A Method for Determining the Shape and Dimensions of Variable-thickness Slabs for Bulkhead Forgings

A technology of variable thickness and forging, applied in metal processing equipment and other directions, can solve the problems of inability to achieve accurate and reasonable distribution of slabs, metal transverse rib flow, product quality cannot be guaranteed, etc., to eliminate the phenomenon of rib flow and reduce forging. The effect of the margin and the elimination of the outcropping of the streamline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

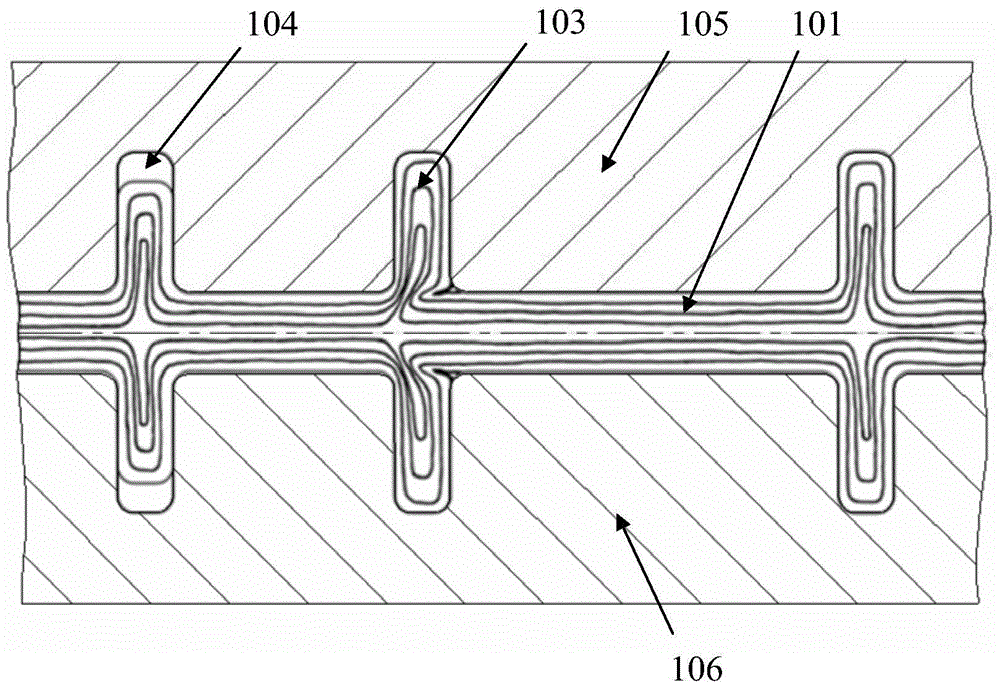

[0045] For the definition of web 101, peripheral rib 102 and middle rib 103 in the bulkhead forging described in the present invention, see pages 79 and 786 of Forging Technology Manual (Volume 1), National Defense Industry Press (first edition in 1989).

[0046] In this embodiment, the following steps are followed in order to accurately determine the shape and size of the variable-thickness slab for the bulkhead forging:

