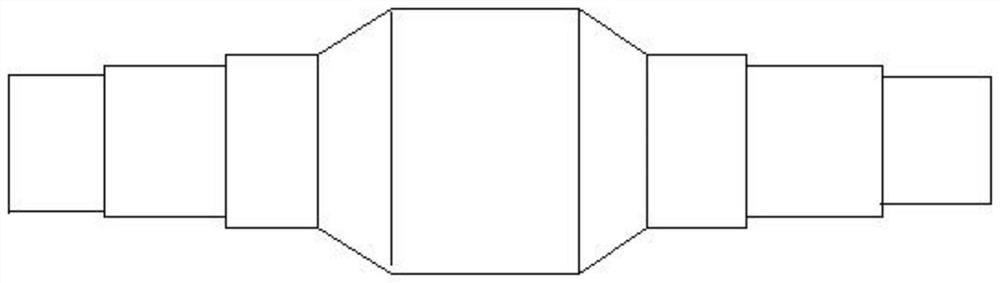

Forging method of multi-step roller with circular truncated cone

A conical truss and step technology, applied in the field of multi-step roll preparation, can solve the problems of waste of raw materials, long machining time, large forging allowance, etc., to reduce the difficulty of operation, improve the quality of the core, and improve the metal streamline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

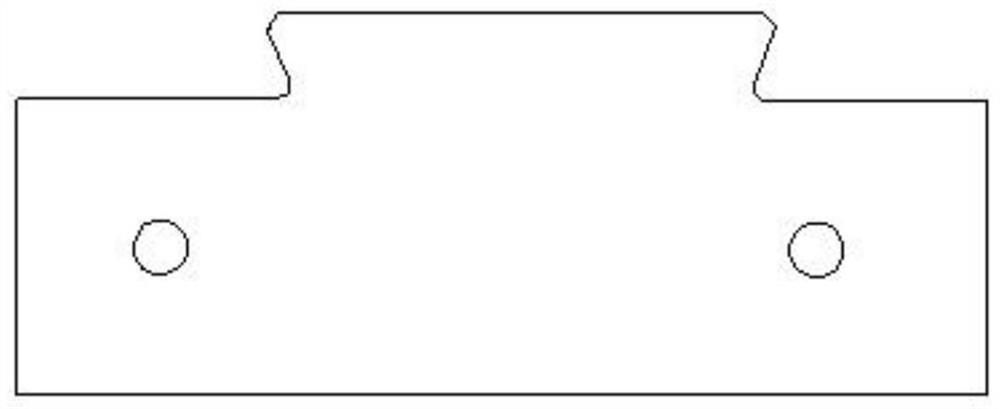

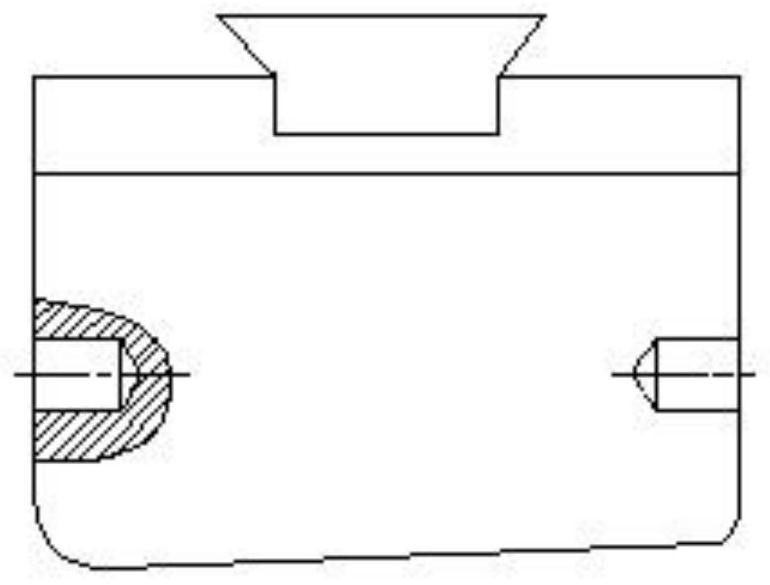

[0027] A forging method of a multi-stage stepped roll with a conical truncated roll, the process flow of the forging method of a multi-stage stepped roll with a conical truncated truncated steel ingot → press the jaw → first upsetting → first time Drawing the oblong billet → upsetting for the second time → drawing the oblong billet for the second time → drawing the oblong billet for the third time → half-die forging with a special upper anvil → pressing table, finishing each part to the finished product size → For heat treatment, the special-purpose upper anvil is an upper flat-slope anvil, and the angle between the bottom edge of the upper flat-slope anvil and the horizontal plane is equal to the angle of the truncated cone of a multi-stage stepped roll with a truncated cone.

[0028] The forging method of a multi-stage stepped roll with a conical truncated roll described in this embodiment adopts a 30MN hydraulic press for forging, and the steel ingot weighs 10.3 tons.

[00...

specific Embodiment approach 2

[0043] A forging method of a multi-stage stepped roll with a conical truncated roll, the process flow of the forging method of a multi-stage stepped roll with a conical truncated truncated steel ingot → press the jaw → first upsetting → first time Drawing the oblong billet → upsetting for the second time → drawing the oblong billet for the second time → drawing the oblong billet for the third time → half-die forging with a special upper anvil → pressing table, finishing each part to the finished product size → For heat treatment, the special-purpose upper anvil is an upper flat-slope anvil, and the angle between the bottom edge of the upper flat-slope anvil and the horizontal plane is equal to the angle of the truncated cone of a multi-stage stepped roll with a truncated cone.

[0044] The forging method of a multi-stage stepped roll with a conical truncated roll described in this embodiment, the described forging method of a multi-stage stepped roll with a conical truncated ro...

specific Embodiment approach 3

[0056] A forging method of a multi-stage stepped roll with a conical truncated roll, the process flow of the forging method of a multi-stage stepped roll with a conical truncated truncated steel ingot → press the jaw → first upsetting → first time Drawing the oblong billet → upsetting for the second time → drawing the oblong billet for the second time → drawing the oblong billet for the third time → half-die forging with a special upper anvil → pressing table, finishing each part to the finished product size → For heat treatment, the special upper anvil is an upper flat-slope anvil, and the angle between the bottom edge of the upper flat-slope anvil and the horizontal plane is ≤ the angle of the truncated cone of the multi-step roller with a truncated cone.

[0057] The forging method of a multi-stage stepped roll with a conical truncated roll described in this embodiment, the described forging method of a multi-stage stepped roll with a conical truncated roll adopts a 30MN hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com