A Forging Method for Reducing the Weight of Arched Plate Forgings for Coiler Drums

An arched plate and forging technology is applied in the field of forging to reduce the weight of arched plate forgings for coiler reels, and can solve the problems of excess blank forgings, high forging manufacturing cost, low production efficiency, etc. Small margin, improved production efficiency, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

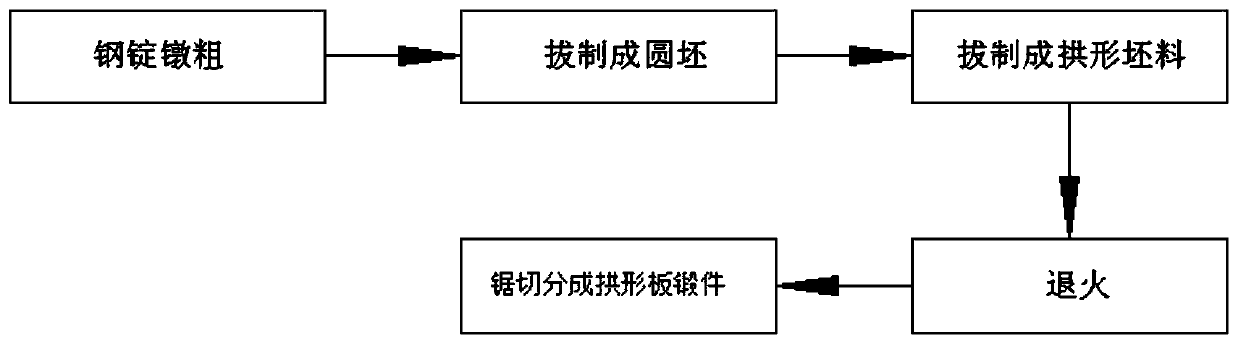

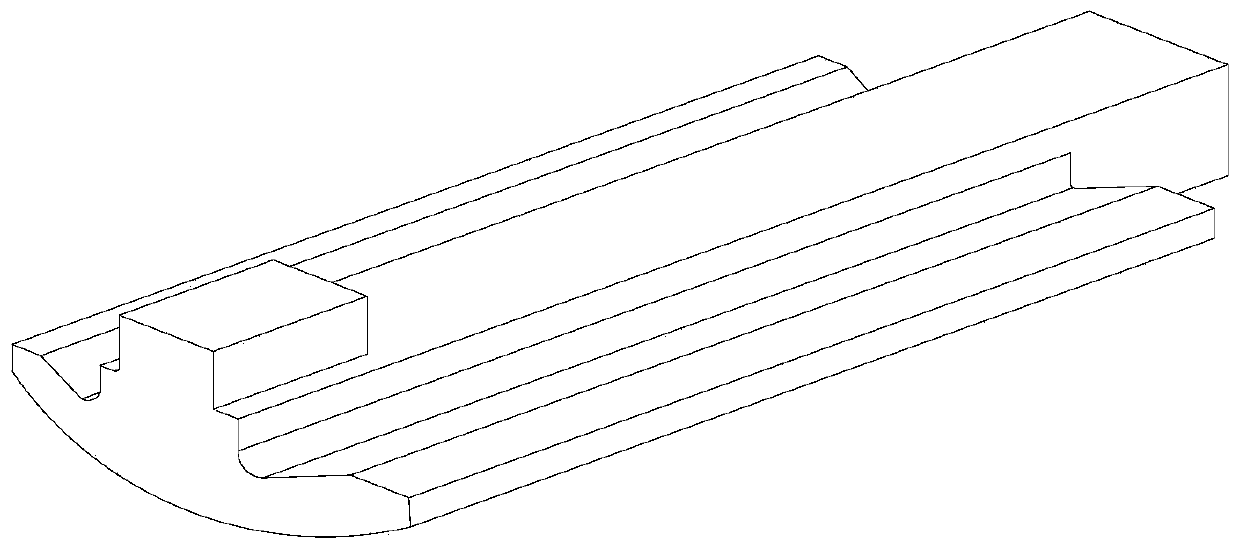

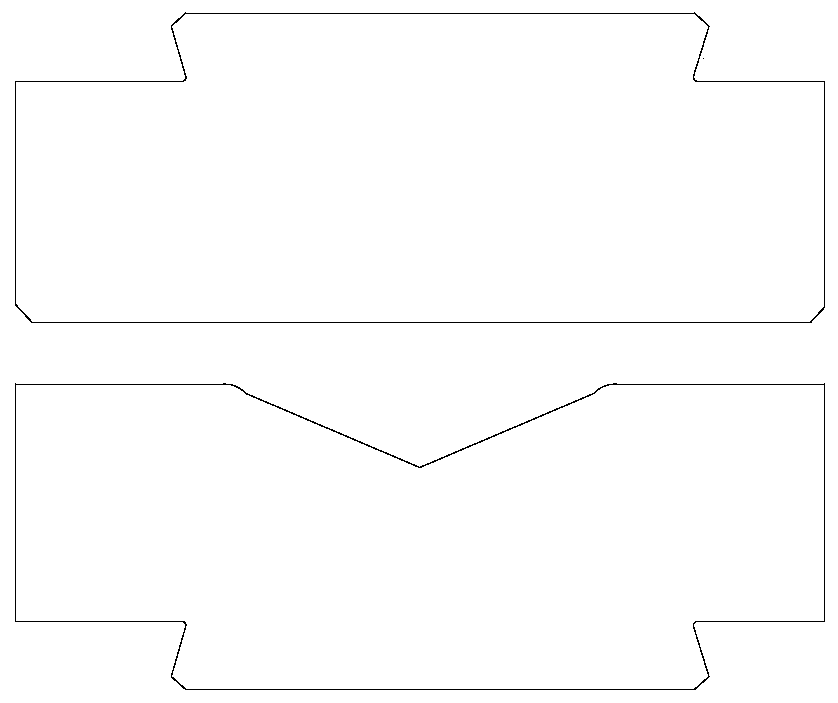

[0026] combine Figure 1-Figure 6 As shown, this embodiment discloses a forging method for reducing the weight of an arched plate forging for a reel of a coiler. The method includes the following steps:

[0027] Step a: Steel ingot upsetting: smelting by electric furnace, the proportion of molten iron or pig iron in each furnace is ≥30%, the tapping temperature is ≥1590°C, w[P]≤0.005%. During the tapping process, add 40kg of deoxidizer aluminum ingot and calcium carbide each, add compound refining slag according to ≥200kg per furnace, add lime ≥80kg per furnace, and put 80kg of top slag modifier on the slag surface after tapping; The oxidized slag is brought down; the following slag must be slag dumped and slag removed; after the smelting is completed, it enters the LF furnace for refining, and the molten steel is fed to the LF furnace refining station to feed the aluminum wire at a distance of 200 to 300 meters. The refining process uses Al particles and C powder to diffuse ...

Embodiment 2

[0038] A specific embodiment of a forging method for reducing the weight of an arched plate forging for a reel of a coiler comprises the following steps:

[0039] Step 1: electric furnace smelting: the ratio of molten iron or pig iron to each furnace is ≥30%.

[0040] Step 2: Tapping temperature ≥ 1590°C, [P] ≤ 0.005%. During the tapping process, add 40kg of deoxidizer aluminum ingot and calcium carbide, add compound refining slag at a rate of ≥200kg per furnace, add lime ≥80kg per furnace, and put 80kg of top slag modifier on the slag surface after tapping.

[0041] Step 3: It is strictly forbidden to take off the oxide slag when the steel is tapped from the primary smelting furnace. The following slag must be slag dumped and slag removed.

[0042]Step 4: Feed the molten steel to the refining station of the LF furnace with aluminum wires of 200 to 300 meters. During the refining process, Al particles and C powder are used for diffusion deoxidation, and Cr-Fe alloys, Mo-Fe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com