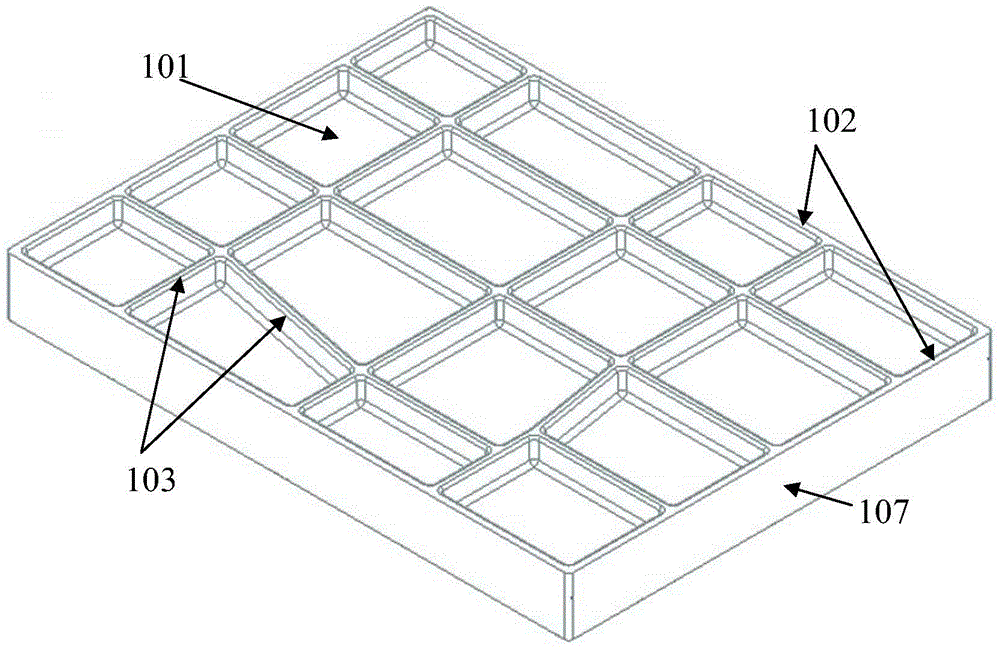

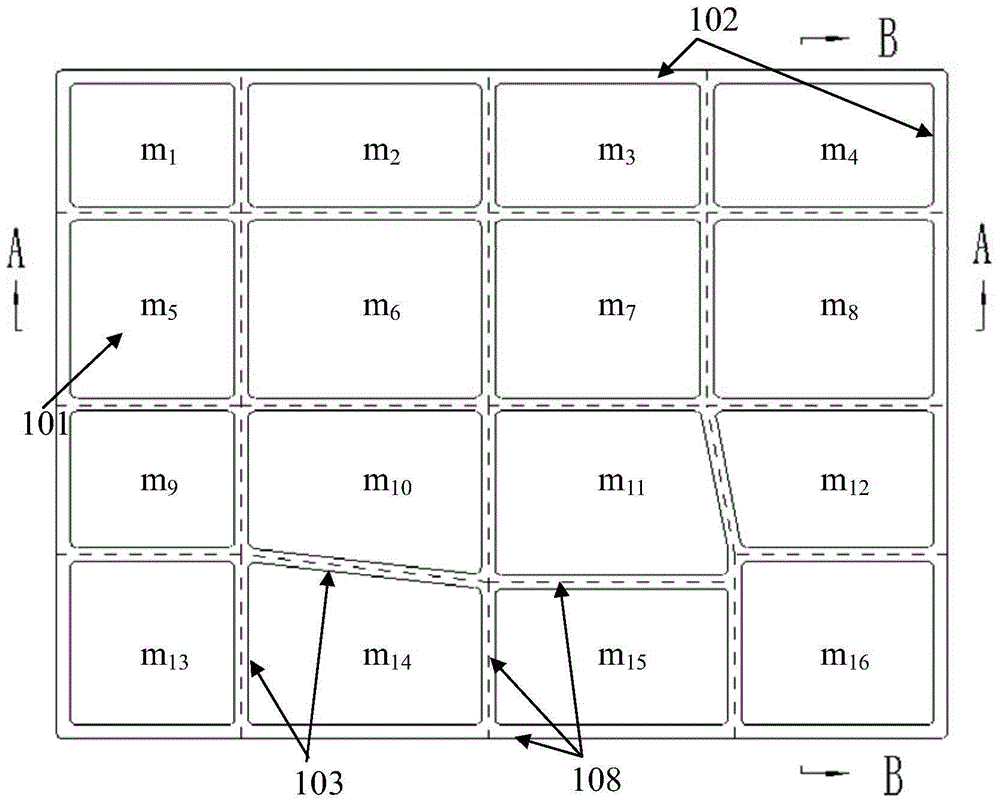

[0047]1) The bulkhead forging piece 107 is 650mm long and 490mm wide. It is a double-sided symmetrical rib structure, with 5 ribs interlaced in the vertical and horizontal directions. The rib width is 10mm, and the rib height on one side is 30mm. degree, the thickness of the web 101 is 15mm, and the total area of its plan view is 318480mm 2 . Use the modeling software UG to draw the three-dimensional modeling of the frame forging part 107, as shown in the attached figure 2 shown.

[0048] 2), use the computer drawing software CAXA electronic drawing b...

Embodiment 2

[0069] For the definition of web 101, peripheral rib 102 and middle rib 103 in the bulkhead forging described in the present invention, see pages 79 and 786 of Forging Technology Manual (Volume 1), National Defense Industry Press (first edition in 1989).

[0070] In this embodiment, the following steps are followed in order to accurately determine the shape and size of the variable-thickness slab for the bulkhead forging:

[0071] 1) The frame forging part 2 109 is 555mm long and 150-400mm wide. It is a double-sided symmetrical rib structure. There are 5 vertical ribs and 3 horizontal ribs interlaced with each other. The rib width is 10mm. The height of the rib 102 is 30mm, the height of the single lateral middle rib 103 is 26mm, there is no forging slope, the thickness of the web 101 is 15mm, and the total area of the plan view is 134006mm 2 . Use the modeling software UG to draw the three-dimensional modeling of the frame forging part 2 109, as shown in the attached Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com