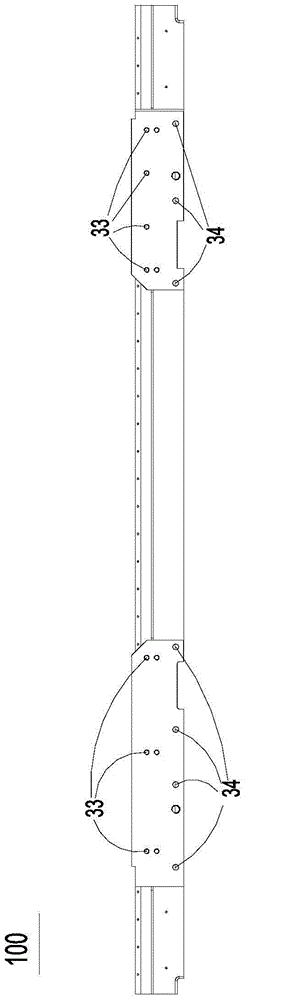

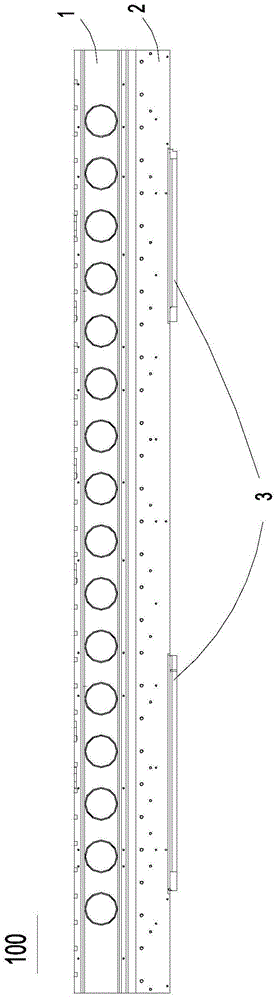

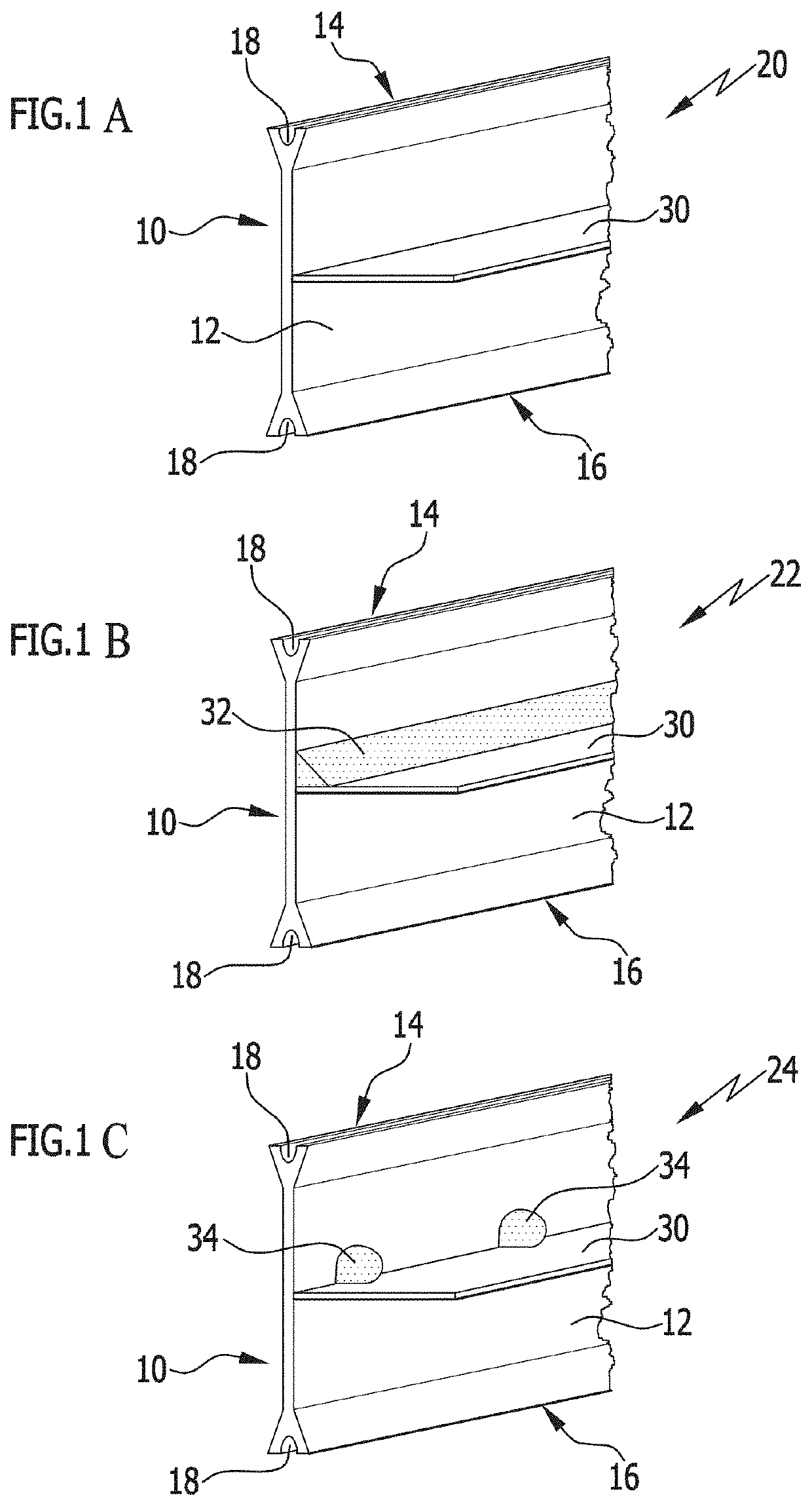

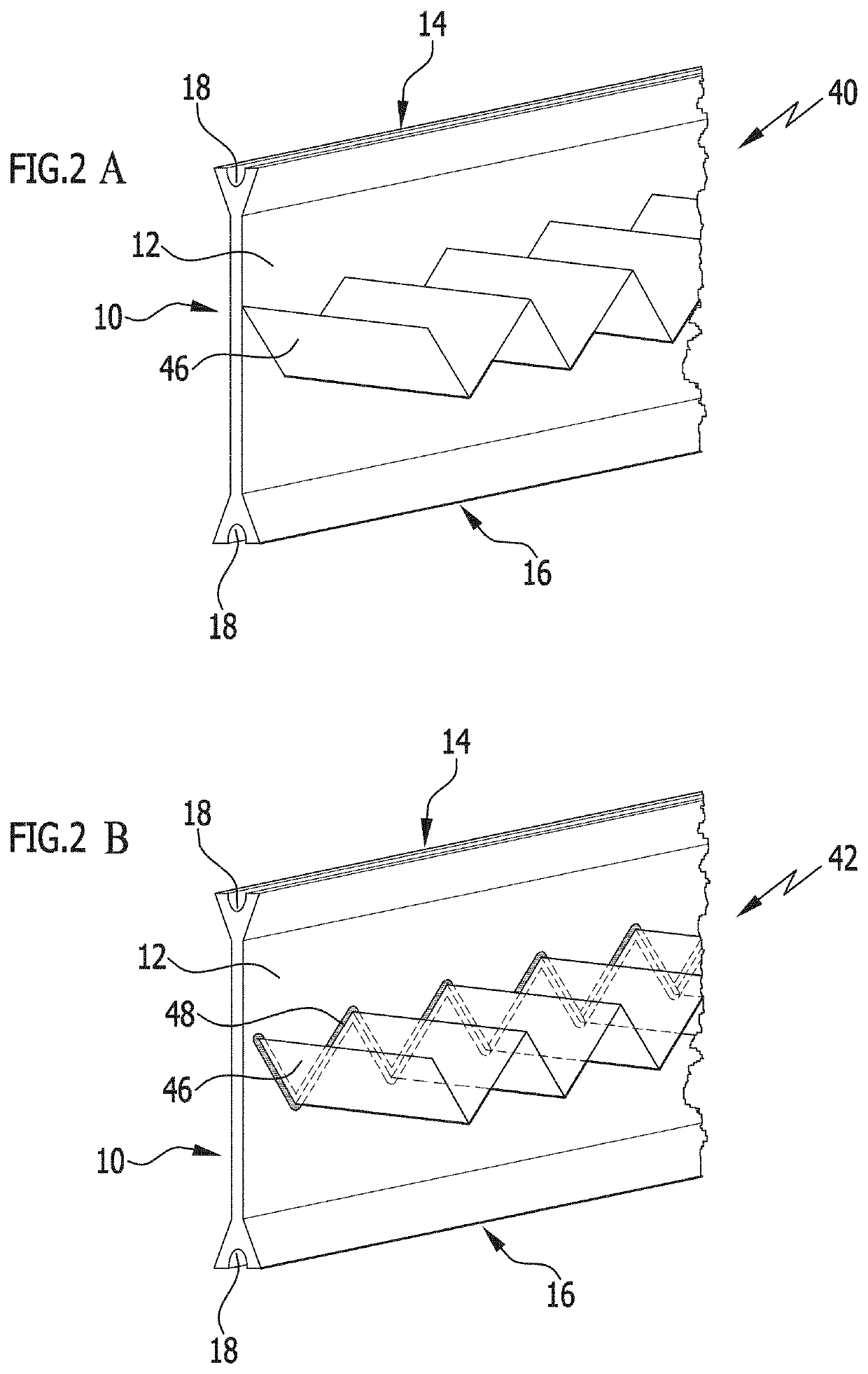

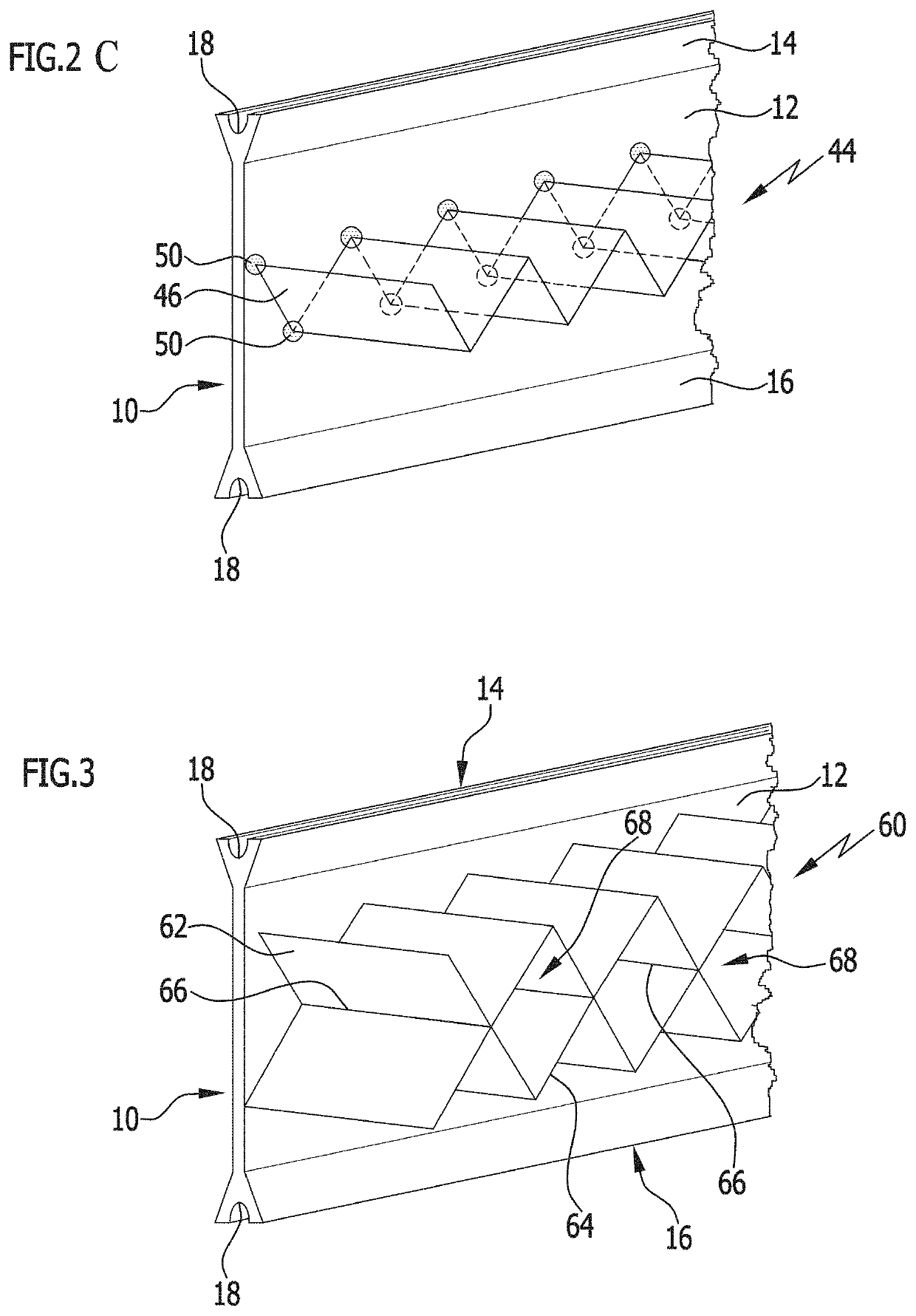

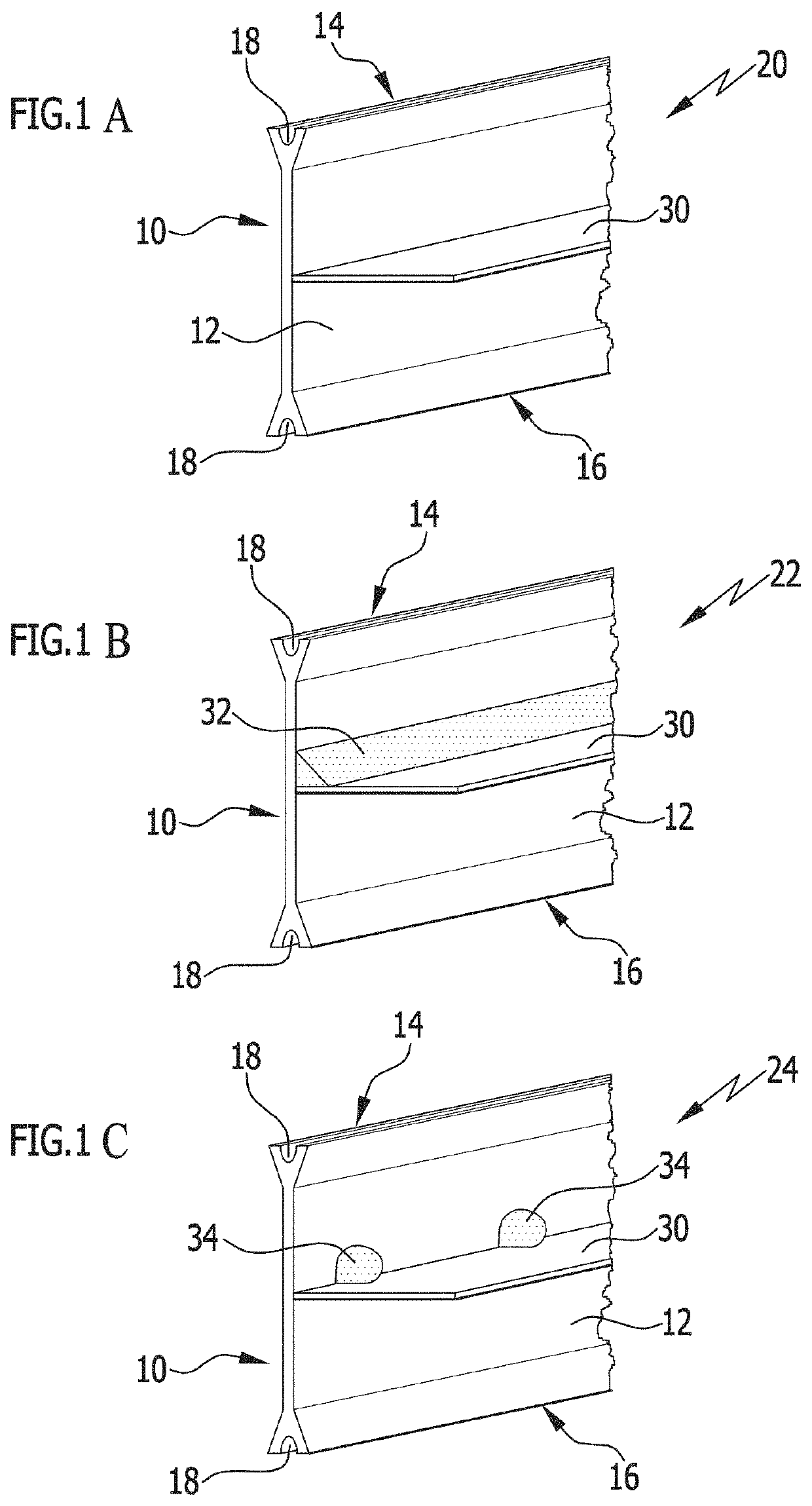

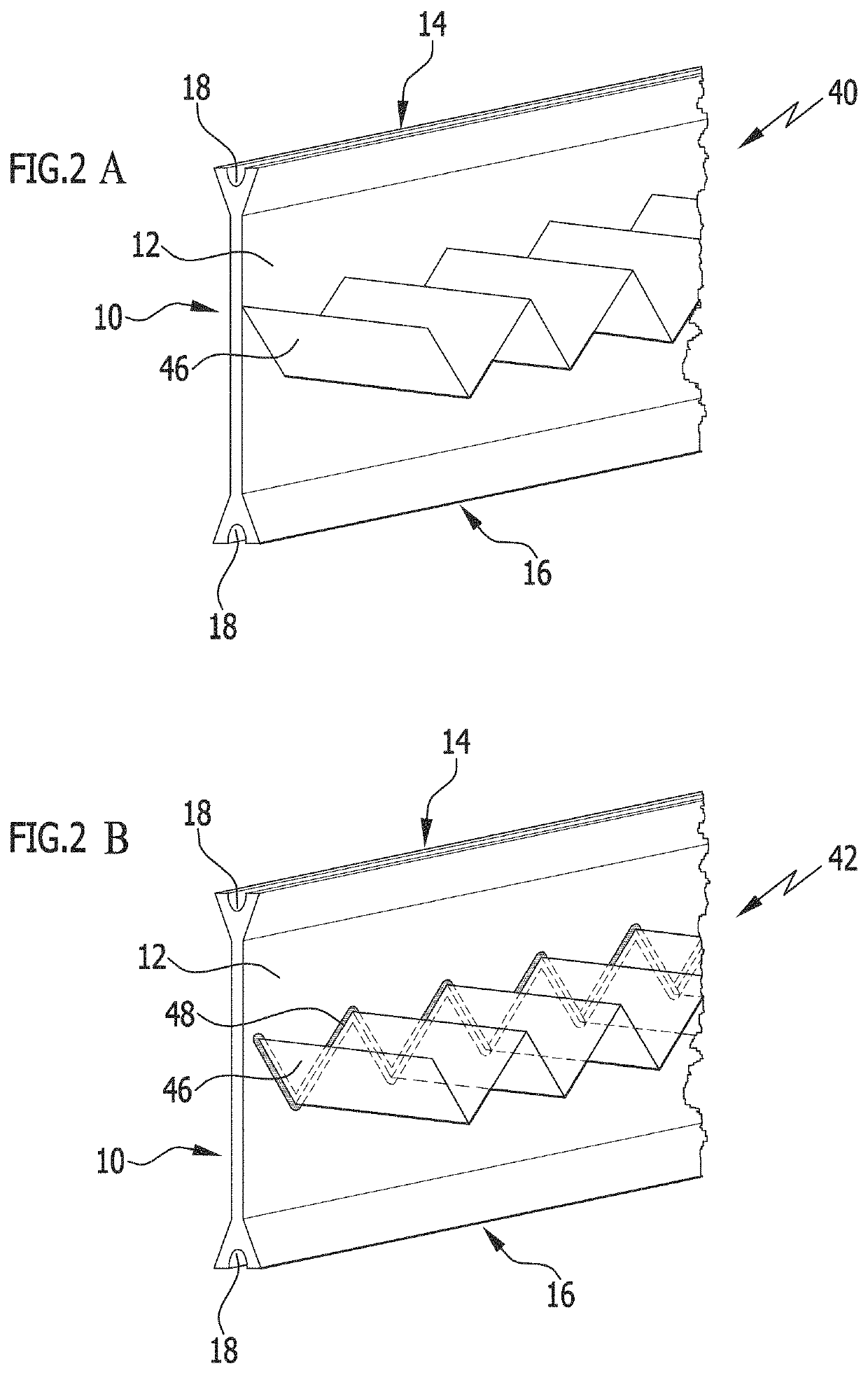

Insulating profile, in particular for the production of window, door, and facade elements, and methods for the production thereof

ActiveUS20200071986A1Wide rangeMinimizes tooling costDoors/windowsDomestic articlesPolymer scienceMechanical engineering

The invention proposes insulating profiles of a polymer material, and methods for producing the insulating profiles, are disclosed

Owner:ENSINGER

Magnetic wave instrument magnetic core forming machine

InactiveCN103280307AReduce mechanical deformationReasonable design structureInductances/transformers/magnets manufactureWinding machineSolution agitator

The invention discloses a magnetic wave instrument magnetic core forming machine which comprises a heat treating forming groove frame combination device for a rod-shaped magnetic core, a lifting column device, a magnetic core tape winding machine magnetic core tape coating fluid container groove, a hot-air drying device and the like. The heat treating forming groove frame combination device for the road-shaped magnetic core is composed of a straight-groove-shaped magnetic core forming groove frame, a pressing plate and a forming groove