A processing method for producing multi-step cold-rolled work roll blanks by using a radial forging machine

A technology of cold-rolled work rolls and processing methods, which is applied to metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., and can solve problems such as high manufacturing costs, excessive forging residual blocks, and reduced profit margins. Achieve the effect of high production efficiency, low forging weight and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

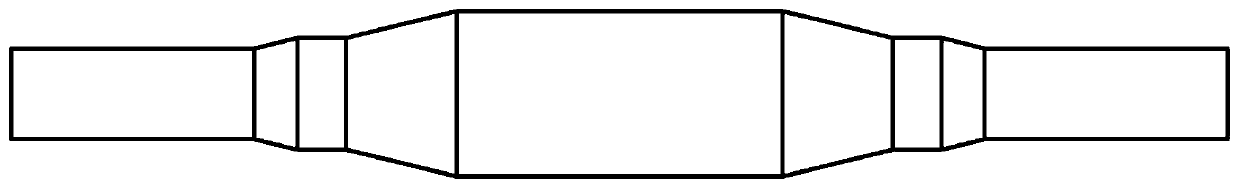

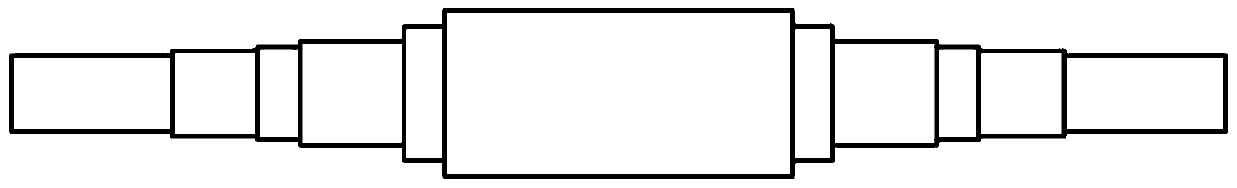

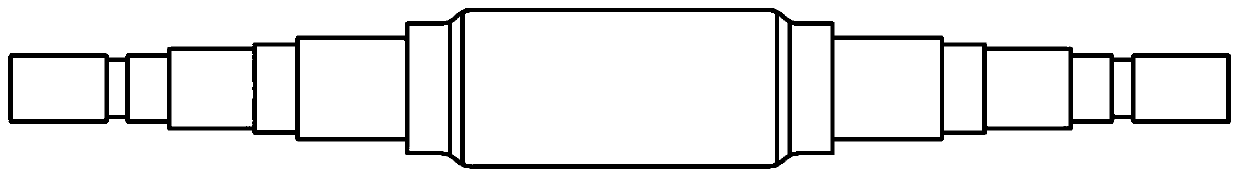

Image

Examples

specific Embodiment approach 1

[0032] A processing method for producing a multi-step cold-rolled work roll billet by using a radial forging machine, comprising the following steps:

[0033] Step a, pouring the molten steel after electric furnace smelting, LF furnace refining, and VD vacuum treatment into MC6B multi-step cold-rolled work roll billet electrode ingot;

[0034] Step b. The MC6B multi-step cold-rolled work roll billet electrode ingot prepared in step a is subjected to fire cutting, annealing, surface shot blasting, gas baking, and electroslag remelting to obtain MC6B multi-step cold-rolled work roll billet electroslag ingot ;

[0035] Step c, the MC6B multi-step cold-rolled work roll billet electroslag ingot prepared in step b is annealed, the surface is cleaned, and the gas furnace heating and holding time is ≧24h, and the MC6B multi-step cold-rolled work roll billet steel ingot is obtained for use;

[0036] Step d, the MC6B multi-step cold-rolled work roll billet steel ingot obtained in step ...

specific Embodiment approach 2

[0055] A processing method for producing a multi-step cold-rolled work roll billet by using a radial forging machine, comprising the following steps:

[0056] Step a, pouring the molten steel after electric furnace smelting, LF furnace refining, and VD vacuum treatment into MC6B multi-step cold-rolled work roll billet electrode ingot;

[0057] Step b. The MC6B multi-step cold-rolled work roll billet electrode ingot prepared in step a is subjected to fire cutting, annealing, surface shot blasting, gas baking, and electroslag remelting to obtain MC6B multi-step cold-rolled work roll billet electroslag ingot ;

[0058] Step c, the MC6B multi-step cold-rolled work roll billet electroslag ingot prepared in step b is annealed, the surface is cleaned, and the gas furnace heating and holding time is ≧24h, and the MC6B multi-step cold-rolled work roll billet steel ingot is obtained for use;

[0059] Step d, the MC6B multi-step cold-rolled work roll billet steel ingot obtained in step c ...

specific Embodiment approach 3

[0064] According to a processing method for producing multi-step cold-rolled work roll blanks with a radial forging machine described in the second specific embodiment, the electric furnace smelting in step a is that the proportion of molten iron or pig iron in each furnace is 30-32%, and the tapping temperature is 1640-300%. At 1700°C, carbon increase is completed in the tapping process, and alloy and slag are poured in when the tapping amount reaches 15-30 tons; in step a, LF furnace refining adds aluminum wire at 2-4m / t, and the amount of aluminum beans and carbon powder The dosage of the mixture is 1-1.5kg / t, and the white slag refining time is 20-25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com