Wind power hollow main shaft inner hole extruding and expanding forming process

A technology of hollow spindle and forming process, which is applied in the direction of manufacturing tools, piercing presses, metal processing equipment, etc., and can solve the problems of difficult repair, waste of raw materials, and large forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

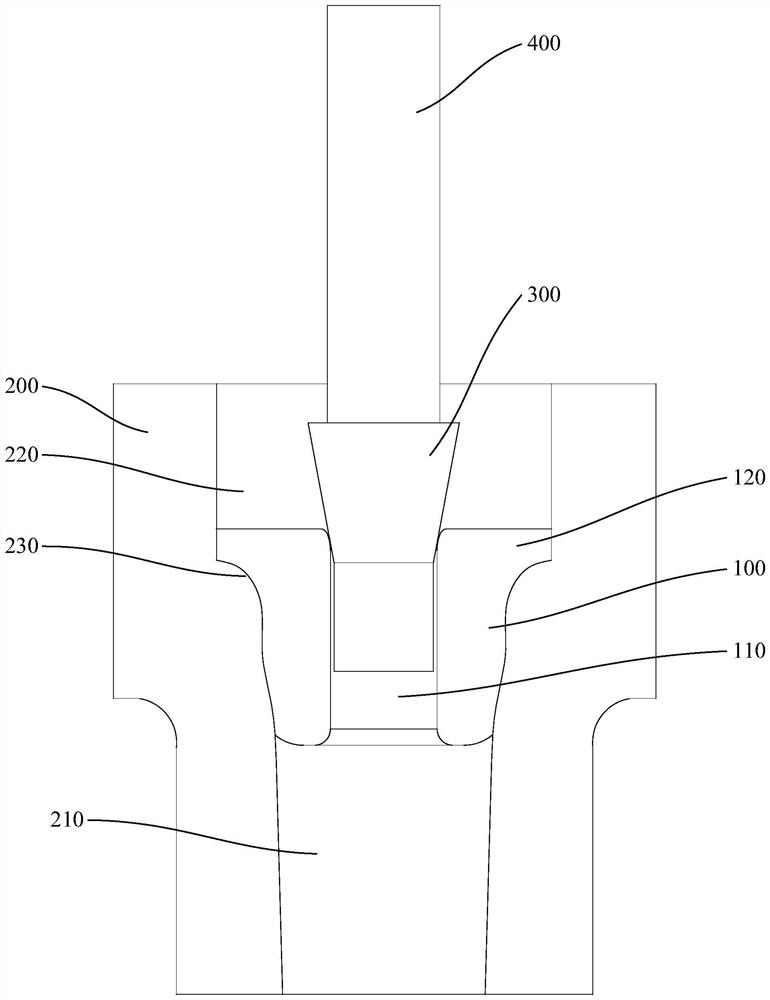

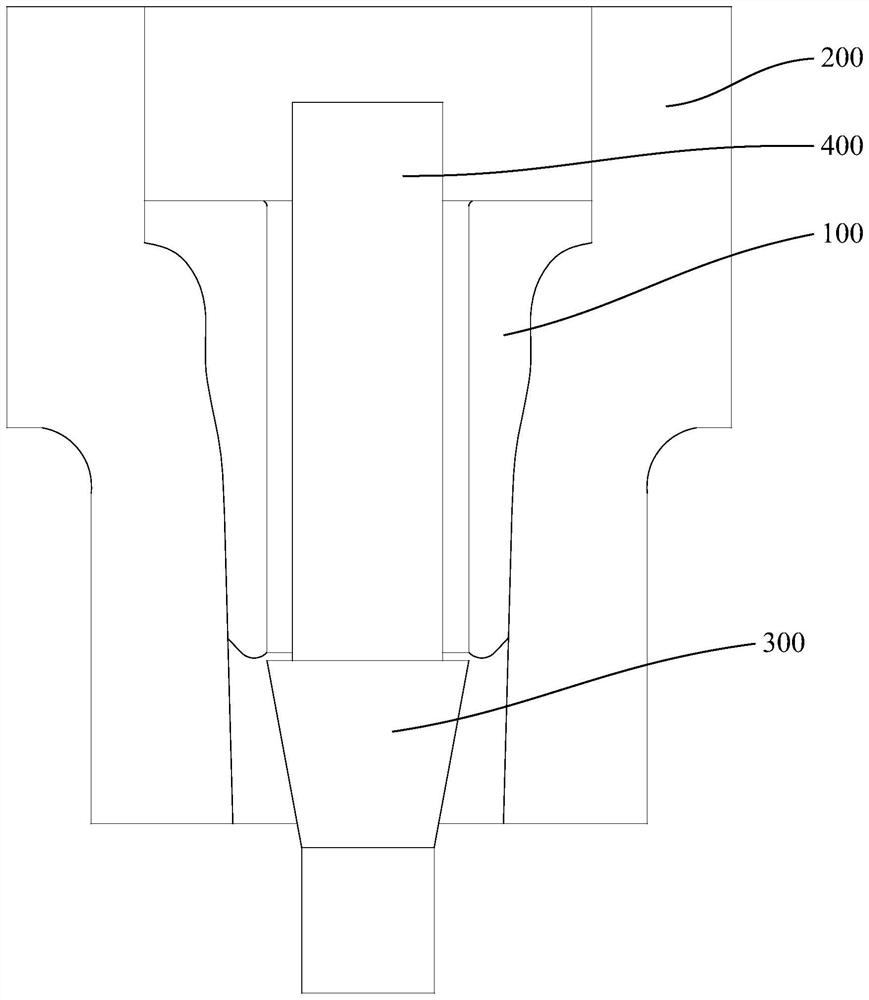

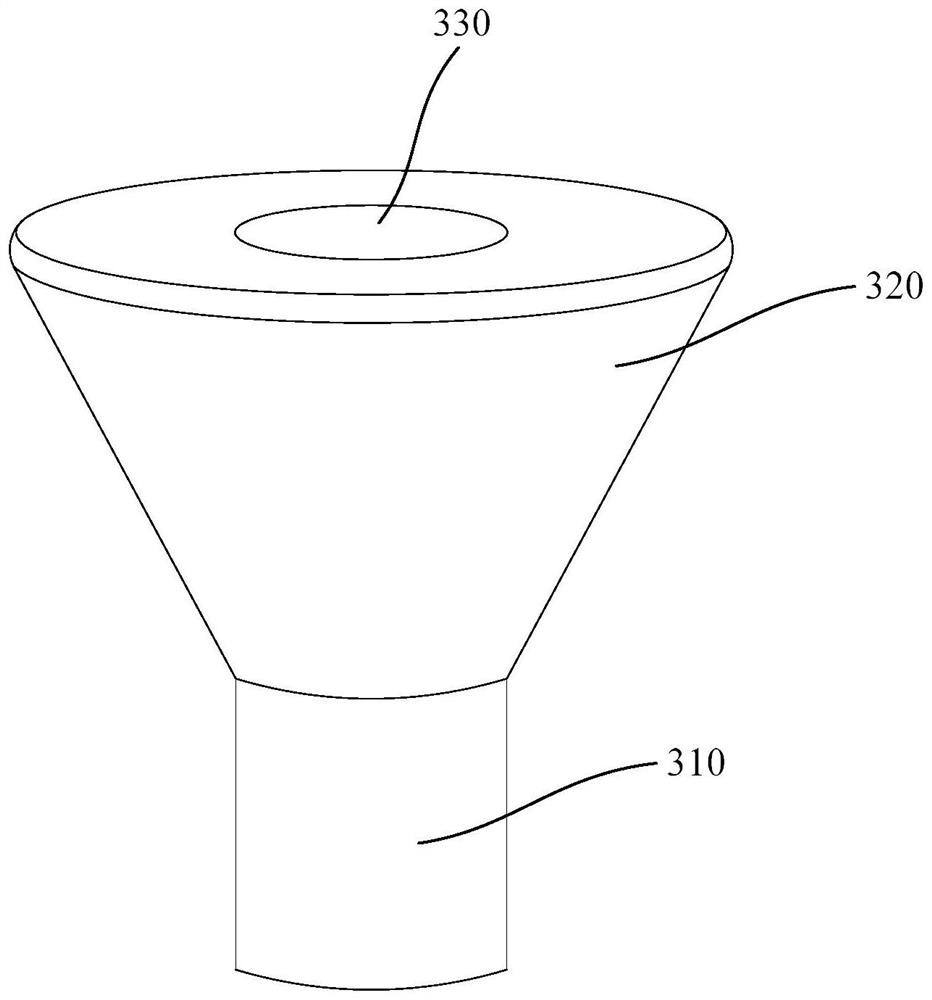

[0051] Prepare a 3MW wind power hollow main shaft, the diameter of the through hole 110 of the blank 100 is 460 mm, the length of the guide slope 130 is 210 mm, the diameter of the guide part 310 of the extruding tool 300 is 450 mm, the The obtuse angle formed by the side surface of the extruded part 320 and the side surface of the guide part 310 is 155°, and the length of the side surface of the extruded part 320 is 600 mm. Lubricant is applied on the inner surface of the forming die 200 and the outer surface of the extruding tool 300 .

[0052] Heat the blank 100 to above 1220°C, put the blank 100 into the forming mold 200, match the flange end 120 of the blank 100 with the positioning groove 220, and place the extrusion The expanding tooling 300 is inserted into the through hole 110 of the flange end 120, and then the connecting part 410 of the extruding tooling 400 is connected with the connecting hole 330 of the extruding tooling 300 . Use an extruder to press down the ...

Embodiment 2