combination device. The rod-shaped magnetic core is located in a straight groove and pressed tightly by the pressing plate and the combination device, wherein the width of the pressing plate is same as that of the straight groove. Moreover, the magnetic wave instrument magnetic core forming machine comprises a rotating device, an alignment clamping device, a submerged rolling shaft and a raw material rolling shaft support. The magnetic core tape winding machine magnetic core tape coating fluid container groove is composed of a rectangular hexahedron type plastic container groove, wherein the lifting column device and a liquor stirrer are installed at the bottom of the plastic container groove. The hot-air drying device is a magnetic core tape coating quick-drying device which is located above the liquor level of the magnetic core tape coating fluid container groove and fixed in the middle of a lifting column with a hot-air blower as a body.

Owner:NAT SPACE SCI CENT CAS

Insulating profile, in particular for the production of window, door, and facade elements, and methods for the production thereof

ActiveUS11072970B2High precision sizeImprove parallelismDoors/windowsDomestic articlesPolymer scienceMechanical engineering

The invention proposes insulating profiles of a polymer material, and methods for producing the insulating profiles, are disclosed.

Owner:ENSINGER

Method of manufacturing in-mold decorative molded article

ActiveCN110126180AHigh precision sizeImprove designDecorative surface effectsCoatingsClear LayerInjection moulding

A method of manufacturing an in-mold decorative molded article capable of transferring a decorative pattern with target dimensions at a target position of a decorative molded article according to thepresent disclosure includes supplying an in-mold transfer foil to a metal mold, in which a clear layer having transparency and lower extensibility than a base material film is formed in the first layer on an in-mold raw fabric configured by forming a mold releasing layer and a primer layer on the base material film and a decorative figure is printed in the second and subsequent layers on the in-mold raw fabric, clamping the metal mold, injecting and cooling a molding resin and taking out an molded article formed of the molding resin cooled and cured in the metal mold in which the clear layer and a transfer layer having the decorative figure in the in-mold transfer foil are integrated on the surface by opening the mold, molding the molded article integrally with a cutting portion not necessary for a target product inside the metal mold by the molding resin at an outer periphery of the product and arranging a boundary of a printing region of the clear layer in the in-mold transfer foil in the cutting portion so as to be larger than the outer periphery of the product.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

