A manufacturing method of fan-shaped plate forgings for reels of economical coilers

A manufacturing method and a fan-shaped plate technology, which are applied in the field of metallurgical machinery manufacturing, can solve the problems that the manufacturing cost of the fan-shaped plate affects the economic benefits of steel rolling, the complex forging cylinder process, and the inability to produce a single piece, so as to reduce the amount of raw materials and shorten the machining process. Time, production flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

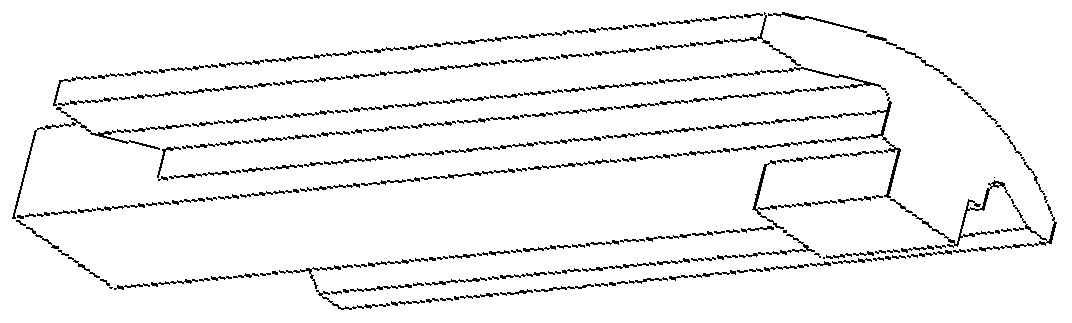

[0045] A method for manufacturing a fan-shaped plate forging for an economical coiler reel, comprising the following steps:

[0046] Step a, pouring the molten steel after converter smelting, LF furnace refining, and VD vacuum degassing into 42CrMoA continuous casting round billets, after off-line, fire-cutting, slow cooling, and standby;

[0047] Step b. Put the 42CrMoA casting continuous casting round billet obtained in step a into a gas heating furnace for heating, and then forge after being out of the furnace. For the first fire, use an upper flat anvil and a large platform for upsetting. After upsetting, the first Return to the furnace for heating for the first time, use the upper flat anvil and lower V-shaped anvil for forging for the second time of forging, and then return to the furnace for heating for the second time after drawing, and use the upper arc-shaped anvil and small platform for the third time of forging. fan-shaped, and then use the upper flat anvil and sma...

specific Embodiment approach 2

[0070] A method for manufacturing a fan-shaped plate forging for an economical coiler reel, comprising the following steps:

[0071] Step a, pouring the molten steel after converter smelting, LF furnace refining, and VD vacuum degassing into 42CrMoA continuous casting round billets, after off-line, fire-cutting, slow cooling, and standby;

[0072] Step b. Put the 42CrMoA casting continuous casting round billet obtained in step a into a gas heating furnace for heating, and then forge after being out of the furnace. For the first fire, use an upper flat anvil and a large platform for upsetting. After upsetting, the first Return to the furnace for heating for the first time, use the upper flat anvil and lower V-shaped anvil for forging for the second time of forging, and then return to the furnace for heating for the second time after drawing, and use the upper arc-shaped anvil and small platform for the third time of forging. fan-shaped, and then use the upper flat anvil and sma...

specific Embodiment approach 3

[0076] According to the manufacturing method of a saving-type coiler reel fan-shaped plate forging described in the second specific embodiment, the converter smelting in step a is equipped with a molten iron ratio ranging from 85% to 90%, and a steel scrap ratio of 10% to 15% %, tapping C content ≥ 0.20wt%, P content ≤ 0.005wt%, tapping temperature ≥ 1630°C, adding deoxidizer aluminum ingot 8Kg / t during tapping, adding compound refining slag 200-300Kg, lime 500- 700Kg, put 120Kg top slag modifier on the slag surface after tapping (composite refining slag: model: 1847-18-01-20, manufacturer Henan Xibao Smelting Material Group Co., Ltd.; top slag modifier: model 6438- 17-06-23, manufacturer: Yingkou Golden Lion Special Resistance Co., Ltd.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com