[0054] Prepare a 3MW wind power hollow main shaft, the diameter of the through hole 110 of the blank 100 is 480mm, the length of the guide slope 130 is 220mm, the diameter of the guide part 310 of the extruding tool 300 is 475mm, the The obtuse angle formed by the side surface of the extruded part 320 and the side surface of the guide part 310 is 145°, and the length of the side surface of the extruded part 320 is 600 mm. Lubricant is applied on the inner surface of the forming die 200 and the outer surface of the extruding tool 300 .

[0055] Heat the blank 100 to above 1220°C, put the blank 100 into the forming mold 200, match the flange end 120 of the blank 100 with the positioning groove 220, and place the extrusion The expanding tooling 300 is inserted into the through hole 110 of the flange end 120, and then the connecting part 410 of the extruding tooling 400 is connected with the connecting hole 330 of the extruding tooling 300 . Use an extruder to press down the ext...

Embodiment 3

[0057] Prepare a 3MW wind power hollow main shaft, the diameter of the through hole 110 of the blank 100 is 470 mm, the length of the guide slope 130 is 200 mm, the diameter of the guide part 310 of the extrusion tooling 300 is 460 mm, the The obtuse angle formed by the side surface of the extruded part 320 and the side surface of the guide part 310 is 155°, and the length of the side surface of the extruded part 320 is 600 mm. Lubricant is applied on the inner surface of the forming die 200 and the outer surface of the extruding tool 300 .

[0058] Heat the blank 100 to above 1220°C, put the blank 100 into the forming mold 200, match the flange end 120 of the blank 100 with the positioning groove 220, and place the extrusion The expanding tooling 300 is inserted into the through hole 110 of the flange end 120, and then the connecting part 410 of the extruding tooling 400 is connected with the connecting hole 330 of the extruding tooling 300 . Use an extruder to press down t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com