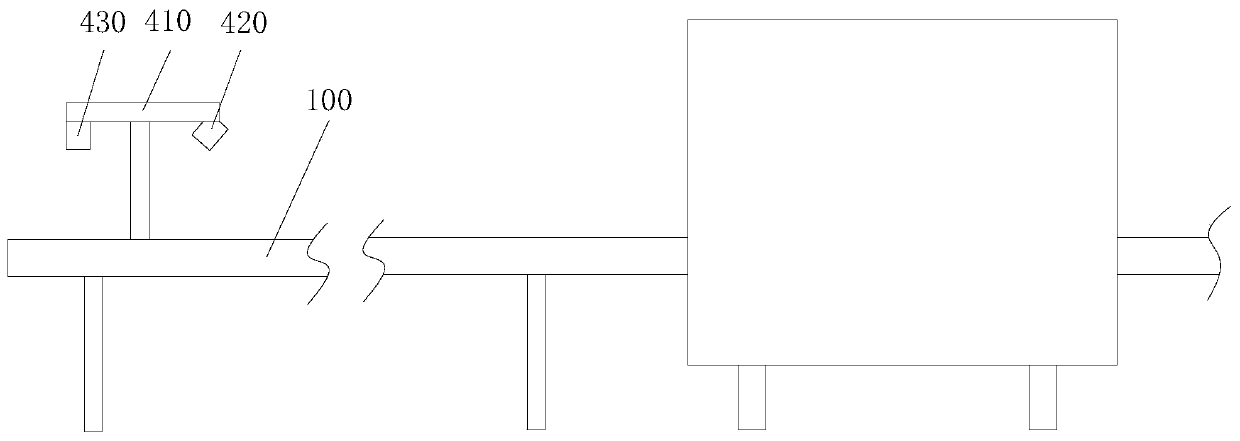

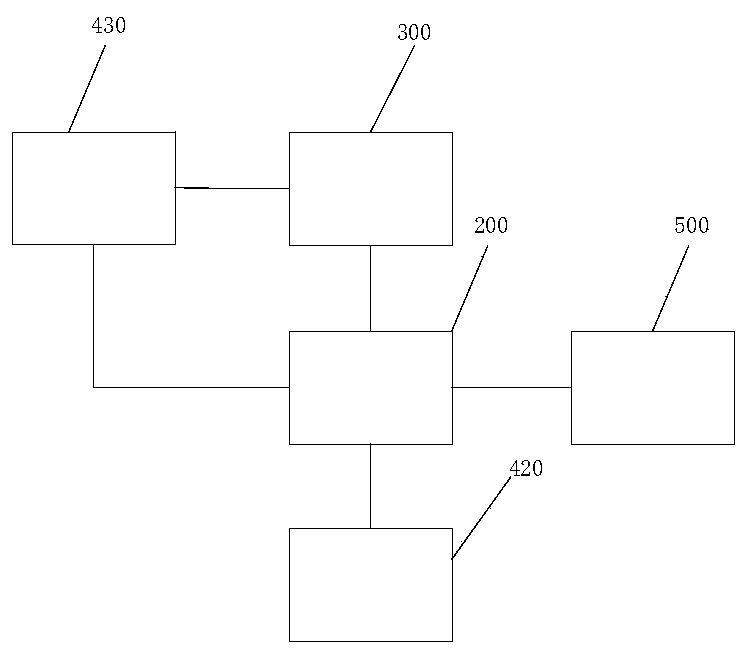

Automatic longitudinal-cutting system for corrugated boards

InactiveCN109968456AIncrease profitHigh precision sizeCircular sawsGauging meansMeasurement deviceEngineering

The invention discloses an automatic longitudinal-cutting system for corrugated boards, and belongs to the field of plate cutting, particularly wood plate cutting. A disc multi-blade saw body is applied, and the system further comprises a controller, an industrial personal computer 300 and an online measuring device arranged on a conveying roller bed. By the aid of the online measuring device, during advancing of the boards, sizes of the boards are detected in real time, the widths of minimum rectangles of the boards are calculated, and then a driving device is controlled to automatically adjust the position of blades for sawing. The system has the beneficial effects that the board utilization rate is high, the working efficiency is high, the labor intensity is reduced, and the labor costis reduced.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

Method of manufacturing in-mold decorative molded article

ActiveUS11007689B2High precision sizeStrong designabilityDecorative surface effectsCoatingsComposite materialClear Layer

A method of manufacturing an in-mold decorative molded article includes supplying an in-mold transfer foil to a metal mold, injecting and cooling a molding resin and taking out an molded article formed of the molding resin cooled and cured in the metal mold in which a clear layer and a transfer layer having a decorative figure in the in-mold transfer foil are integrated on the surface by opening the mold, molding the molded article integrally with a cutting portion not necessary for a target product inside the metal mold by the molding resin at an outer periphery of the product and arranging a boundary of a printing region of the clear layer in the in-mold transfer foil in the cutting portion so as to be larger than the outer periphery of the product.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

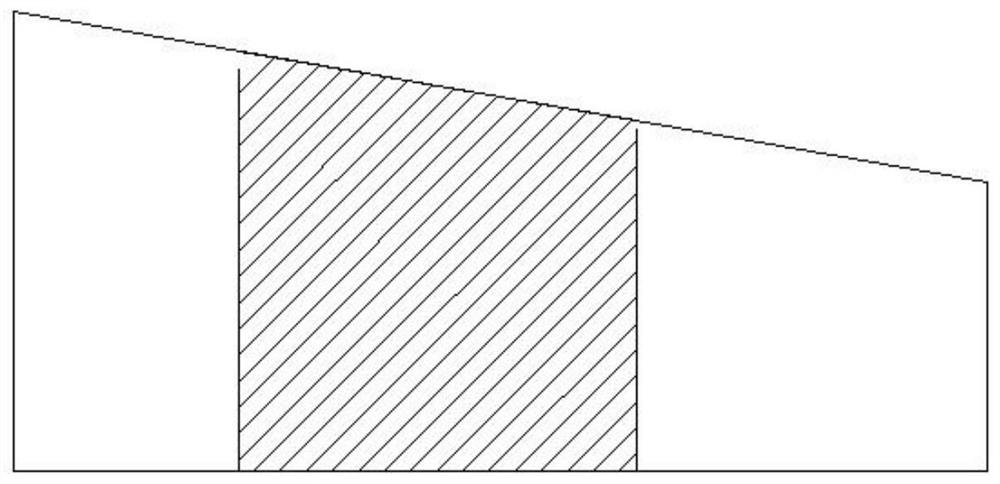

A kind of processing method of wedge-shaped plate forging

ActiveCN111644551BReduce forging allowanceQuality improvementForging/hammering/pressing machinesForging press drivesMetal fiberWedge angle

The invention discloses a processing method for a wedge-shaped plate forging, which belongs to the technical field of steel forging and forming. The problem to be solved by the present invention is to reduce the production cost of the wedge-shaped plate. The technological process of the present invention is steel ingot heating → jaw pressing → chamfering → bottom removal of ingot → first upsetting → first drawing of rectangular blank → second upsetting → second drawing of rectangular blank → third drawing Rectangular blank→half-die forging with special upper anvil→heat treatment→finishing each part to the finished product size, the special upper anvil is an upper flat anvil, and the angle between the bottom edge of the upper flat anvil and the horizontal plane is less than or equal to the wedge angle of the wedge plate forging. The present invention adopts two upsetting and two drawing forging forming while changing from the traditional round but not square to square forging process breakthrough. The special flat anvil is used for the final fire finishing, and the special tool is used for forging forming to make the wedge-shaped plate forging qualified at one time. The rate reaches more than 95%, the metal fiber streamline is better, the operation is simple, and the weight of the forging blank process is reduced. The invention is used for processing wedge-shaped plate forgings.

Owner:建龙北满特殊钢有限责任公司

Surface treatment of molded resin products

InactiveCN100434259CDamage to dimensional accuracyHigh precisionPretreated surfacesCoatingsPrinting inkAdhesion strength

The invention aims to provide a surface treatment method for a resin molded product enhancing adhesion strength of a printing ink or a coating in the surface of the resin molded product having hardly printing property or hardly coating property and not impairing dimensional precision of the resin molded product. The resin molded product having the hardly printing property or the hardly coating property, a polishing stone and water are thrown into a treatment vessel and are made to flow in a form of whirlpool and the resin molded product and the polishing stone are made to collide. Thereby, roughening of ten-point average roughness of surface of the resin molded product is carried out to 10 [mu]m-40 [mu]m.

