Die tooling and forging method of straight pipe forging billet for nuclear power main pipeline

A technology for main pipes and forging blanks, which is applied in the field of die tooling and forging of straight pipe forging blanks for nuclear power main pipes, can solve the problems of easy cracking, long production cycle, long crack cleaning cycle, etc. The effect of quantity, control and refinement of grains, shortening of processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Please refer to Figure 4 , a die tooling for a straight pipe forging billet for a nuclear power main pipeline, used for forging a straight pipe forging billet for a nuclear power main pipe, the straight pipe forging billet for a nuclear power main pipe includes a nozzle 4, a nozzle flange 5, and a pipe body 6, Both ends of the tube body 6 are provided with rounded corners 7 .

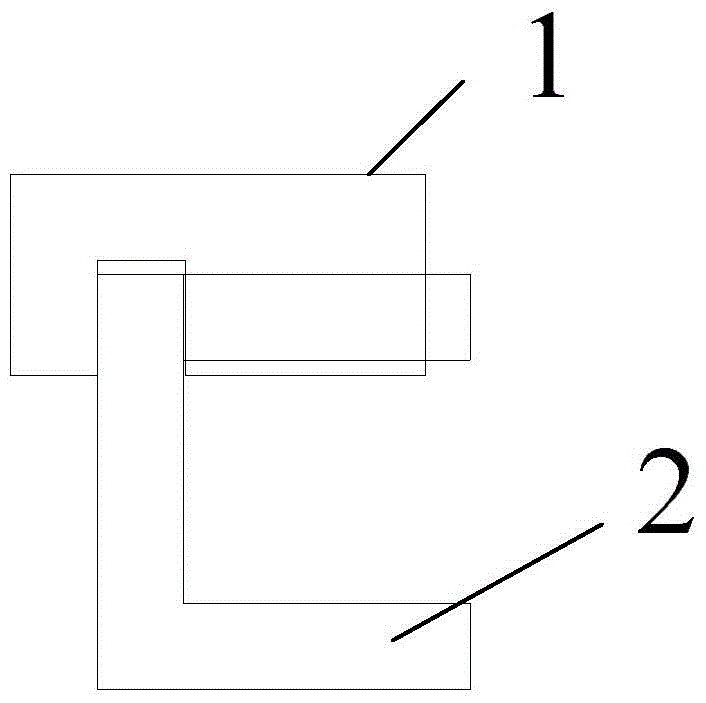

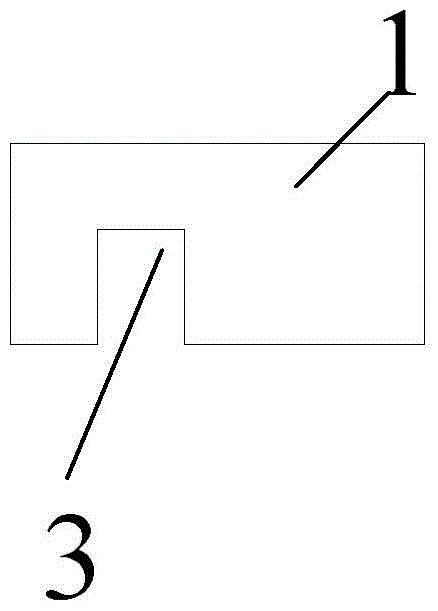

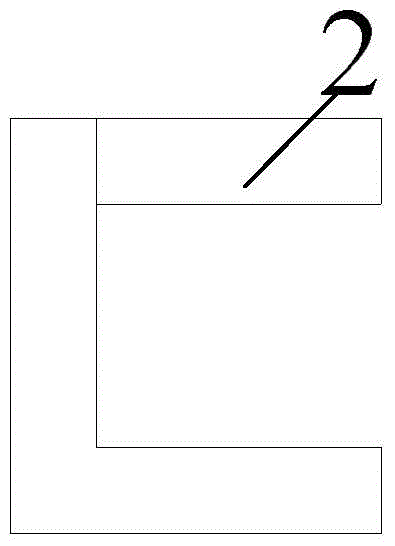

[0032] Please refer to Figure 1a to Figure 1c , the die tooling of the straight pipe forging billet for nuclear power main pipelines includes an upper die 1 for forging anvils and a lower die 2 for trimming nozzles 4, and the upper die 1 and the lower die 2 pass through the positioning groove 3 Match connection. The positioning groove 3 is arranged on the upper mold 1 , and may also be arranged on the lower mold 2 .

[0033] Please refer to figure 2 , a method for forging straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com