A kind of processing method of wedge-shaped plate forging

A processing method and wedge-shaped plate technology, which are applied in the field of steel forging, can solve the problems of easily damaged jaw hydraulic system, high requirements on presses, poor internal quality, etc., so as to improve the quality of the core, reduce the forging allowance, Good effect of metal fiber organization streamline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

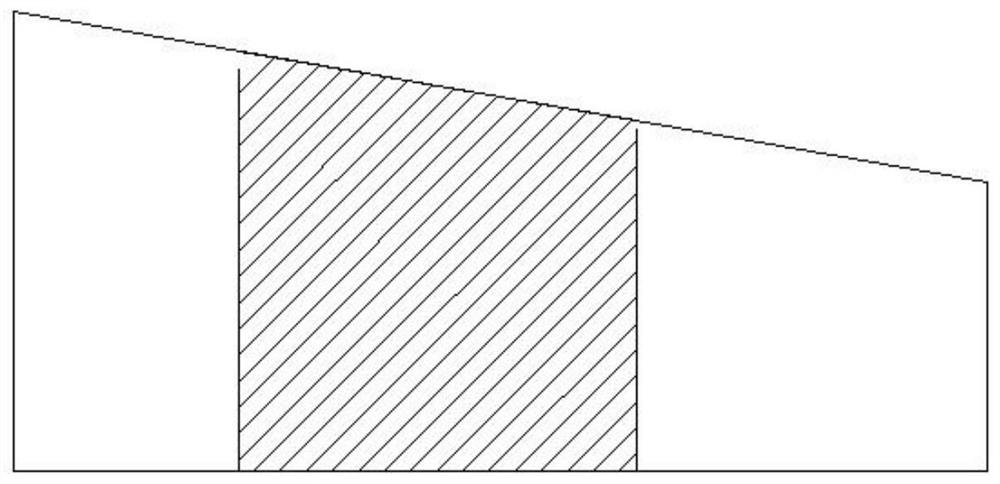

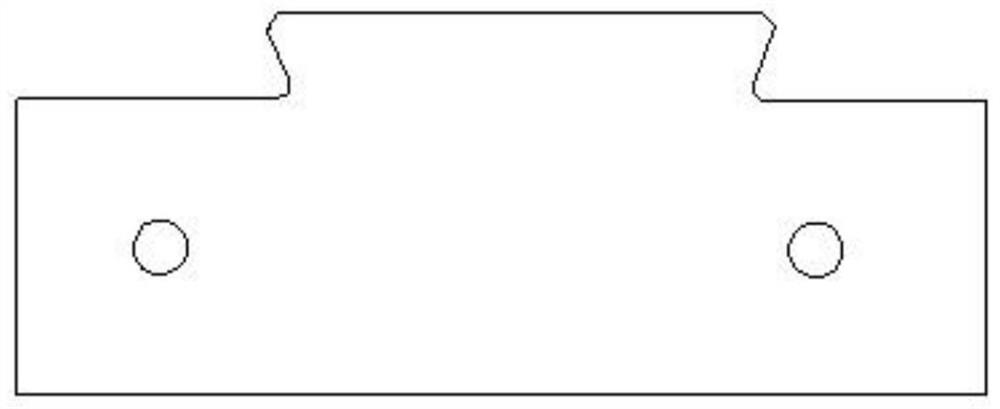

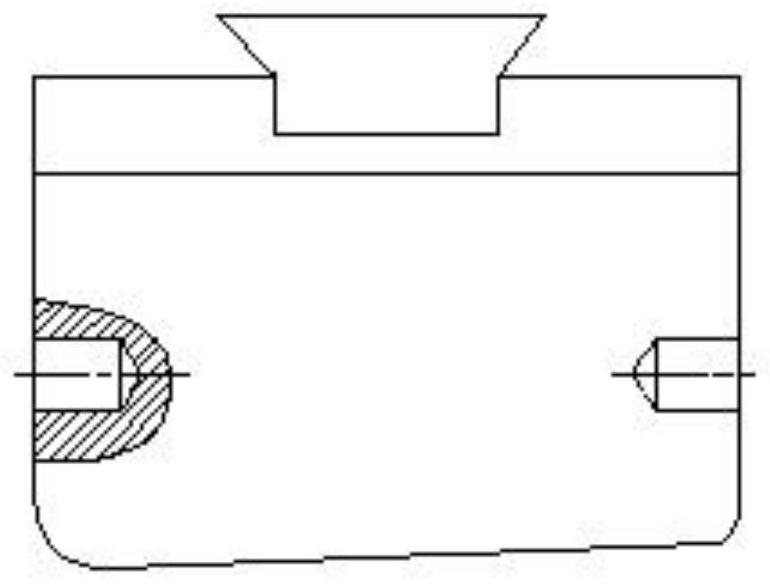

[0024] A processing method for a wedge-shaped plate forging, the technological process of the processing method for a wedge-shaped plate forging is as follows: heating the steel ingot → pressing the jaw → chamfering → removing the bottom of the ingot → upsetting for the first time → drawing a rectangular blank for the first time → The second upsetting → The second drawing of the rectangular blank → The third drawing of the rectangular blank → Half-die forging with a special upper anvil → Heat treatment → Finishing each part to the finished product size, the special upper anvil is an upper flat slope Anvil, the angle between the bottom edge of the upper flat slope anvil and the horizontal plane is the same as the wedge angle of the wedge plate forging.

[0025] The processing method of a wedge-shaped plate forging described in this embodiment, in the processing method of a wedge-shaped plate forging, a 30MN hydraulic press is used for forging, and the steel ingot weighs 9.3 tons...

specific Embodiment approach 2

[0040] A processing method for a wedge-shaped plate forging, the technological process of the processing method for a wedge-shaped plate forging is as follows: heating the steel ingot → pressing the jaw → chamfering → removing the bottom of the ingot → upsetting for the first time → drawing a rectangular blank for the first time → The second upsetting → The second drawing of the rectangular blank → The third drawing of the rectangular blank → Half-die forging with a special upper anvil → Heat treatment → Finishing each part to the finished product size, the special upper anvil is an upper flat slope Anvil, the angle between the bottom edge of the upper flat slope anvil and the horizontal plane <1° of the wedge angle of the wedge plate forging.

[0041] The processing method of a wedge-shaped plate forging described in this embodiment, in the processing method of a wedge-shaped plate forging, a 30MN hydraulic press is used for forging, and the steel ingot weighs 9.3 tons.

[00...

specific Embodiment approach 3

[0052] A processing method for a wedge-shaped plate forging, the technological process of the processing method for a wedge-shaped plate forging is as follows: heating the steel ingot → pressing the jaw → chamfering → removing the bottom of the ingot → upsetting for the first time → drawing a rectangular blank for the first time → The second upsetting → The second drawing of the rectangular blank → The third drawing of the rectangular blank → Half-die forging with a special upper anvil → Heat treatment → Finishing each part to the finished product size, the special upper anvil is an upper flat slope Anvil, the angle between the bottom edge of the upper flat slope anvil and the horizontal plane is less than 2° of the wedge angle of the wedge plate forging.

[0053] The processing method of a wedge-shaped plate forging described in this embodiment, in the processing method of a wedge-shaped plate forging, a 30MN hydraulic press is used for forging, and the steel ingot weighs 9.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com