Owner:SUMITOMO RUBBER IND LTD

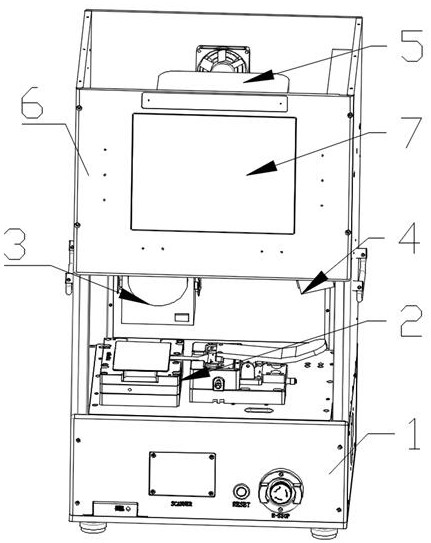

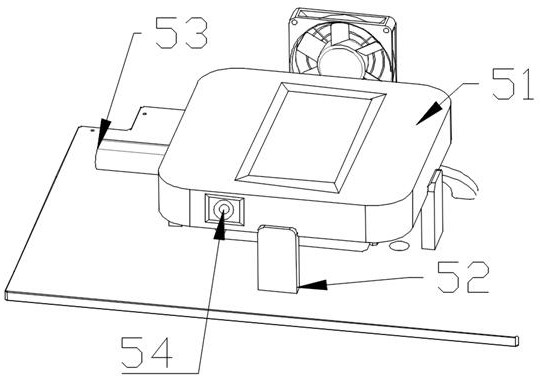

A fully automatic laser scanning tester

ActiveCN111272080BMeet needsReduce labor burdenUsing optical meansDeodrantsTester deviceLaser scanning

The invention discloses a fully automatic laser scanning tester, which comprises a frame, a scanning device, a material loading device, a first plasma fan, a second plasma fan, a testing device and a receiving device. The scanning device is arranged on the frame Inside, the loading device is set on the frame, a test cover is set above the loading device, the bottom of the test cover is set on the frame, and a test device is set on the top of the test cover. A receiving device is arranged on the test device, the receiving device is connected to the test device, a first plasma fan and a second plasma fan are respectively arranged in the test cover, and the fixed end of the first plasma fan is arranged on the rear side of the test cover , the fixed end of the second plasma fan is set on the right side of the test cover, a display screen is set on the front side of the test cover, and the test device is connected to the display screen to reduce production costs, reduce production efficiency, and have high precision dimensions , has good market application value.

Owner:SHENZHEN SMART HENGDI TECH CO LTD

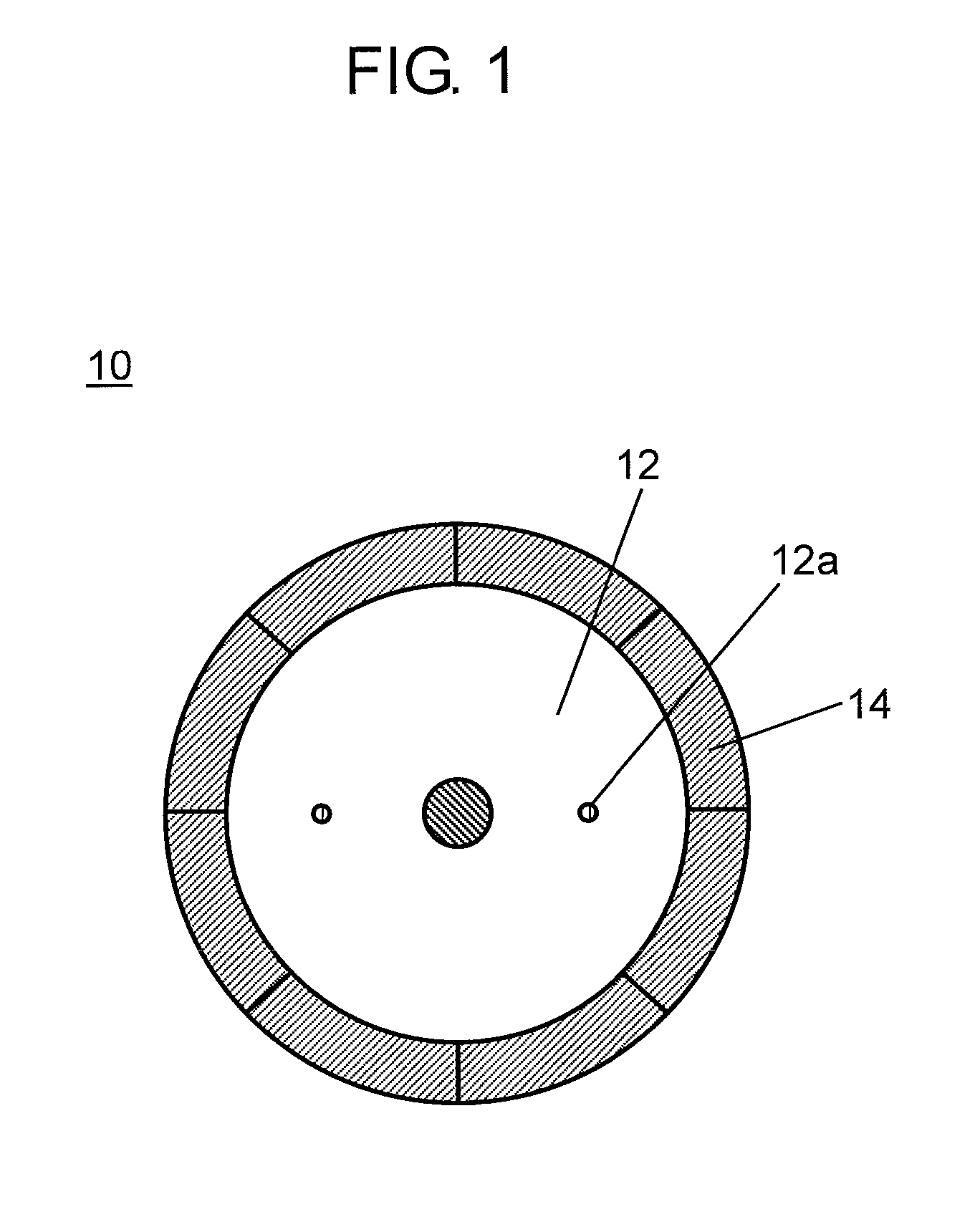

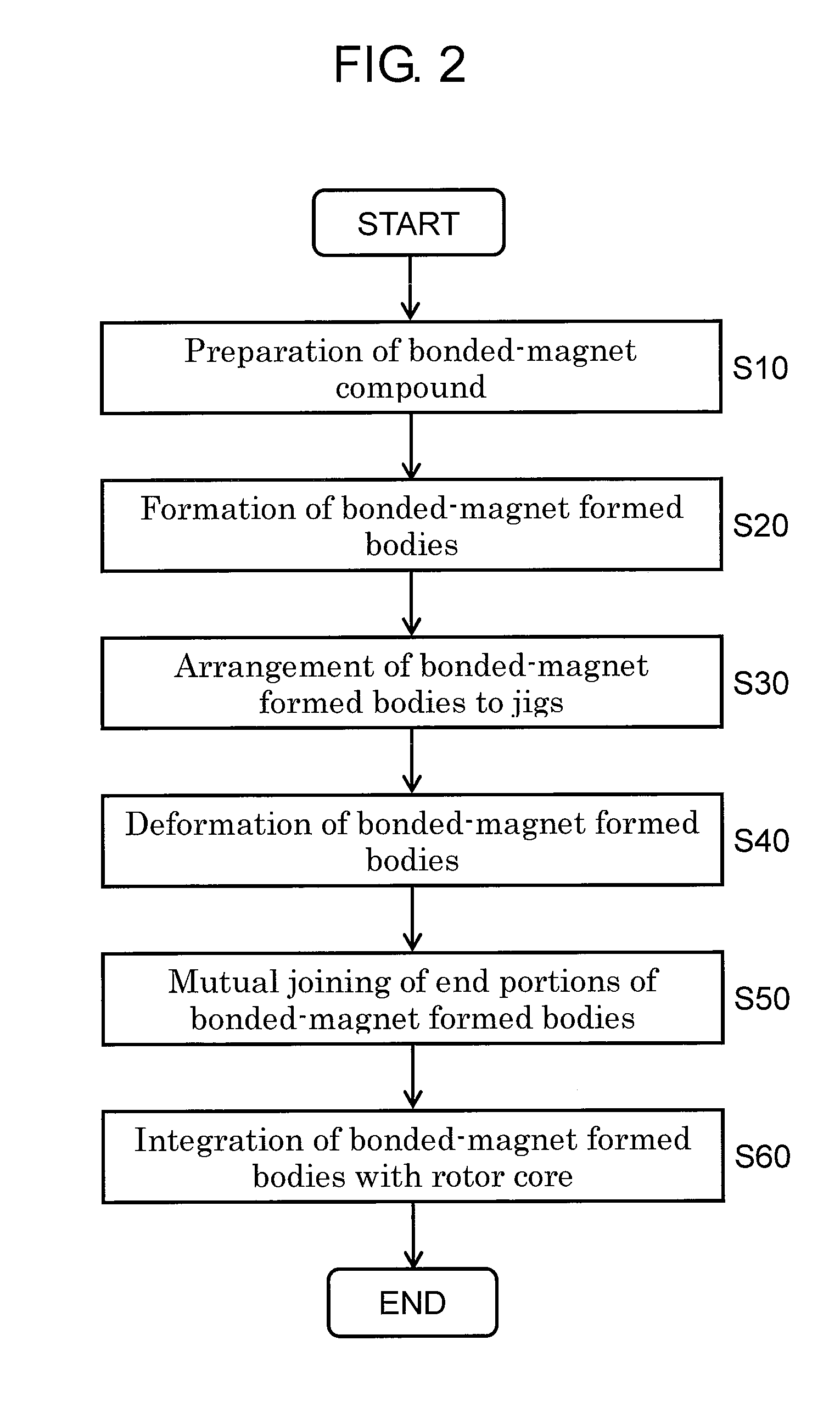

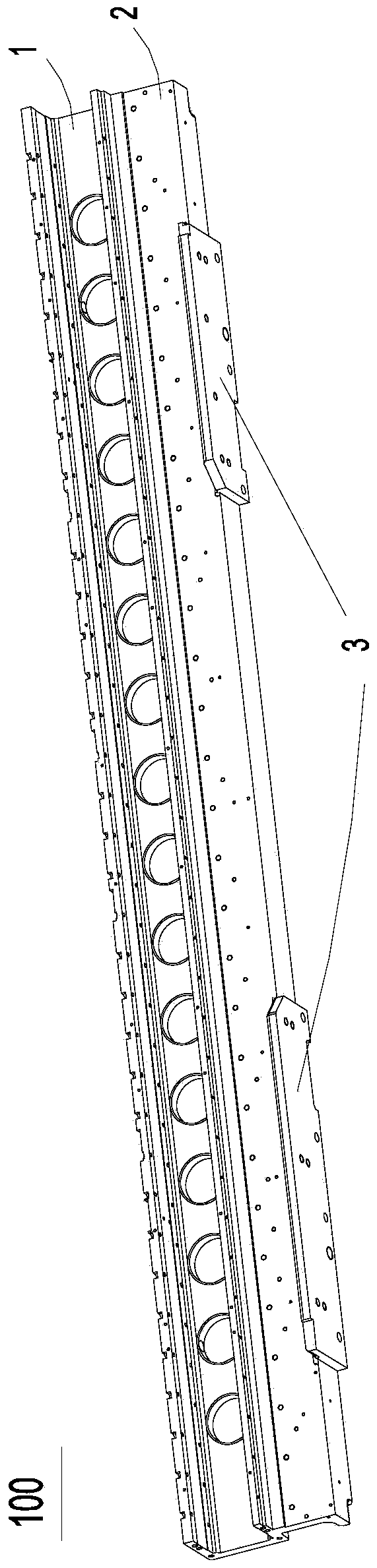

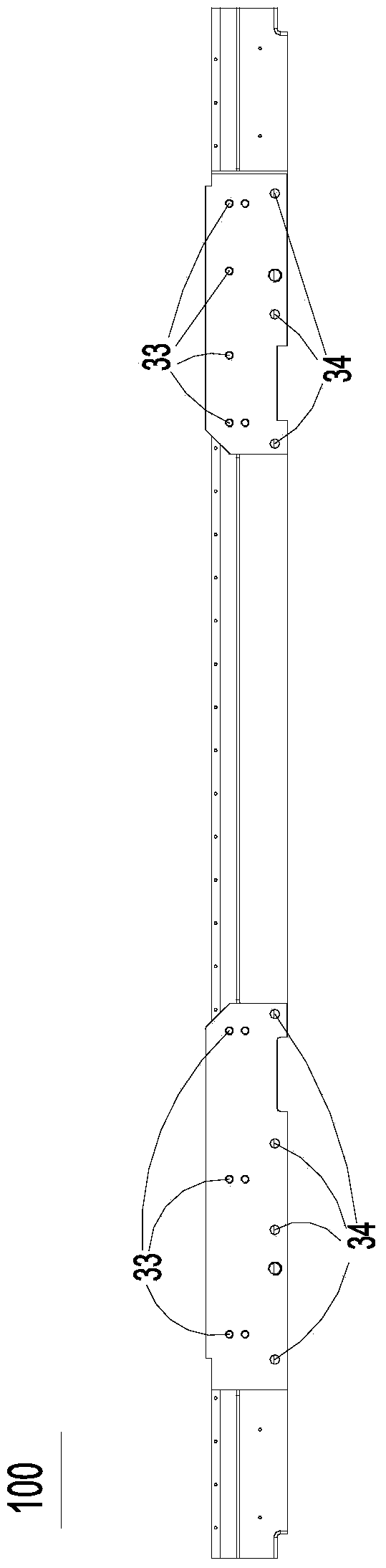

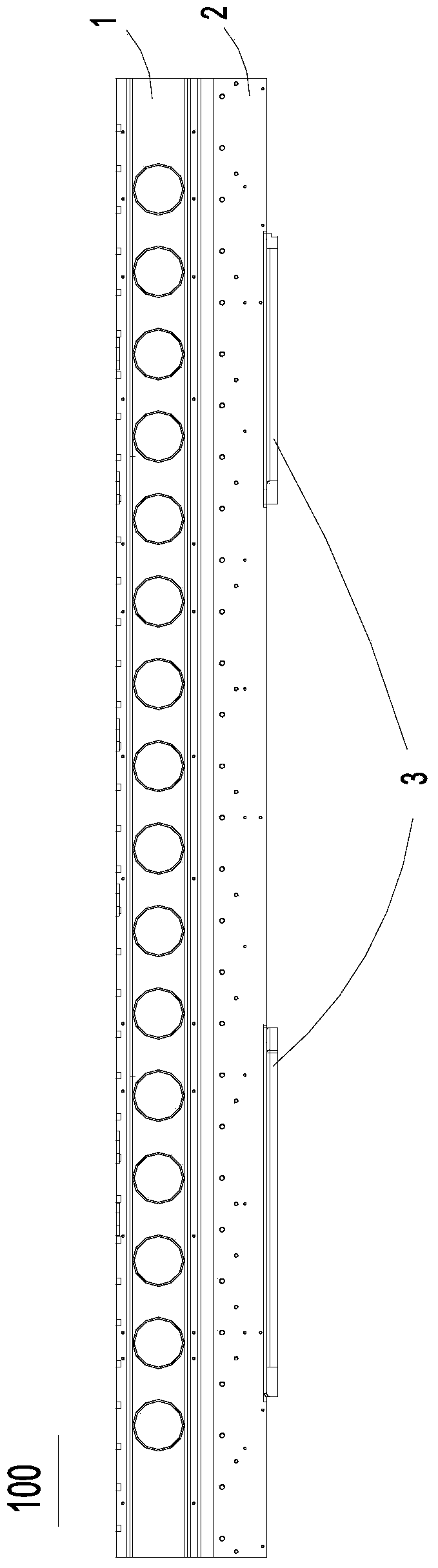

Method of manufacturing bonded-magnet rotor

ActiveUS9225212B2Reduce a phase misalignment of the pole positionsPrecise positioningMagnetic circuit rotating partsPermanent magnetsEngineeringMagnet

A method of manufacturing a bonded-magnet rotor according to the invention includes forming step and arranging step. The forming step is by forming a bonded-magnet formed body. The arranging step includes: integrating an inside-diameter holding jig, a rotor core, and a rotor-core presser jig; arranging the bonded-magnet formed bodies on the outside periphery of the inside-diameter holding jig; and arranging an outside-diameter-holding magnet-pressure-welding jig to support outside peripheral faces of the bonded-magnet formed bodies. The method further includes steps of: deforming the bonded-magnet formed bodies to fit with the outside peripheral dimension of the rotor core by pressing and transferring the bonded-magnet formed bodies to the rotor core with a forming jig; mutually joining end portions of adjacent ones of the bonded-magnet formed bodies; and integrating the bonded-magnet formed bodies with the rotor core by compressing the bonded-magnet formed bodies. This configuration allows the bonded-magnet rotor with high dimension accuracy.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method of machining guide seat of placement machine with gantry pentahedron CNC machine tool

InactiveCN104439897BReduce investmentHigh precision sizeMeasurement/indication equipmentsPositioning apparatusNumerical controlEngineering

The invention discloses a method for machining a chip mounter guide rail seat through a gantry pentahedron numerical control machine tool. The method comprises the steps that the gantry pentahedron numerical control machine tool is firstly utilized for carrying out rough machining on a green body and machining the faces, corresponding to groove opening faces, of the green body to form a rough locating face; then, the green body is located and clamped with the rough locating face in the first procedure as the datum, side face semifinishing is carried out on the machine tool, and finish machining is carried out on the face corresponding to the rear side face to form a first locating face; the green body is located and clamped again with the first locating face as the standard, rough machining is carried out on the faces corresponding to the inner side groove faces of a sliding groove through the machine tool, and finish machining is carried out on the face corresponding to the lower bottom faces of connecting portions of the green body and the face corresponding to the front side faces of the connecting portions to form a second locating face and a standard face respectively; finally, the green body is located and clamped again with the second locating face as the fine datum face, and finish machining is carried out on holes and the faces corresponding to all the inner side groove faces of the sliding groove. The high-precision size can be machined successfully, and it is guaranteed that the machining quality of the chip mounter guide rail seat is stable 100 percent.

Owner:SUZHOU IND PARK ELECTROMECHANICAL EQUIP

Integral advancing scraping and rolling compound cutter for flexibly boring, scraping and rolling

ActiveCN103028748BEliminate errorsSimple structureTurning toolsOther manufacturing equipments/toolsEngineeringMachining time

The invention discloses an integral advancing scraping and rolling compound cutter for flexibly boring, scraping and rolling. A scraping head, a boring head and a rolling head are integrated, and scraping and rolling processing are performed during advancing. The integral advancing scraping and rolling compound cutter is simple in overall structure, is convenient to manufacture, and is low in cost; high-accuracy size and shape control and good guidance can be realized, scraping becomes smoother, and wave marks and errors on a processing surface of an inner hole in a previous procedure can be eliminated, so that a completed surface becomes smoother, and a better surface profile is formed; and moreover, a plurality of processing procedures are completed continuously, so that processing time is saved.

Owner:宁波市精恒凯翔机械有限公司

Roll-extrusion combined near-net-shaping method for rings with sudden changes in outer contour

ActiveCN113084054BInhibit growthPrevent axial movementGeometric CADSpecial data processing applicationsStructural engineeringMechanical engineering

The invention discloses a method for rolling, extruding and compounding near-net forming of a large-scale outer contour sudden cross-section ring, comprising the steps of: S1. Pre-rolling the blank after upsetting and punching to obtain a ring blank with a uniform wall thickness and a large-diameter rectangular cross-section ; S2, place the pre-rolled ring blank on the extrusion die. The extrusion die includes a core die with limit flanges at both ends and a number of lobe dies evenly distributed around the axis, and the lobe dies are set along the axial direction. There are multiple stages of extrusion blocks, and each stage of extrusion blocks is controlled by its own high-pressure push rod. Multi-directional continuous local incremental radial extrusion is used to form the abrupt contour of the outer surface of the ring blank step by step along the axial direction to obtain special shapes. Ring blank; S3. The target ring is obtained by forming the special-shaped ring blank through radial closed near net rolling. The method has smaller forming force and lower energy consumption, can restrain the outer diameter of the ring from growing, has high material utilization rate, and greatly improves the comprehensive performance of the product.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com